Optimizing and making work processes more sustainable with innovative hardware and software

For many years, BAM Infra Nederland has relied on Geodirect's measuring equipment and software for road construction and maintenance. For the Vechtdal Link project, Geodirect's expertise was called upon to optimize and make the work processes involving positioning and geo-information more sustainable.

Vechtdalverbinding is a 40-kilometer stretch of road in the area between Zwolle and Hardenberg. There is a lot of (freight) traffic on this stretch every day. Especially during rush hour traffic jammed here. Reason for the province of Overijsel to tackle this stretch. In addition to improving traffic flow, safety and sustainability are being addressed in the largest infrastructure project in the province of Overijssel.

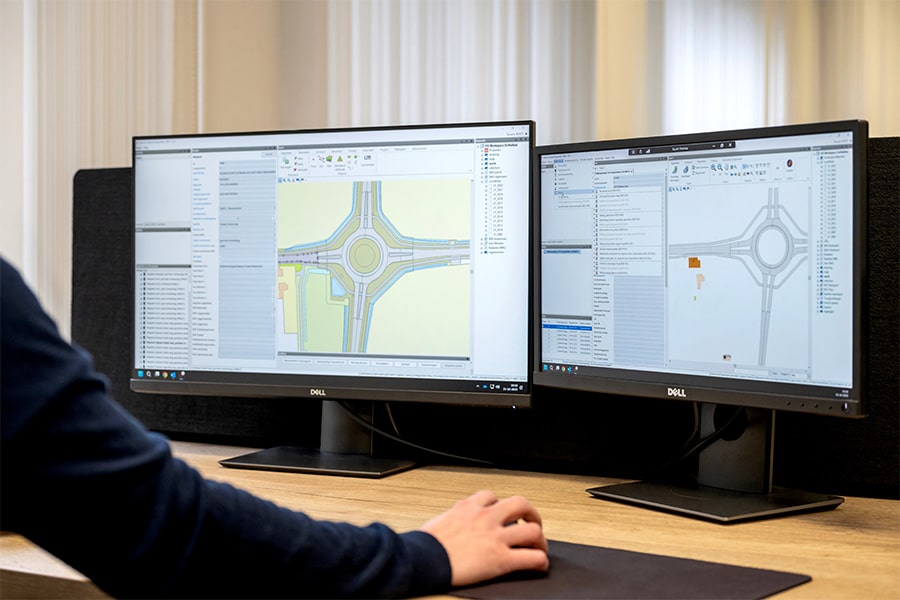

Innovative solutions and custom development

"The intensive cooperation with BAM Infra enables us time and again to develop innovative solutions that provide increased efficiency and cost reductions," says Jasper Zuidam, Sales Engineer at Geodirect. "For example, for the process of asphalt core drilling, survey and density measurements, we have equipped a drilling truck with the Stonex S900A RTK GNSS receiver for accurate recording of drilling locations. For recording sensor data and information, we combined the system with Geolantis.360 COLLECTOR. For the purpose of sharing information and flushing data into the various applications within the project organization, we developed a custom software interface."

Practical experience in the field

Superintendent Berthold Benneker of BAM Infra Asphalt is enthusiastic about the Stonex measurement systems, the Geolantis.360 platform and the cooperation with Geodirect. "I have been working with Geodirect's reliable Stonex measuring equipment and software for years. Once again, I have a fast and accurate system to work with. Ideal to have one system with which to do all the work."

"In drilling operations, we use the Stonex GNSS receiver to measure the asphalt cores and enter the asphalt composition into the Geolantis.360 app. In addition, when we raise sand and debris runway, we measure the locations, also knowing immediately in which runway section it is located. We combine the density measurements with a Troxler; we also record these measurements right at the measured point."

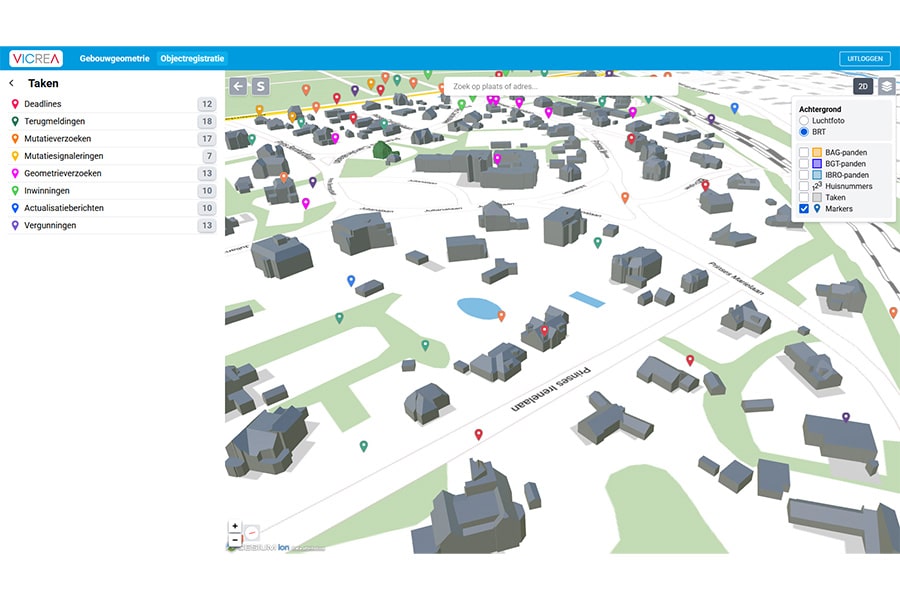

Setting up the work process

The digital work form in Geolantis.360 is set up with fixed data corresponding to the measurement, such as drill core, immobilizer, penetrograph, debris, stabilization sand, sand for embankment and sand for sand bed. After registration, the data are automatically synchronized and prepared using a custom-developed connector. The data is automatically specified by job section and exported to Excel documents. Work preparation always has real-time access to the data via the Geolantis.360 Cloud environment for further processing into delivery documents.

"The automatic synchronization saves an enormous amount of time," says Berthold. "We also no longer have to drive back and forth every time to bring data to the work preparation. Which is nice on a project as large as the Vecht Valley Link. We can do an awful lot with this system. And if we run into a technical problem, we can always count on the people from Geodirect's support department. They help us over the phone or look into the systems remotely to fix something immediately. Ideal when you're somewhere in the middle of nowhere."