'We all have a role in the transition to a circular economy'

"Whether you are consciously circular or not, nobody likes to throw things away, right?" Speaking is Onno Sminia, Innovation Manager at Croonwolter&dros. We speak to him about Croonwolter&dros' vision of circularity in infra. Circularity and sustainability are now so intertwined with the organization that they have become part of the corporate culture.

This enables Croonwolter&dros to act as a 'booster' when it comes to circular working. "We select our partners accordingly, and those who are not yet able to join in the story immediately, we stand by them. We all have a role in the transition to a circular economy and we can take the lead in this thanks to our experience and a strong drive to innovate."

Working smart and learning to think circularly

As a system integrator, Croonwolter&dros works with many parties who are also consciously concerned with sustainability and circularity. "There is always room for improvement when it comes to circularity. We have reached a point where not only we -and our partners- want to work circularly, now more and more clients are asking for circular and sustainable solutions. Where the will is there, the way arises. Particularly in the installation field, there is much to gain, as installations contain scarce components that come from all over the world. These components often make long journeys and are part of a long chain. Smart working and thinking differently help us in this regard. An example is reusing components that have been replaced in an installation by assessing them for their residual quality and reusing them as repair parts in another project, where the same hardware has been used. By giving parts a second life, we save a lot in terms of costs and CO2-emissions," Onno said.

Making material visible in the chain

For material to be reused in the chain, it must become visible. "So we are not only looking at the reusability of installations and components from installations, but want to reuse as many materials as possible in the chain. This is possible with the introduction of so-called materials passports in construction works. These document which materials are present within a structure, the quantities and, for example, the life cycle. Knowing what you have, makes you start using it, when you can." The first for the materials passport went to the A16 Rotterdam, the first tunnel in the world with a passport for materials and installations. "Thanks to such innovation pilots, we inspire others in turn," is Onno's opinion. "It's a kind of 'Tinder for materials.' A platform with supply and demand for materials that come out of the chain and can go back in."

Referring to the ten levels of circularity (the 10 R's - see box), Onno says, "The higher we get on the 10 R ladder, the more circular we are, that's our vision. In fact, circularity is not just about recycling or reuse. That's what a lot of people get stuck on in their minds. It's about the whole process, starting as early as design. The same applies to materials and energy in that respect. Think in advance. Indeed, by weaving it into your corporate culture, you know intuitively that something is good or not, That requires saying goodbye to old thinking on many fronts. Purchasing something more expensive, but extending lifespan? Do it! Then the advantage is not at the front, but at the back of the chain. Because there, too, it's going to make money in the end, but in a responsible way."

