Renovation, strengthening and expansion of Schiphol Bridge A9.

Work on the Schiphol Bridge in the A9 motorway is in full swing. The project is being carried out on behalf of Rijkswaterstaat (the Directorate-General for Public Works and Water Management) and is rightly called a technical tour de force. It is a gigantic infrastructure project. When the bridge is finished, it will be the widest bascule bridge in the Netherlands. But what is actually changing about the bridge?

The Schiphol Bridge is an important structure in the A9, facilitating the junction between the A9, the Nieuwemeerdijk N231, the Ringvaart and the Schipholdijk. It consists of two bridges (north and south) with two movable steel traps with electromechanical motion mechanisms. The renovation and expansion include widening of the concrete decks and substructure, renovation of the bascule basement and construction of a new control building. This bridge construction requires careful design, planning, construction methods and phasing to create a safe, efficient and durable bridge that meets growing traffic demand with a 30-year residual life.

Steel decks

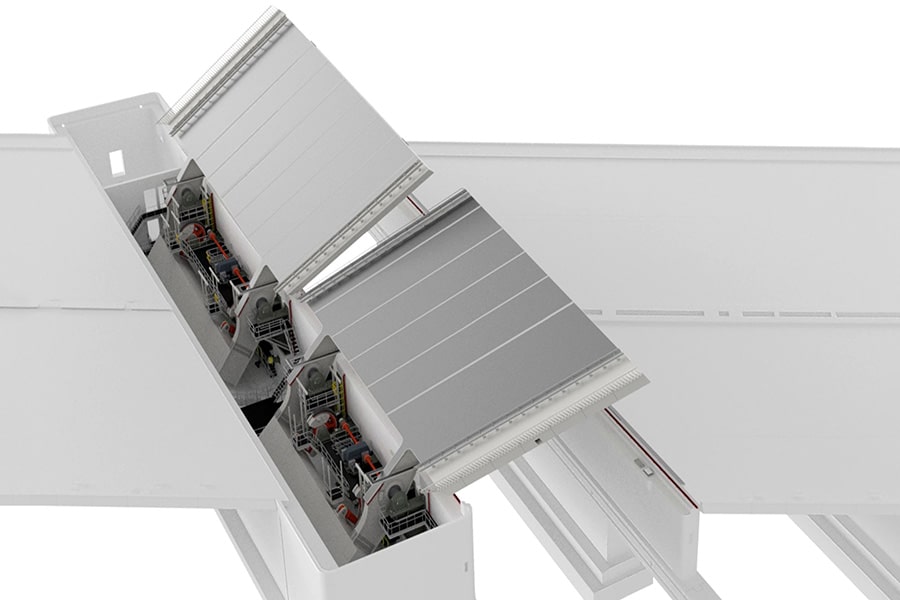

The Schiphol Bridge consists of two sections, one for each direction of travel. Each bridge is divided into a western approach bridge of about 85 meters long, an eastern approach bridge of about 165 meters long and a movable section of about 20 meters span.

For the new situation, the two existing steel traps and drive will be completely replaced and widened on both sides. The movable part of the bridge consists of an orthotropic driving deck supported by cross girders and main girders. The steel traps of both bridges (north deck and south deck) are nearly identical in design and detailing, except in width, due to the number of lanes they must facilitate. The north deck is significantly wider than the south movable deck.

For the northern bridge, the ballast box will be filled with a total fixed ballast of about 442 tons. The design of the ballast box of the southern bridge differs slightly from the northern bridge. The ballast box of the southern bridge, which has a smaller width, is filled with about 362 tons of solid ballast.

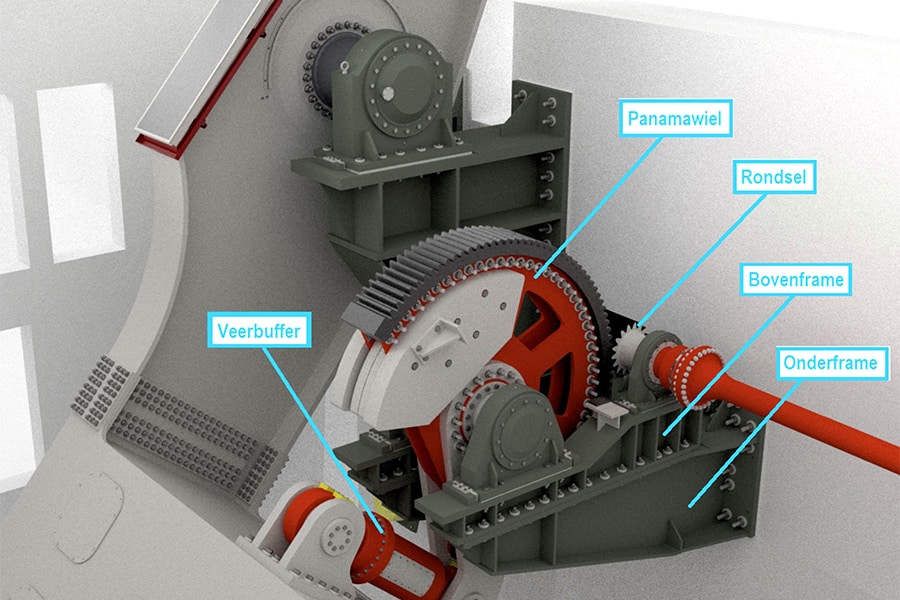

Mechanical equipment

The mechanical equipment of the Schiphol Bridge is vital to the reliable and available operation of the bridge. It includes various components and systems that work together to ensure the movement, safety and maintainability of the bridge.

