ViaCon BCT offers strong, durable and efficient corrugated steel structures for the renovation of structures

In the decades following World War II, a tremendous number of engineering structures such as bridges, tunnels and culverts were constructed and are now in need of major maintenance or replacement. They are nearing the end of their lifespan or do not meet the requirements for the increased traffic intensity and load. ViaCon Bergschenhoek Civil Engineering (ViaCon BCT) offers various innovative, sustainable structures made of corrugated steel for the civil engineering sector.

"The complete replacement of aging bridges and culverts often causes major traffic disruption, long lead times and high costs," says Dick van der Linde of ViaCon BCT. "Our corrugated steel structures are a cost-effective and sustainable solution without major demolition or traffic detour, where the fast and efficient execution ensures minimal disruption to the surrounding area. They are therefore an attractive alternative."

From culvert pipe to traffic tunnel

The ViaCon Group operates in 19 countries in Europe and has extensive experience in renovating structures with corrugated steel. From a small culvert pipe to a large traffic tunnel. "Based on project-specific data, we examine whether the existing structure can be renovated with a ViaCon BCT solution. From our library of more than 400 standard culvert and tunnel profiles, we can suggest the best fitting profile for every situation. We advise, calculate, engineer, produce and deliver the construction. Of course we ensure that the designed profile meets the current requirements and standards for traffic loads," Dick continues.

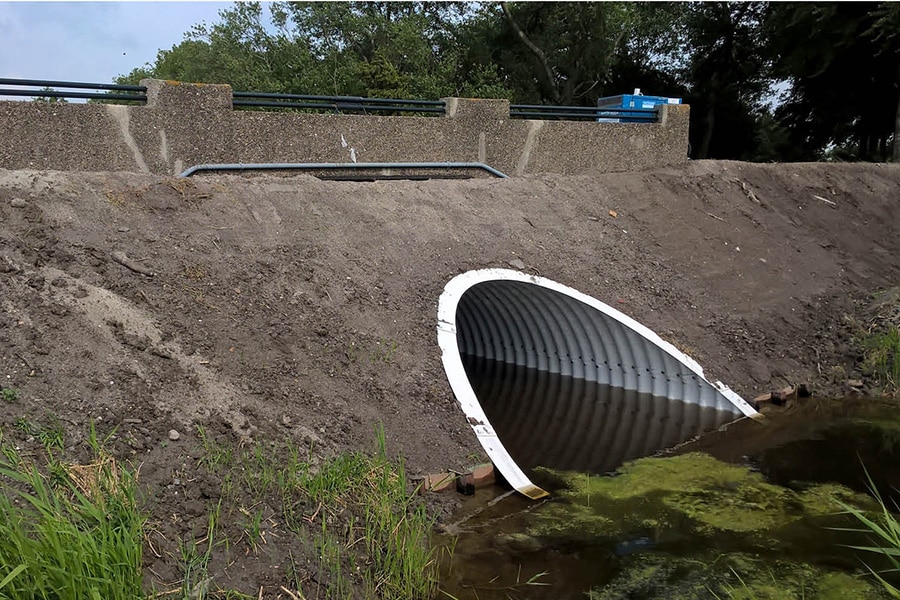

Renovation of a bridge by applying a muzzle profile culvert.

Pull-in or Build-in method

Dick explains ViaCon BCT's two commonly used methods, "In the Pull-in method, a new steel profile is pulled into the existing structure. This is commonly used when space is limited, such as under existing bridges. The Build-in method, on the other hand, is used when there is sufficient space to build and assemble a new structure into the existing one. It is also used in projects where the loss of flow area or the reduction of the profile of clearance must be minimized, or when the existing structure changes direction longitudinally." The corrugated steel sheet elements are tailored in terms of size and weight so that the entire process can be carried out by hand, and are fitted with flanges to finish them on the inside. "The special elements such as kinks and bends are accurately measured on site and prefabricated to size in the factory," Dick continues. In both methods, the gaps are filled with a semi-liquid filler that, once hardened, provides support pressure for the new tunnel.

ViaCon BCT always carries out a project in conjunction with a civil engineering contractor. "They take care of drying, cleaning and, if necessary, installing the slide beams and crane work, we take care of the rest."

Why replace when renovation is possible?

Renovation with corrugated steel offers many advantages: speed of construction, reduced environmental impact, upgrade of the structure's load-bearing capacity and significant cost savings. "In addition, it provides minimal disruption to the environment and traffic during renovation, as proven in projects along busy roads such as the N9 near Alkmaar. With a design life of more than 100 years and minimal maintenance costs, it is a sustainable solution for aging infrastructure and definitely worth considering," Dick concludes.