JCB keeps making it easier for operators

At the press days held in mid-March, JCB showed not only new machines, such as the powerful 370X crawler excavator, but more importantly all kinds of improvements that will benefit operators. This starts in the cab of the 370X. The new JCB UX interface has up to 25 user profiles. These all offer the possibility, for example, to set the joystick configuration according to personal wishes and requirements.

The 35-40-ton 370X is the largest and most powerful tracked excavator in the British machine manufacturer's X Series. It comes with a 6.45 m monog boom and a choice of 2.63 m, 3.23 m and 4.03 m dippers. Under the hood we find the latest EU Stage V Cummins L9 diesel engine. This 8.9-liter six-cylinder engine offers a power increase of 14% over the previous JS370. Power of 240 kW (322 hp) is delivered at just 1,700 rpm. Longer service intervals should ensure lower total cost of ownership (TCO).

Increased hydraulic pressure helps make it possible to move 4.5 tons more material per gallon of fuel than competing models, according to JCB. The improved undercarriage and extra-heavy counterweight provide maximum stability.

UX interface improves user experience

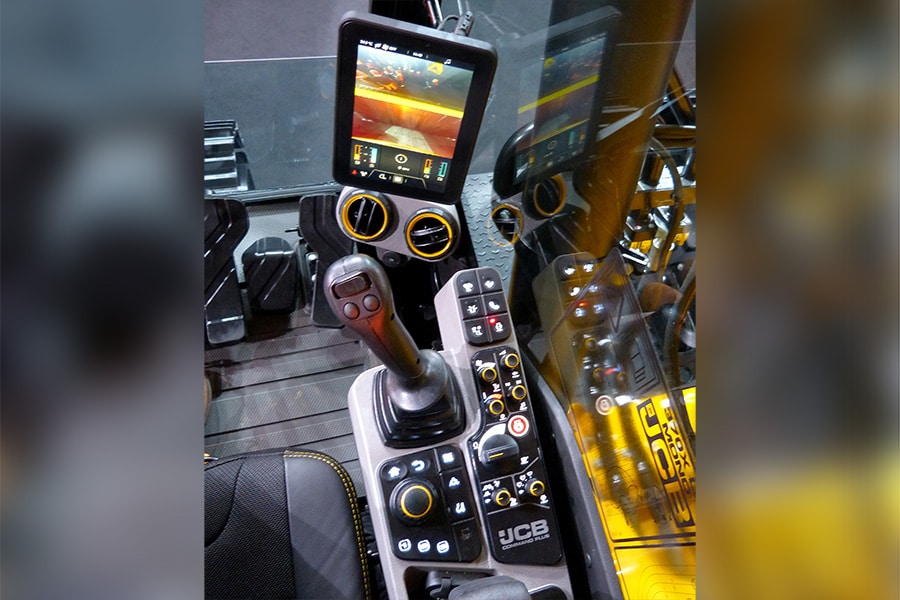

JCB has revamped the interior of the cab for its X-Series excavators. The results are first to be experienced on the 370X: a large 10-inch touchscreen, a quick menu on the six-button pad; keyless start, an improved rotary knob and best of all, an easy-to-use system that allows operators to customize control levers and various functions. We already mentioned those up to 25 user profiles. Each operator can define for himself how he wants to work. He can preset hot keys, including the buttons in the joystick levers and three hot keys on the switch panel. He can also save the settings of 15 frequently used attachments in the menu, making them quickly retrievable. Conveniently, the quick coupler can be unlocked without pressure on the attachment.

Not everything is digital: for ease of use, there are still physical knobs for cabinet temperature, fan speed and volume control (also adjustable via the touchscreen). Engine speed is controlled by a physical dial with throttle settings from 1 to 9+, in addition to three operating modes (Power, Eco and Lifting).

Those who find it all a bit uncomfortable at first can take advantage of help guides and instructional videos on the touchscreen. Integration of the phone book has also greatly improved connectivity for cell phones.

Semi-automatic machine control

JCB and Leica Geosystems will jointly offer factory-mounted 2D and 3D-ready semi-automatic machine control. This INTELLIGRADE will initially be available on the JCB 220X crawler excavator. After a successful trial period, the system will become available for all JCB X-Series machines. By fitting the system already at the factory, it is already properly set up and ready to use. Machine operators can therefore use all the benefits of INTELLIGRADE without the complexity of retrofits in the field.

New Hydradig versions

JCB will broaden the offering of the successful Hydradig wheel excavator with the Hydradig Plus and the Hydradig Pro. The Plus version is expected to be the most popular model, with a tailored mix of specifications. The excavator comes standard with boom suspension (SRS), single-point axle lubrication, reverse steering and two low-flow auxiliary lines. Also included are a deluxe air-suspension seat, Bluetooth radio, LED work lights and fuel pump.

The Hydradig Pro will be the top model with maximum versatility. Optional features include a drawbar and high-flow hydraulics. This allows the Hydradig Pro to work with the widest choice of mechanical and powered attachments. It also becomes possible to quickly switch between setups, increasing both uptime and productivity.

JCB Raptor for Hydradig

Nice news is the JCB Raptor. That's a brand new tiltrotator designed specifically for the JCB Hydradig. With its 460 mm width, it provides better visibility and control from the cab. At 2.9 kNm, it has the best tipping torque in its class. Furthermore, it has a 120 liter/min high flow through the center, allowing 360-degree rotation for flow demanding attachments. The JCB Raptor offers a tilt angle of up to 45 degrees and a rotation speed of up to 8.5 rpm. Maximum breakout torque is 67 kNm and rotational torque is up to 5.4 kNm. The tilt rotator can be mounted directly on the dipper or on an S45 or S50 quick change.

And further, we saw:

That JCB has expanded its range of electric dumpers with the 3TE, an electric dumper with 3,000 kg payload and two electric motors: one for the permanent all-wheel drive and the other for the all-steel tipping bucket with rotating tip to allow loading and unloading in tight, confined spaces. It has a 20 kWh lithium-ion battery pack, which guarantees a full working day in normal operation.

Other news are the two 2.5-ton mini-excavators. The 25Z-1 is a zero tail model that replaces the 8025 ZTS, while the 26C-1 with its conventional counterweight is the replacement for the 8026 CTS.

The range of tandem vibratory rollers under 5 tons has been expanded with the CT380-130 and CT430-140. Both rollers have a Stage V diesel engine from Kohler and offset capability for precise (cornering) work. Automatic vibration control (AVC) prevents excessive compaction on end pieces.

Finally, JCB presented the updated excavator loader combination with dual drive ex-factory. More than 70 years after the introduction of the Mk 1 Excavator, the operator no longer has to look over his shoulder, but can turn his seat in a factory machine in the direction of his work area: bucket or backhoe.