Modular construction

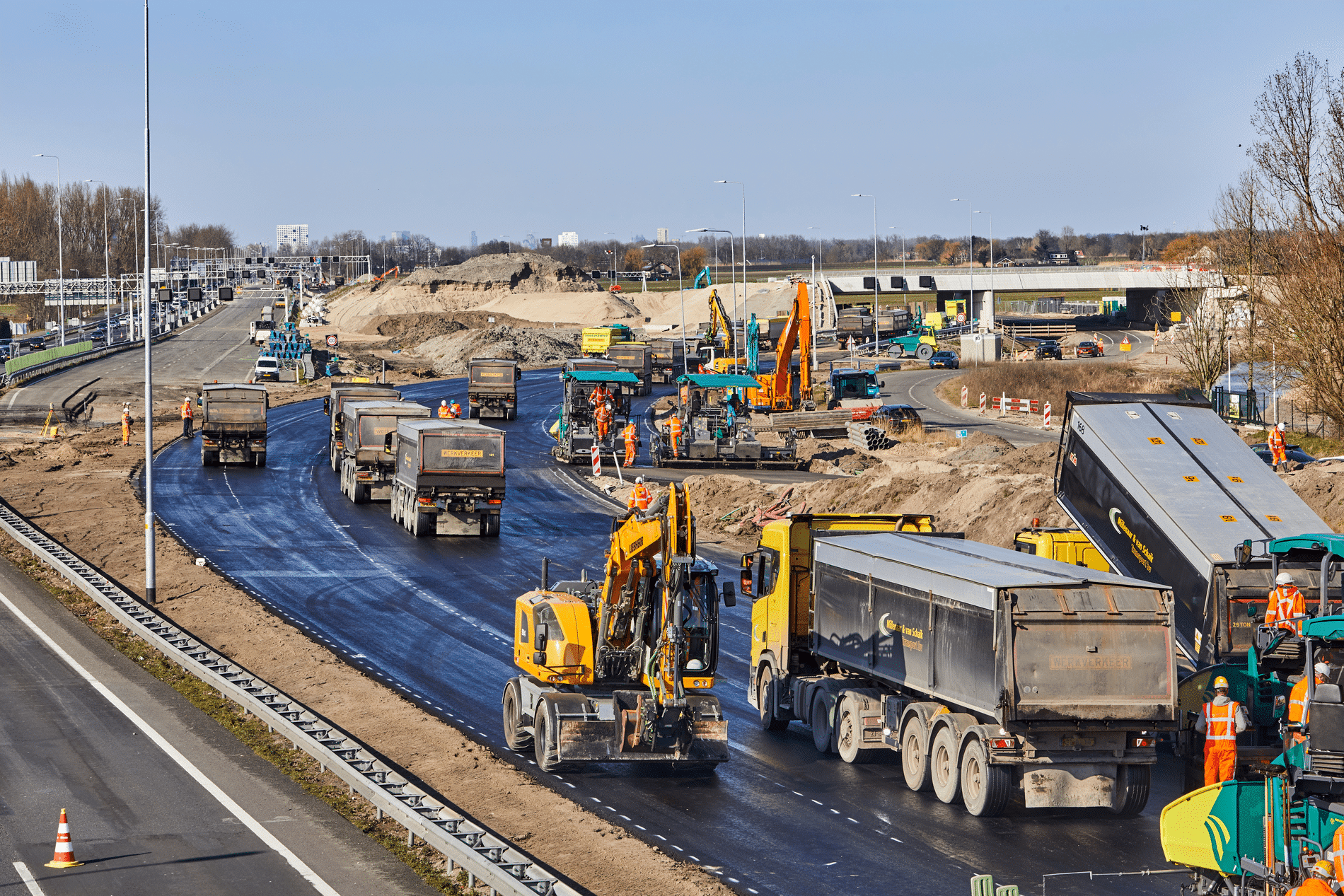

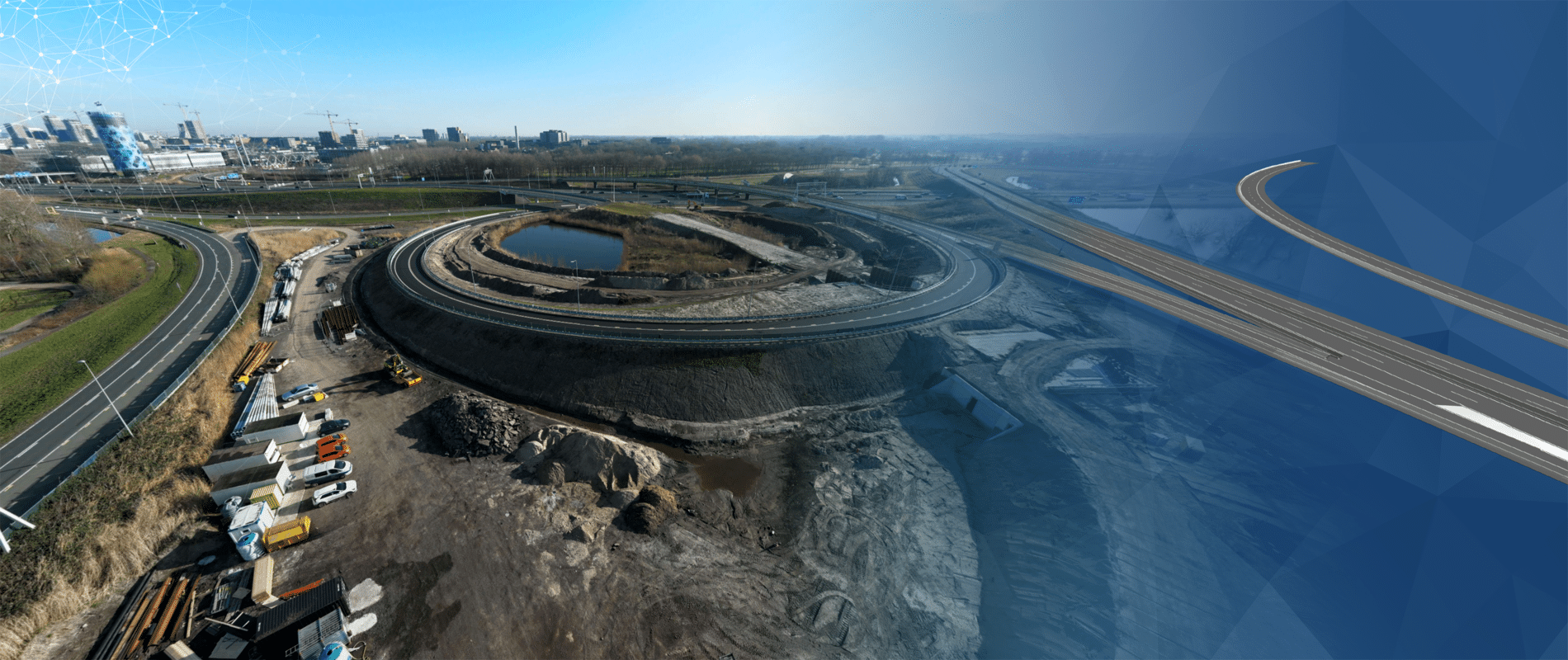

"Modular construction creates more opportunities in terms of circularity. Circularity becomes higher the moment something can be easily assembled and disassembled. As an example, I like to mention how the technical tunnel installations for the RijnlandRoute were prepared. All installations were assembled in Eindhoven, 'connected' and operational. This even allowed live testing. On demand, the various units went to their locations within the RijnlandRoute, to be connected plug&play."

