Welding at the very highest level

And sustainable too

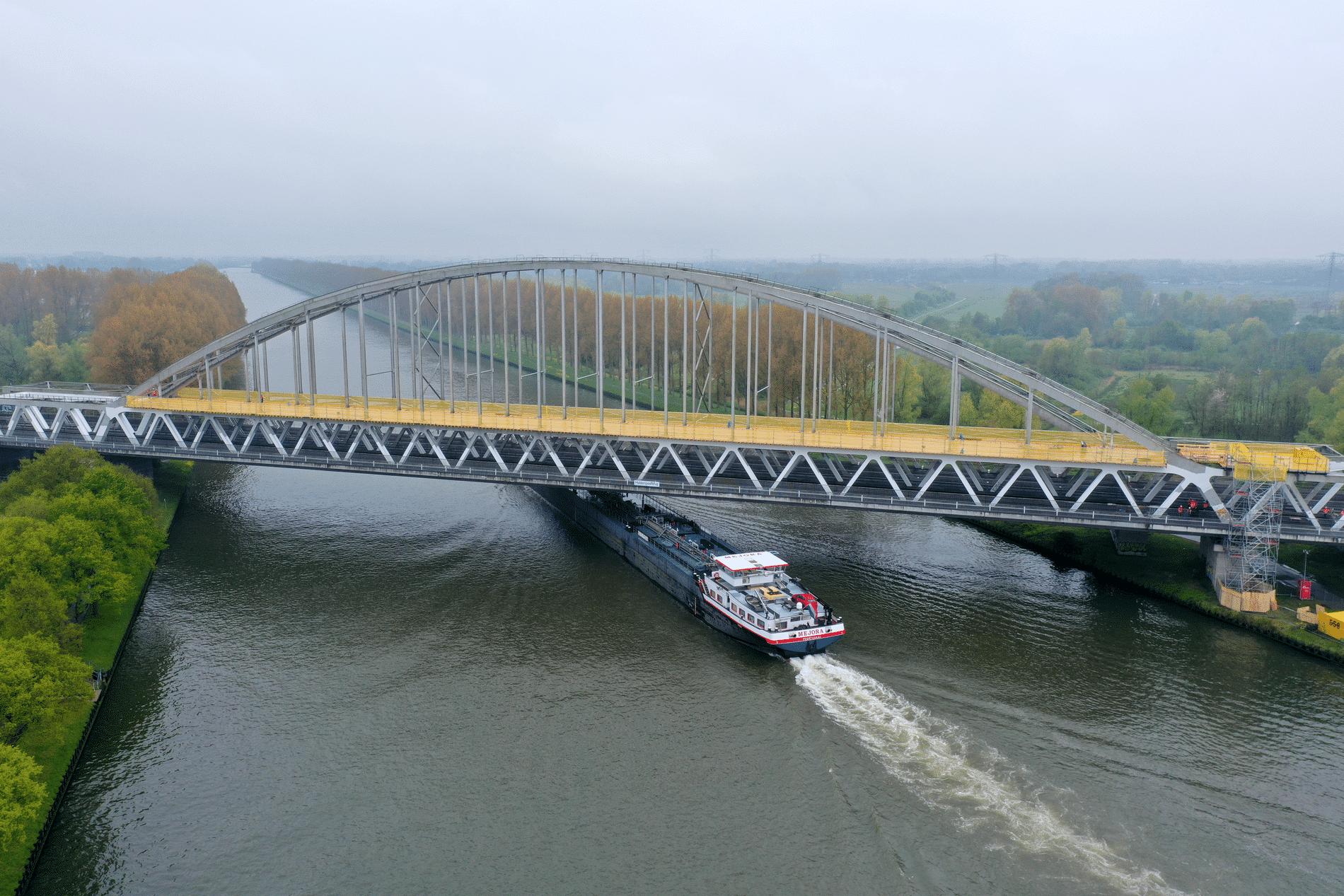

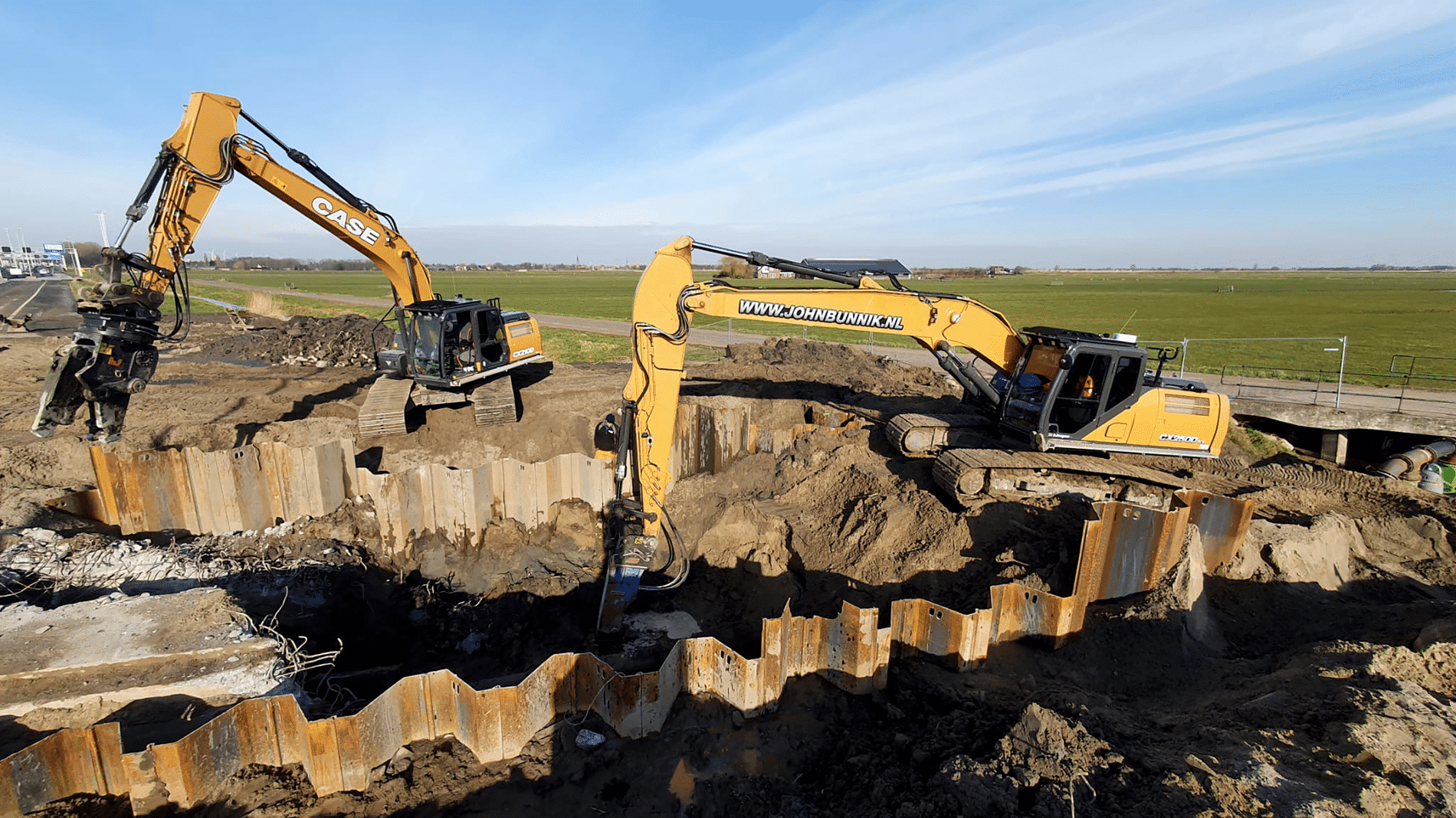

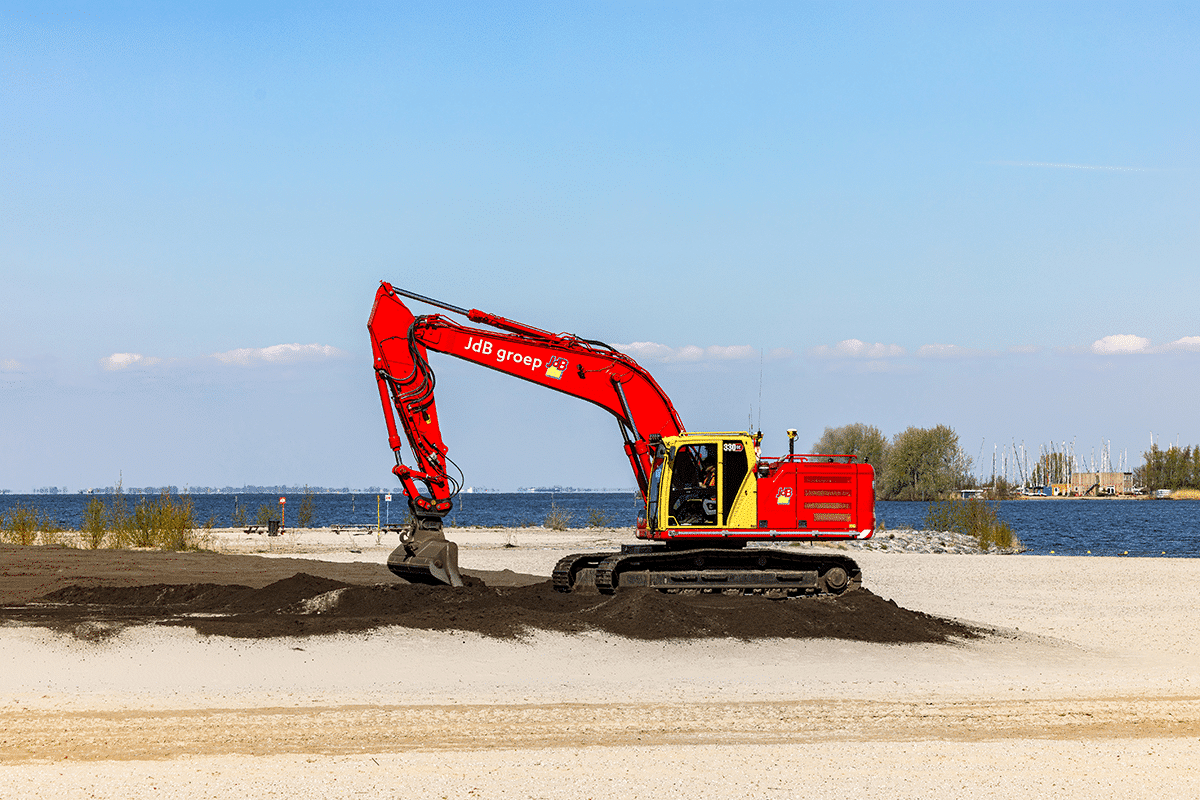

Lommers Welding Services is a well-known name in GWW. Many an infrastructure contractor calls on the expertise of the family business, which is often involved in the preliminary phase for testing and checking the feasibility in cooperation with its partner Kok en van den Heuvel. "Based on the design, we make the welding plan and provide the welding method descriptions," says director Gerda Lommers. "If demanded, we weld under, for example, the highest execution classes 3 and 4 and the ROK." And preferably, this is done in the most sustainable way possible, because Lommers Welding Services has recently provided a solution for that as well.

