"Proud that we made no mistakes in such a mega-project"

At the start of autumn, mobility around Groningen regains its second breath thanks to the newly constructed southern ring road. The sheer scale and construction time of this 12-kilometer route renovation required meticulous geodesy and surveying, in the hands of engineering firm MUG under the auspices of senior project leader Marcel van der Wal.

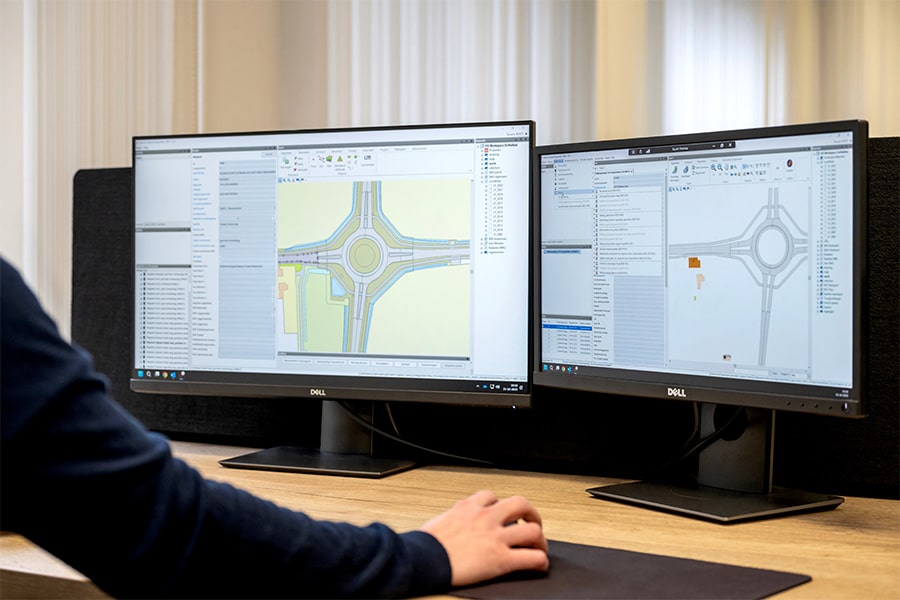

With 26 years of expertise in surveying, Marcel was recruited specifically to manage the dimensions of Aanpak Ring Zuid. He therefore led a 15-member survey team of dimensional surveyors, data processors and work planners who have been working on the civil construction portion of the project for eight years.

"Specifically, that includes the dimensioning of the concrete work for the structures, such as viaducts and tunnels, sheet pile walls, piles and tubular piles," Marcel explains. "In addition to studying the project requirements, the budget and providing the right construction solutions - with corresponding methods - the surveying basis is the most important thing during the preparatory phase. It is the capstone for the entire project. The permission to place the prisms for being able to measure with Total Station fortunately posed no problems. Then we were able to apply a secondary level over the entire 12-kilometer stretch."

In cooperation with Geomaat

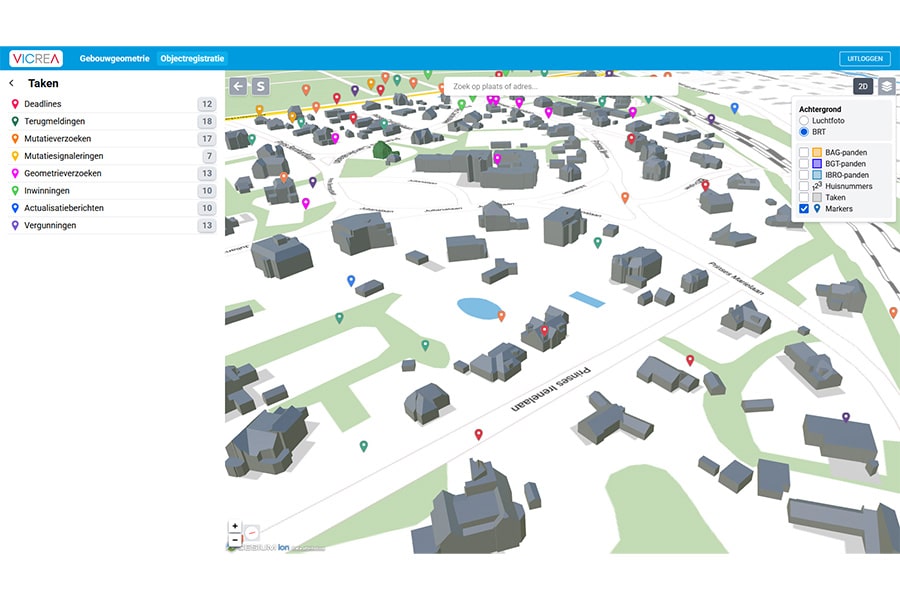

"With a ring project of this magnitude, you are working in different places at the same time and a lot of capacity is required. You can never do that alone. That's why we worked with Geomaat, which was responsible for the additional infrastructure part," Marcel explains. "But bringing structure to the sea of data via a sharepoint also proved to be a very successful approach." Although the initial surveying and data collection with subsequent processing were of course crucial in the realization of Aanpak Ring Zuid, the role of monitoring is at least as fundamental. "This involves deformation measurements at the buildings, pocket beacons, tracks, sheet piling and structures. We check that the work is not causing subsidence," Marcel said.

Deepening as biggest challenge

When asked what exactly were the "specials" of this particular project, the project leader replied, "Without question, the fitting of the pre-construction locations on the structures, the moment when the dimensions and construction work come together. Ditto for entering the railroad deck and the Helperzoomtunnel. Moments like these are the crowning glory of work that remains very exciting despite the control measurements. As an engineering firm, you not only calculated those works, but you also direct that event. I am very proud that our team did not make any mistakes. But I also do everything in my power to keep an overview and avoid something like that. But the undoubtedly biggest challenge was the sunken location with a distance of 1,200 meters and a pile plan of some 8,000 pieces."

As a modern engineering firm, MUG deploys high-performance technology such as static 3D scanners (Leica RTC 360) for reading in the existing structures, among other things. Mobile mapping via lidar, drones, aircraft, GPS data collection and classical total stations also complement the arsenal of measurement tools. "We deploy these purposefully, because from the digital terrain model we have learned that more measurement methods do not always yield better results with sometimes deviations of up to 6 centimeters. It's a matter of knowing exactly what to use where," Marcel said.