One of the most important aspects of the mechanical equipment is the bridge motion mechanism. This electromechanical motion mechanism allows the bridges to open and close independently for the passage of ships. It includes a robust drive system, with electric motors and gear mechanisms (panama wheel pinion drive with crank drive rod), which ensure the powerful and precise movement of the movable bridge sections.

In addition, the mechanical equipment includes a crank drive rod mechanism that provides a set-up force (the "locking and securing of the bridge") for the purpose of guaranteed closed location. This contributes to the safety of the bridge and minimizes the risk of failure.

Sensors and measurement systems are also being integrated into the mechanical equipment. Among other things, these sensors monitor the position, speed and forces applied to the bridge. They provide the control and monitoring system with valuable information, making it possible to accurately position and monitor the bridge for possible deviations during the opening and closing cycles. Based on this data, timely maintenance can be performed to ensure the optimal operation of the bridge.

In addition to the above systems, other mechanical components such as bearings, seals and emergency drive are also present, and both traps are equipped with a manual drive. These components all play a crucial role in the smooth operation of the bridge and must be regularly inspected and maintained to ensure optimal performance.

To maintain the bridge in the open position, a locking device is provided in the bascule basement in case parts of the actuator need to be serviced or replaced.

Concrete decks

An important aspect of the renovation and expansion of the Schiphol Bridge is the widening of the existing concrete decks, which are post-tensioned in the work. In order to accommodate the increased capacity requirements (road widening), the existing concrete decks will be widened and an advanced coupling between the existing and the new deck will be created. This is achieved by creating an integrated system of reinforcement to be drilled into the existing concrete decks and free blasting reinforcement to lay ancillary reinforcement. This coupling ensures that the forces exerted on the bridge are evenly distributed throughout the bridge deck. This ensures strength, stability and safety and creates a functionally wider driving deck to facilitate the widening.

Bascule Basement

The bascule basement is an essential part of the Schiphol Bridge. It plays a crucial role in the opening and closing of the movable parts of the bridge. The basement houses the mechanical equipment. It also provides the necessary strength, stability and force induction during the movement process of the actuator, which introduces considerable forces on the concrete structures and foundation.

The existing bascule basement will be renovated and modified to meet the requirements of the new bridge configuration. Several modifications will be made, such as replacing the joint transitions, renewing the basement roof and reinforcing the walls and floor. The front wall will also be completely demolished and rebuilt to a height of about 0.5 meters above sea level. This renovation work will ensure that the basement can withstand the increased loads and force effects and continue to meet structural safety standards with the intended residual life of 30 years. To accommodate the new configuration of the bridge (road widening), the bascule basement will be expanded on the north and south sides.

Operation Building

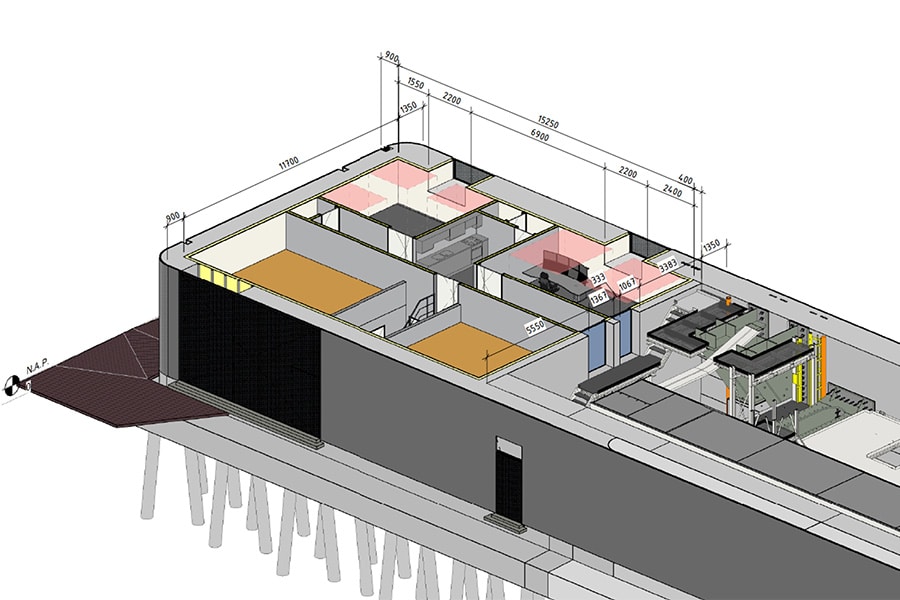

A new control building will be built on the north side of the Schiphol Bridge. The existing control tower will be completely demolished. The new control building will be realized as a box-in-box construction. The control building is designed to provide a safe and comfortable working environment for the personnel operating the bridge. Although hidden from direct view from road traffic, the control building is architecturally designed and incorporated with an eye for functionality and aesthetics.

The control building features rounded corners and various design features to be visually detached from the bridge deck. This makes the building a recognizable element on the site and contributes to the overall appearance of the bridge.