Steelwrist in demolition and recycling

Increased productivity, safety and cost effectiveness with SQ automatic quick couplers, adapters and end plates

In demolition projects, it is often common to change between different hydraulic attachments. When using an automatic quick coupler solution, where the hydraulic connection is integrated into the quick coupler, it is possible to change attachments without having to leave the excavator cab. This saves time and also costs, since fewer machines are needed.

On demolition sites, safety is critical and it is often necessary to avoid personnel in the demolition zone. Safety around the excavator increases when automatic quick couplers are used because personnel are no longer required to manually connect or disconnect attachments near heavy equipment.

Steelwrist has developed the SQ Auto connection system to meet the demands of the demanding demolition industry.

The core of the automatic quick-change technology is that it safely connects the implement and also connects the hydraulic couplings of the implement in an automatic manner.

SQ Automatic quick couplers

Steelwrist offers a complete range of SQ automatic quick couplers, all of which comply with the Open-S (OS®) symmetrical standard, for both mechanical, hydraulic and electrical interface. From the largest size, SQ90 - for excavators up to 70 tons, to the smallest quick coupler, SQ40 - for machines up to 7 tons.

Adapters and header plates

Many different pieces of equipment are available in the demolition industry, all specifically tailored to different stages of the demolition process.

For seamless integration with the SQ system, we offer a wide range of adapter plates for large demolition and high-performance hydraulic attachments.

The SQ automatic quick change, adapter plates and head plates provide a solution that allows all excavators within the same weight class to share demolition tools on different work sites without any problems.

What quick change size should I choose?

Important questions when selecting the right quick coupler are:

- What is the weight of the machine?

- What are the oil flow requirements?

- How many functions do the attachments have?

- Does the equipment need a leak line?

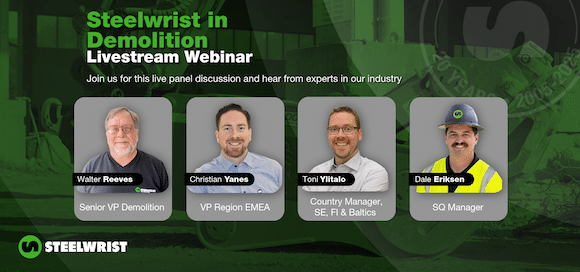

Watch the Steelwrist in Demolition webinar

Find out how the industry is making progress in safety, efficiency and innovation, and what role Steelwrist is playing in this transformation.

What you will learn:

- How automatic quick couplers improve safety in demolition operations

- How adapter plates increase efficiency

- The role of open standards in construction machinery

Where: YouTube & LinkedIn