Focus on energy and materials

"I feel that we are moving forward. However, we are working in the present and conforming to what is already possible, obviously trying to raise the bar a little higher each time for everyone," smiles Onno. "We do have to keep making progress. Of course, we don't have to cash in on our most extreme developments within a year, but we do want to see progress. With combined efforts, we are paving the way to take important innovations from drawing board to practice. This is only possible through cooperation. Cooperation within our company, cooperation in the chain."

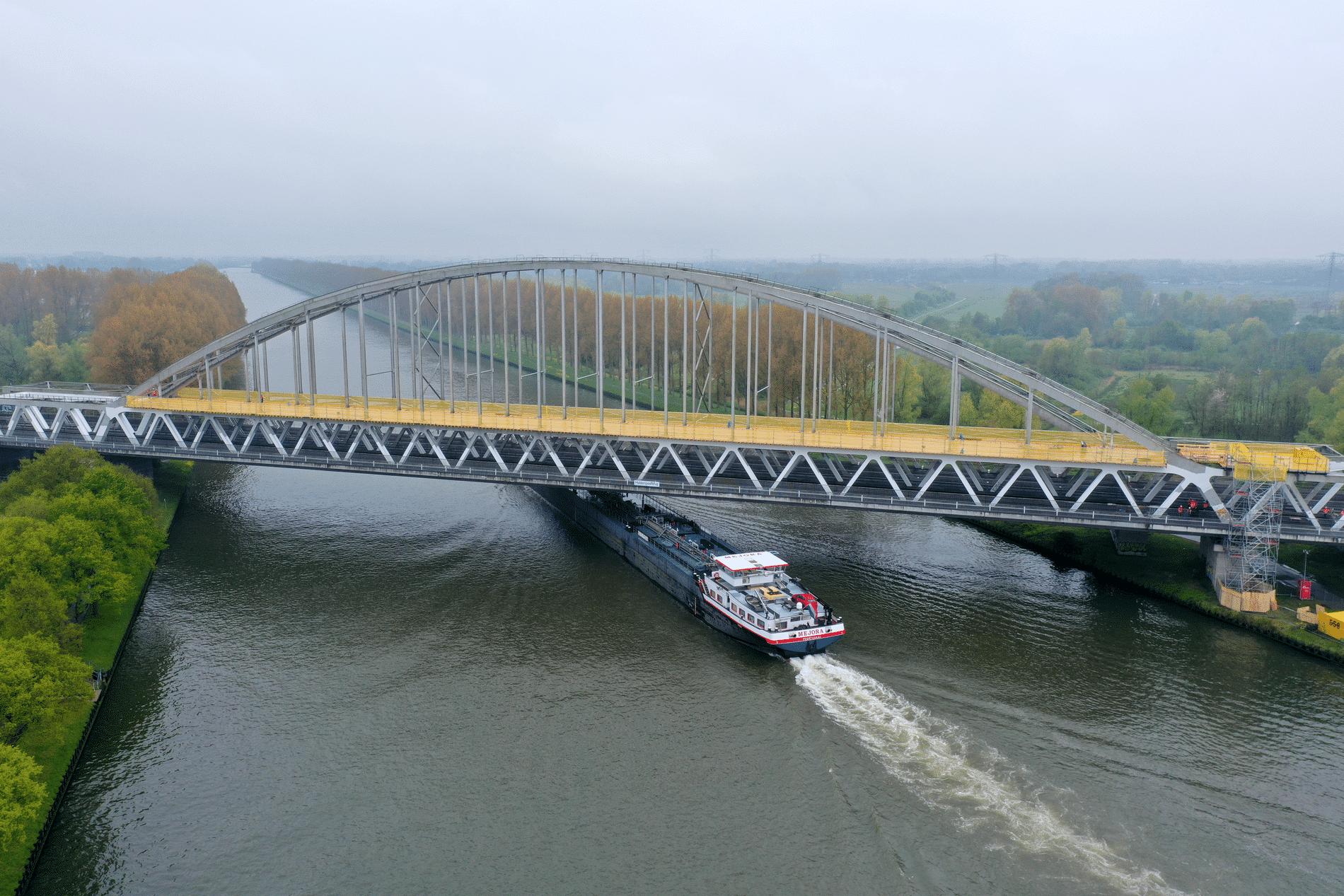

Anyone with good ideas is invited to include Croonwolter&dros in them. "Conversely, we also take parties on board; a good example is the project in which we are installing energy-efficient LED systems in the Westerschelde tunnel. Sustainable in itself, but we have agreed with the supplier of the fixtures that we want to create a plastic-free construction site. That requires a change in the logistical process on their part. If that willingness is there, you score together. We have a strong focus on energy and materials and our own roadmap is based on those two tracks. This is appreciated and taken up around us, as it is at Rijkswaterstaat. They deserve kudos because they too are increasingly facilitating innovations and increasingly entering into intensive partnerships to achieve sustainability goals. Innovative and constructive, in other words."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Croonwolter&dros.

Contact opnemen

Contact opnemen