Circularity in infra not only sustainable but also money-saving

Croonwolter&dros has been involved in the Westerschelde Tunnel since 1989. The first 10 years for the design and construction and maintenance of the Tunnel Technical Installations on behalf of the Middelplaat Westerschelde Combination. And from 2013 as part of the Westerschelde Tunnel Maintenance consortium, consisting of Croonwolter&dros, BAM and Mobilis who are carrying out the new maintenance contract.

Preventive replacement of the HF system

Speaking is Martijn Bastiaanse, Project Manager at Croonwolter&dros and responsible for the Westerscheldetunnel project: "The contract runs for 20 years. The tender included a renovation of the Tunnel Technical Installations (TTI), which took place in 2017-2018. Research showed that the High Frequency installation in the tunnel could no longer be maintained for 30 years. Siemens, the supplier of the HF installation, had ceased production of parts. However, according to the contract, the installation must operate reliably throughout the maintenance period. Reason for us to replace this HF installation, which provides all communication in the tunnel (radio, telecom and C2000). Meanwhile, a new See-Telecom HF installation, supplied by Koning & Hartman, has been commissioned. The old radiating coax has been reused."

With the redeployment of parts, repairs and maintenance can now be carried out so that the HF systems continue to function optimally in accordance with requirements.

Three hundred and thirteen components came as called for elsewhere

Renze Zijlstra, Product Manager GSM-R/C2000 for High-Frequency installations at ProRail, is very pleased with the Siemens components that came out of the Westerschelde Tunnel. "ProRail acquired 313 electronic Siemens components from Westerschelde Maintenance. ProRail also uses this equipment from Siemens, it is the basis of the GSM-R and C2000 communication system in as many as 18 train tunnels. The system is so stable and reliable that I preferred to extend the life of the equipment in the train tunnels rather than start replacing everything. To that end, I then started a search for parts," Zijlstra said.

ProRail found the materials it was looking for at the Westerschelde Tunnel, among other places. "Because it was a preventive replacement there, everything was still in fine working condition. The parts were refurbished and stocked by our management parties. We can now use them to perform repairs and maintenance so that the HF installations continue to function optimally in accordance with requirements. We also use the components to adapt the current installations to ensure continuity of service.

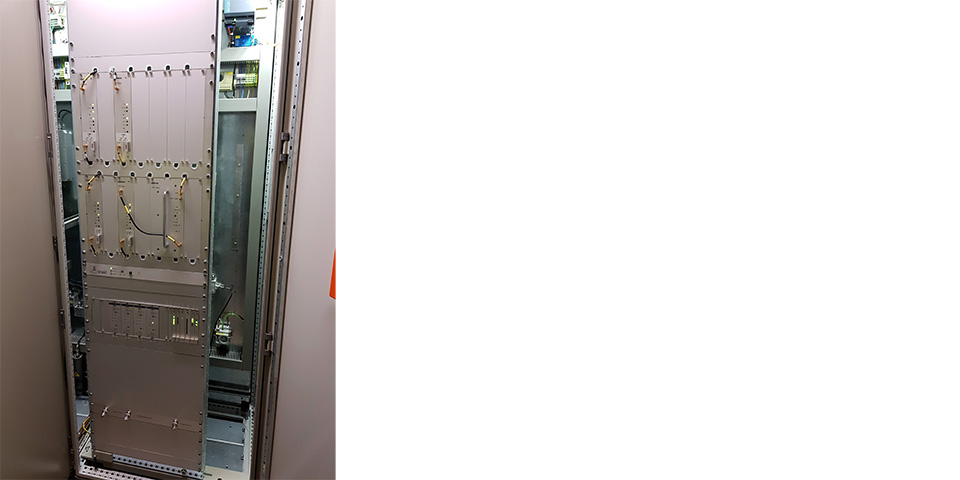

HF installation at canopy Rijswijk (rail) with components modified by reusing components from the Westerschelde Tunnel, among others.

Smart configuration changes also provide additional savings

"The components give off an enormous amount of heat," Zijlstra continued. "By applying smart configuration changes, we are able to lower the temperature by 10˚ and halve the required power supply. That works to prolong service life and also provides a total savings of 64,000 kWh on an annual basis."

Another beneficial effect that occurs is that lower temperatures reduce the need for forced cooling inside. "Another nice saving. To be sustainably innovative in such a way takes guts," Zijlstra outlines. "However, we managed to convince the management quite well. By now, 8 of the 18 tunnels have been modified."

Research showed that the High Frequency installation in the Westerschelde Tunnel could not be maintained for another 30 years.

Working Circularly in the GWW

Guido Koopmans, Project Manager and person with final responsibility at Westerschelde Maintenance, talks about the circular idea that has long been present at Croonwolter&dros: "The focus within GWW is on asphalt and concrete, when people talk about sustainability. In installation engineering it is less obvious, but the misconception exists that sustainable means paying extra money. Nothing could be further from the truth, circular thinking can pay off across the board. Within the life-safety-availability triangle, you have to weigh up whether to replace everything, partially replace everything and when to replace everything. Our long-term goal is to avoid destruction of resources and waste of energy. Surely the 'Quick win' with regard to circularity in our business is to look at extending the lifespan of installations."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Croonwolter&dros.

Contact opnemen

Contact opnemen