Six megapumps for brand new pumping station on Afsluitdijk

Most exciting moment and ultimate test

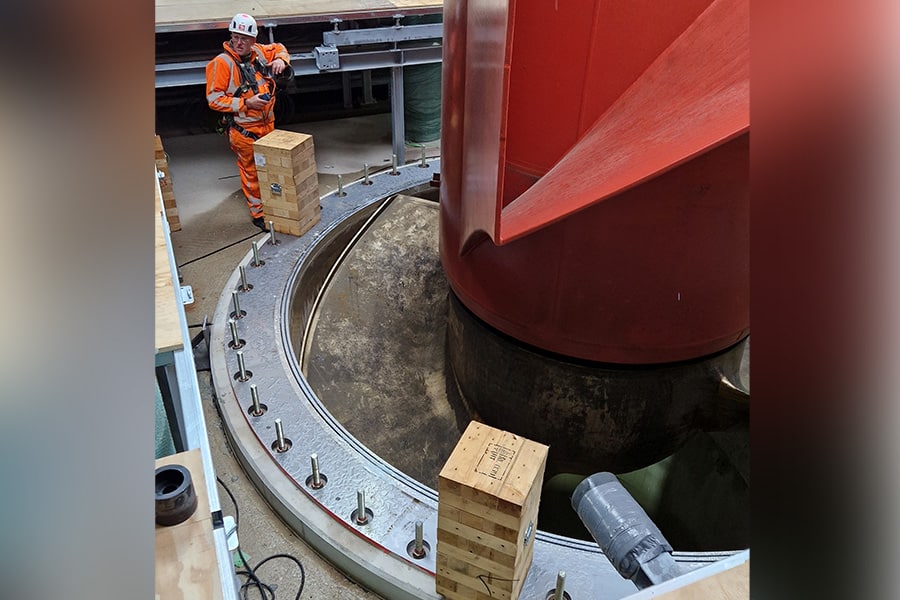

In May this year, the six giant pumps of the pumping station at Den Oever were installed. This pumping station is part of the reinforcement and renovation work being carried out on behalf of the Department of Public Works. Quite an operation considering the size of the pumps: 11.5 meters high and almost 5 meters in diameter. For Flowserve, responsible for the design and construction, this was the most exciting moment so far in the entire project. Because, says project manager Bert Waterink, "Installing the pumps was the ultimate test of whether we could deliver what we had promised."

The installation of the pumps in May went "miraculously" smoothly as far as Bert is concerned. "We spent a lot of time with the Levvel construction consortium (BAM, Van Oord, Rebel and Invesis) and Mammoet (a company that specializes in lifting and transporting heavy objects) on the preparations, especially for hoisting in the pumps, the motors, the couplings and everything related. Because in order to fit the pumps, there was only 8 millimeters of clearance all around. And that for pumps weighing about 90 tons each. So this had to be done with extreme precision. The preparation paid off, because in three weeks we were able to put all six pumps in place. A special moment for us when you consider that we spent years working on the order for the actual installation of the pumps."

Fish Safe

With as many as six pumps 11.5 meters high, the Den Oever pumping station is one of the largest pumping stations in Europe. For Flowserve, responsible for the development and production of the pumps, they are not only the largest vertical pumps they have made to date, but also the largest fish-friendly pumps. A solution with future prospects according to Jan Vervoort, sales engineer: "For almost all existing pump types for pumping stations, Flowserve has designed a fish-friendly solution. Moreover, many pumping stations are basically so good that converting existing pumps to a fish-friendly design is sufficient to make them future-proof. With a view to sustainability and reducing investment costs, a very interesting option for water boards."

Size has consequences

The size of the project made it quite a challenge for Flowserve's engineers and their colleagues who assembled the pumps. "Because of the size, a total diameter of almost 5 meters and a height of 11.5 meters, the basic design of our regular pumps is not sufficient," Bert says. "These pumps are as much as three times larger than we have developed so far. To put it mildly, then, a technical challenge, complex and anything but standard. The enormous size makes everything different. What materials will you use? How do you make sure the design is stiff enough that it won't deform? Where do you have a 33-ton impeller cast in one go? It has to be right on all sides, both technically and in terms of performance and aesthetics."

Back to the drawing board

However, at the time when the design was almost complete, it had to go back to the drawing board because of modified maintenance requirements. This had the necessary consequences for the internal part of the pump. Moreover, due to its size, it is too costly to remove the pump from the building in case of maintenance. Among other things, we modified the access to the pump, changed the lower bearing and modified certain dimensions. The pumps are accessible to maintenance personnel down to the bottom. We also created space at the bottom of the pump for people, such that they can perform maintenance ergonomically."

Exceptionally long

The project is an exceptionally long one as far as Jan is concerned. "In total, we have been working on it for about ten years. You don't experience that very often. As a Dutch company we are proud to have been able to work on this special project. In all those years there have certainly been perils, but we have always been able to secure a good and pleasant cooperation with Levvel."