Revolutionary developments in concrete reinforcement

Whereas until recently rebar was the means of increasing the strength of concrete, it now appears that the same result can be achieved with plastic fibers. The advantages are great. Plastic fibers are significantly cheaper than steel and - besides being strong - also make the concrete durable and innovative.

A leading company in this field is FORTA Corporation USA. The innovative company brought together different synthetic fibers, bundled them in a specific way and, in doing so, had a revolutionary reinforcement material on its hands. It gave it the name "Forta-Ferro," which means "as strong as steel. Forta-Ferro is proving to be the perfect alternative to reinforcing steel while also greatly reducing building construction costs.

Twisted bundle structure

Forta-Ferro Fibre is a macro/structural color-mixed synthetic fiber made from "copolymer," also known as "polypropylene. The material consists of an intertwined mixture of non-fibrillating monofilaments and fibrillating network fibers, giving it high tensile strength. Within the twisted bundle structure, all materials have their own task. For example, the monofilament provides protection and the mesh polypropylene fibers prevent the material from breaking. With this, Forta-Ferro has all the qualities to replace reinforcing steel for reinforcing concrete where it can.

Structure strengthening

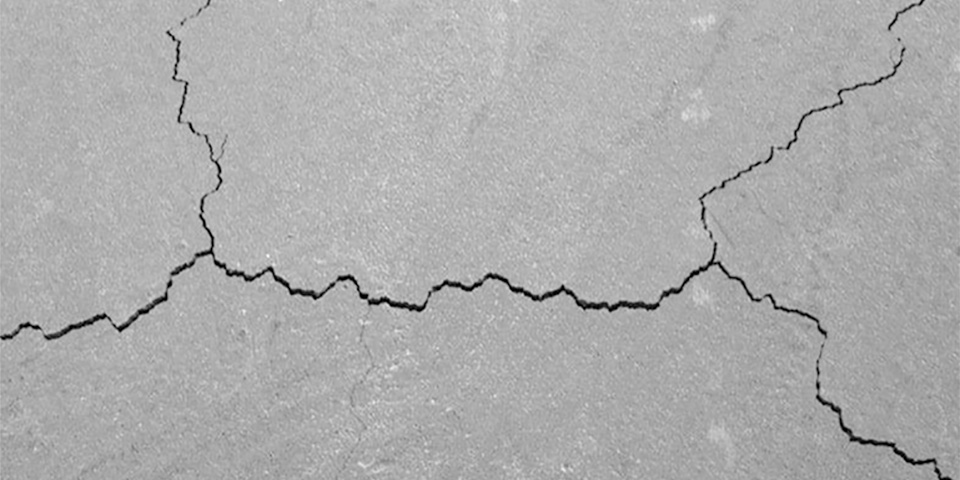

"The material offers revolutionary advantages," says Henk Hilverink of Dutch Fiber Trading. "Forta-Ferro fibers were already being used to reduce shrinkage in plastic. Now this quality is being used to prevent shrinkage cracks in concrete. Forta-Ferro makes concrete strong. In the process, the material is non-corrosive, extending the service life of concrete structures. And thanks to the three-dimensional coverage of the reinforcement, it strengthens the structure of the concrete from the inside out."

User-friendly

The plastic reinforcement increases the tensile strength of the concrete, enabling it to withstand heavy loads. The material can be produced with minimal manpower. It can be delivered in shorter time. It can be dosed in multiple ways in the concrete plant and in the mobile mixer on site. The fibers are non-magnetic and, finally, user-friendly. With these high qualities, Forta-Ferro guarantees great savings in the construction industry.

Proven results

To prove the strength of Forta-Ferro, precast structures were subjected to extremely heavy loads using vacuum tests. These tests showed that Forta-Ferro fibers work extremely well for precast structures. Not surprisingly, Forta-Ferro is increasingly chosen as a reinforcing material for septic tanks, manholes, industrial floors, the agricultural sector and other precast elements. In these applications, too, Forta-Ferro provides substantial savings.

Application

More and more we see Forta-Ferro fibers finding their way into utility construction. Here, too, the application of the material reduces reinforcing steel.

Examples include the reinforcement of bridge decks, commercial and industrial floors, concrete roads, bicycle paths (White Topping), airports, service areas, linear structures and public transportation. We see Forta-Ferro advancing in sprayed concrete work such as swimming pools, ramps, tunnel linings, rock walls and waterscapes.

Dutch Fiber Trading is exclusive distributor and stockholder for the Benelux and Netherlands Antilles, also providing design and calculation for projects free of charge.