A sneak preview of the smartest and most sustainable solutions in infrastructure

InfraTech Innovation Award 2025

Two years ago, then-Minister of Infrastructure and Water Management Mark Harbers presented the InfraTech Innovation Award. He then quoted Albert Einstein who once said that "logic gets you from A to B, but imagination can get you everywhere. According to Harbers, it is precisely the InfraTech Innovation Award that proves every two years that things can always be smarter and better. And so it is for the 2025 edition. Here's a sneak preview.

As in previous editions, the InfraTech Innovation Award 2025 is divided into three categories: product innovation, process innovation and sustainable forms of collaboration. This year, the jury received nearly fifty entries spread across the three categories.

Sustainable cooperation

What stands out in the sustainable collaboration category is that a large proportion of the innovations submitted are about reusing materials. The circular construction economy is thus getting a boost.

The Asphalt Recycling Train (ART) of Dura Vermeer, Art-E, Gelderland Province and the Department of Public Works recycles old asphalt directly on site. The ART is a series of maintenance machines that travel one after another in a train over a damaged road surface, leaving behind a nice, smooth, new coating. The first machines (pre-heaters) heat the road surface to loosen the asphalt. Next comes a remixer that loosens and eats the asphalt, processes it and reapplies it to the road surface. Finally, a roller comes and smoothes the road surface again.

BAM Infra submitted DuSpot. That's a matching tool for governments and contractors. It matches supply and demand for released building materials in different phases of a project. This should make it easier to reuse reusable building materials elsewhere.

And in the Buyer Group Grondstromen, public contracting authorities (Department of Public Works, municipalities, provinces and water boards) are developing a joint market vision and procurement strategy for the circular supply and disposal of soil. The Buyer Group Grondstromen aims to accelerate the transition to high-quality use of soil in projects of contracting authorities. This can be done by focusing on the physical, chemical and biological properties and values of soil.

Process Innovation

Within the Process Innovation category, it is notable how data and automation are gaining an increasingly prominent role within the maintenance and management of both above-ground and underground infrastructure. Rijkswaterstaat, for example, has now completed a number of successful pilots with data-driven asset management. Data-driven asset management gives Rijkswaterstaat the opportunity to get a better picture of the condition and lifespan of its assets, to manage them differently, to make maintenance predictable and thus more affordable. Rijkswaterstaat's Data-Driven Asset Management Program is ensuring the successful introduction of this way of working. Experience has been gained in a number of pilots for wet structures, movable bridges and tunnels, testing the management and maintenance using actual data, artificial intelligence and dashboarding at national and regional level. The key question here was: 'Does it work?'

The next period focuses on the "unification phase. In this phase, Rijkswaterstaat is creating the organizational, process and technical preconditions to do data-driven asset management throughout the organization for wet structures, movable bridges and tunnels. The key question in this phase is 'how do we as Rijkswaterstaat work with it?'

Antea Group goes one step further and even automates the design of rail tracks. RailDesign Pro is a tool that designs 3D models for the superstructure structure for both new construction and renovation of rail tracks and stabling areas, whether single or multiple tracks. Based on an alignment line, the RailDesign Pro generates a 3D model in Civil3D. The tool "reads" this line and then recognizes which track structure should be generated at which alignment sections. The designs generated by the tool fall within the framework of ProRail's design regulations. Designers do have room to make their own additional choices in the design.

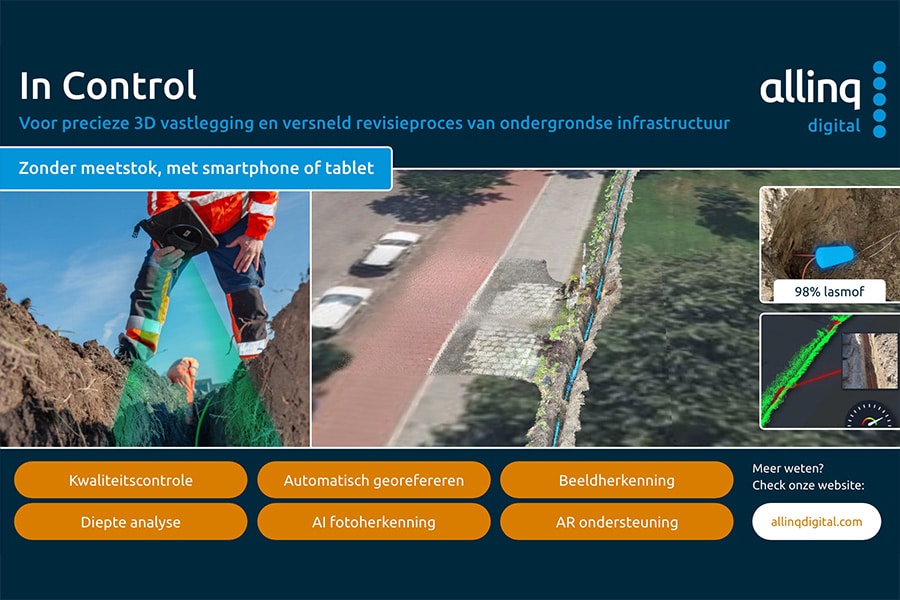

Allinq's 'In Control' innovation offers a solution to our increasingly crowded underground infrastructure. Allinq introduces a solution, which accurately records where and at what depth pipes have been laid. The excavation crew simply scans the area where the cable has been laid with a cell phone or tablet. The data is then processed into a 3D platform, or three-dimensional map. This digital measurement solution provides a wealth of information. By digitally measuring the trench, it is known exactly where the cables are and at what depth. The application uses a tablet equipped with LiDAR technology. This creates a three-dimensional point cloud, enabling accurate depth measurements and precise location determination. For example, excavation teams can add images to the point cloud and capture valuable visual information. The application stores this information, which can then be used for analysis and reporting.