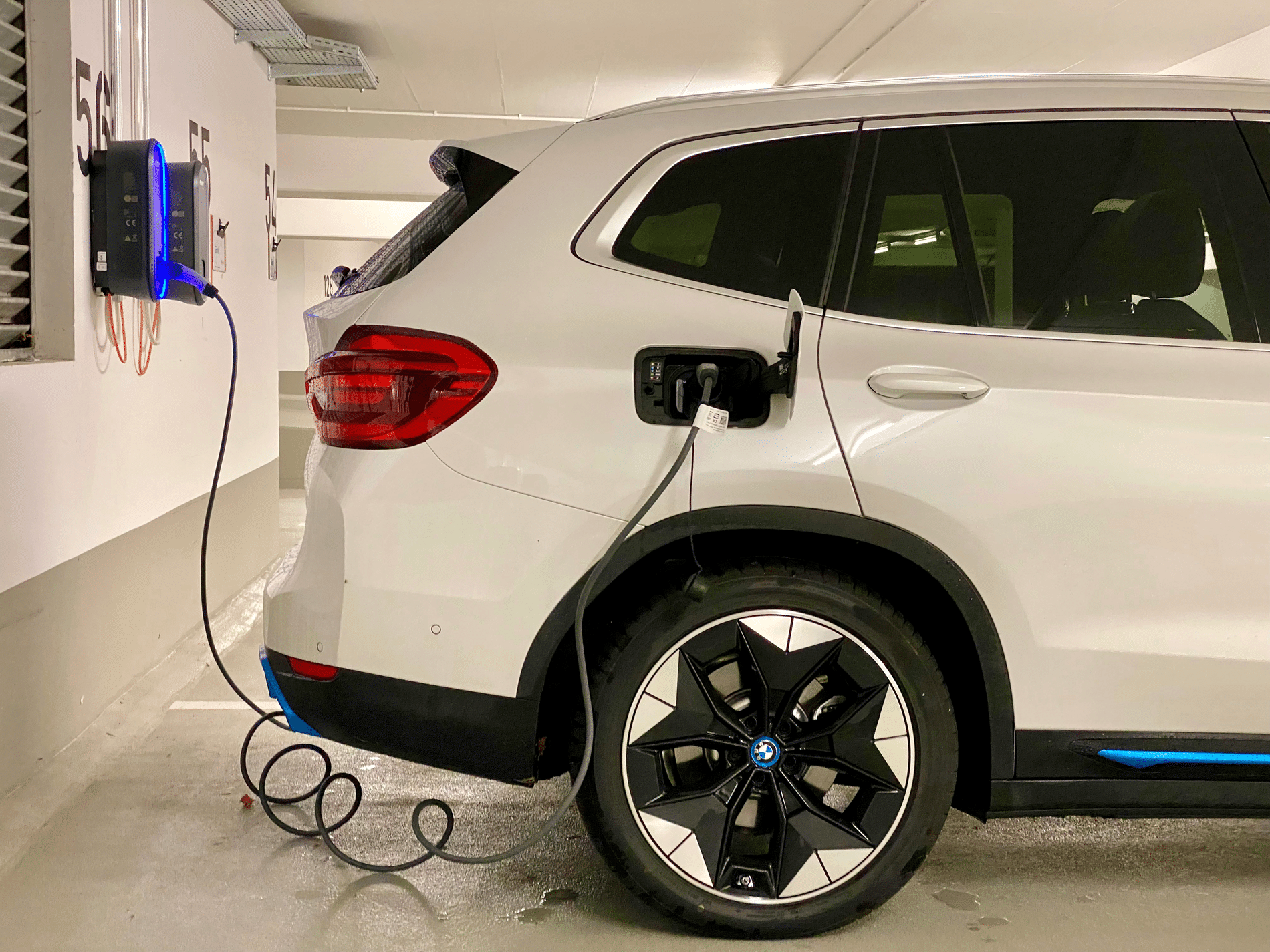

The construction and infrastructure sector has quite a challenge to reduce emissions and eventually go zero-emission, Gerda rightly states. "That also applies to our operations. After all, a welding machine draws quite a lot of electricity. Nevertheless, we are constantly working to reduce our carbon footprint. For example, we drive partially electric and recently we also started to have a solution to supply our equipment with green electricity on location. For this, we have partnered with EcarPower, manufacturer of clean energy solutions based on second life car batteries."

Different gradations

EcarPower takes in batteries no longer suitable for automotive use and thus builds energy storage systems of various degrees. The concept that Lommers Welding Services makes grateful use of is the mobile trailer with a battery of 45 kVA and 50 kWh. "The power is relatively limited compared to what is consumed on an average construction site, but it offers enough power to power a welding machine for a day, for example, or to smooth out peaks," explains Nick Lommers of EcarPower. Gerda says the mobile energy storage makes them completely self-sufficient and extremely sustainable on smaller jobs. "Because with an electric car we can also get by in any city center/parking garages."

Extensively certified

In urban locations, Lommers is increasingly using welding containers. "These ready-made units make us completely self-sufficient. Thus, we no longer need a heavy work bus for work in zero-emission zones, and we can drive up and down with electric vehicles. Both the cars and the battery are charged with green electricity." So in terms of sustainable deployment, Lommers Welding Services is leading the way, but also when it comes to certification and welding method qualifications. "By continuously working on all quality requirements of the NEN-EN 1090, both in the workshop and on assembly, we deliver demonstrable quality. Moreover, for higher execution classes, a certified welding coordinator level C (IWE) is always available." Thus, no challenge is too big for the welding company.

In the most recent versions of both the NEN-EN 1090 and the ROK (Guideline for the Design of Art Works) requirements are set for the quality of all welded joints including reinforcement steel as well as ordinary structural steel. For this, Lommers has obtained welding method qualifications for the most common diameters and welded joints. "A number of welders have also been trained specifically for welding to reinforcing steel, as a result of which we have achieved ISO 17660-1 certification," Gerda explains. "To achieve that, you have to meet strict audits. So it's a real seal of quality for welding to rebar."