Product Innovation

Traditionally, the Product Innovation category of the InfraTech Innovation Award has the most entries. These innovations include solutions as diverse as advanced technologies for water management, sustainable building materials, infrastructure inspection tools, and software solutions for project management and procurement. Each innovation focuses on improving sustainability, efficiency and safety within the infrastructure sector, such as innovative water drainage systems, circular materials, advanced inspection tools, and new techniques for energy management. The projects range from AR applications and modular building systems to eco-friendly stabilization technology and data-driven solutions for levee safety. The common thread in the innovations for 2025 is on sustainability, circular use of materials and improving efficiency and safety in infrastructure projects. They share a common vision of reducing the environmental footprint and creating smart infrastructure solutions that contribute to more sustainable management of public resources. We highlight some notable innovations that can help solve current challenges such as grid congestion, local road maintenance, climate adaptation, biodiversity restoration and circular building materials.

With smart precast girders, Mobriq halves construction time for foundations of high-voltage substations. The modular system Mobriq is a revolutionary way that combines speed and quality in switch fields of all types of power stations (110kV, 150kV, 220kV and 380kV). The system has been developed and successfully applied by Mobilis at TenneT in 380kV high voltage substation in Tilburg, 220kV Zevenhuizen and Bleiswijk and 110kV in Eibergen.

XenoBike is an innovative solution from the Belgian company XenomatiX, developed specifically for inspecting bike paths. It is a four-wheeled electric bike equipped with XenoTrack LiDAR technology and a complete 6D scanning package. This technology is designed to assess the condition of bike lanes, identify potential hazards such as cracks, holes and bumps, contributing to cost-effective maintenance. XenoBike uses LiDAR to create a detailed 3D model of the bike path, which is then used to identify maintenance needs and safety measures. The compact size of the XenoBike allows it to inspect hard-to-reach areas that are inaccessible to larger vehicles, such as narrow alleys or recreational trails. This helps ensure the safety and comfort of cyclists, as all potential obstacles such as tree roots, subsidence and other defects are detected and accurately located. The data collected can be easily integrated into Pavement Management Systems (PMS) and Geographic Information Systems (GIS), facilitating the planning and maintenance of bicycle paths.

Rolled dike liners, such as Naue Bentofix, are an innovative solution consisting of geosynthetic clay liners (GCLs) that can be easily rolled out for quick installation. Bentofix contains a layer of high-swelling sodium bentonite clay between two geotextile layers, providing a durable, self-closing seal. This technology provides effective protection against erosion and ensures levee stability by reducing water permeability and increasing structural strength.

Flax is a material we have used for thousands of years, in the form of clothing, bags, and ropes for ships. Recently, this ancient material has been "rediscovered," and could well become the building material of the future. The EU project 'Smart Circular Bridge' led by Eindhoven University of Technology recognizes this potential by building three city bridges from a biocomposite material consisting of flax and a special bio-resin. This material is light and very stable, with properties similar to aluminum or light steel.

The Smart Circular Bridge project is a consortium of 15 partners led by Eindhoven University of Technology. The project team includes five universities, seven innovative companies and three municipalities.

The first bridge was installed at the Floriade international horticultural exhibition in Almere in 2022. Two other "Smart Circular Bridges" for pedestrians and cyclists were built in Ulm- (Germany), and Bergen op Zoom, in 2022 and 2023, respectively. The intensive collaboration between science, business and local governments resulted in a multitude of innovations.

Many ponds, lakes, canals and ditches lack water structure; they are virtually barren. Young fish often find little protection in these waters, making them easy prey for predatory fish and cormorants. To improve fish stocks in these waters, fish forests are a great solution. The fish forest is a specialty of Van Aalsburg and consists of a double row of poles filled with willow branches. The fish forest can also be constructed with a grid of willow branches tied together with gaps of a few cm to, say, 40 cm. A fish forest can be applied in water depths from 50 to 300 cm deep. Cavities are created between these branches in which fish can hide. Small cavities mainly provide shelter for young fish, while larger fish can better hide between thicker branches and in larger cavities. Fish find plenty of food in and around fish forests. Furthermore, the forests serve as spawning grounds.

Minister hands out award

The jury of the InfraTech Innovation Award, consisting of Arno Visser (chairman of the jury and of Koninklijke Bouwend Nederland), Joop Polfliet (director of Public Works Stadsbeheer, Municipality of Rotterdam), Diana Beuting (chief engineer-director (HID), Rijkswaterstaat), Marcel Hertogh (professor TU Delft and Erasmus University Rotterdam), ir. D'tasha Demmerer (project engineer hydraulic engineering structures, Witteveen+Bos and board member Young NLingenieurs) and Doekle Terpstra (chairman Techniek Nederland), will consider all entries in the coming weeks and then decide which nine innovations (three per category) will be allowed to make a presentation in December. On January 15, 2025, the winners will be announced by the Minister of Infrastructure and Public Works, Barry Madlener. He will hand out the awards starting at 11 a.m. in the pavilion of Rijkswaterstaat.

With over 450 exhibitors and more than 200 knowledge sessions, InfraTech 2025 offers plenty of networking opportunities and inspiration. Register now for free access via www.infratech.nl