Kandt Contracting and foundation company: innovation and sustainability in foundation work

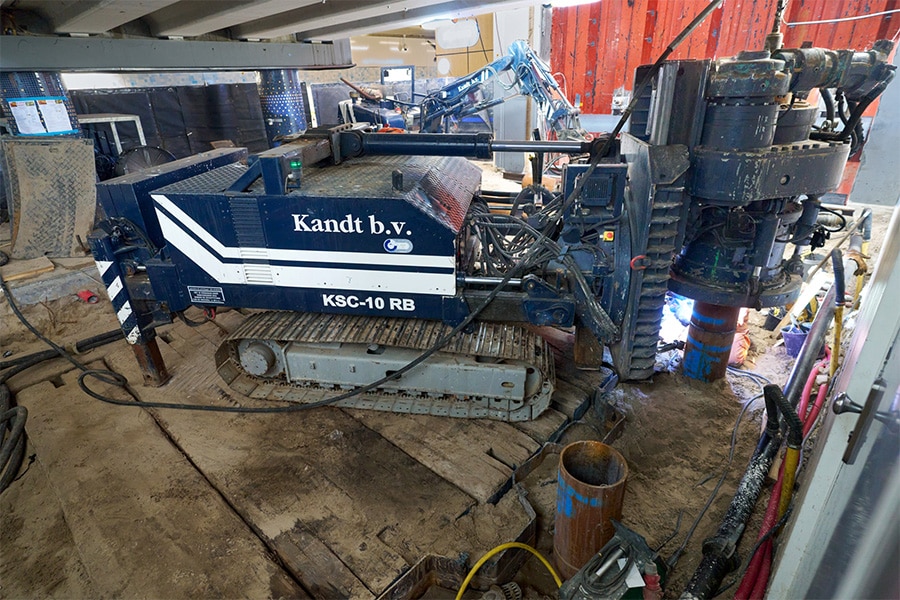

Kandt Aannemings- en Funderingsbedrijf BV, founded in 1978, has become a renowned name in the civil engineering, infra and rail industry. From an old garage near the home of founders Arie and Ria Kandt, the company grew into a medium-sized player under the current leadership of son Marco. With specialist machinery and a smart working method, Kandt offers a suitable solution for every foundation challenge.

Innovative and flexible

"Still rebuilding and modifying machines is one of our unique areas of expertise," says Marco. "By continuing to innovate as well as investing in sustainability, almost every project is feasible and doable." Each project is unique in terms of situation, complexity and challenges. "Thanks to the expertise of our team, as a subcontractor we can think along at an early stage, provide technical support and custom solutions. In doing so, constructive cooperation with all parties involved on the project is essential."

Never stand still

Marco observes that -just like the civil engineering industry itself- technical developments never stand still. "And that also applies to Kandt! We continue to develop and have all the modern techniques and skilled people in house to take the right steps. This allows us to realize the most diverse foundation works. From standard work to highly specialized issues," says Marco. For example, the company has years of experience with vibration-free foundations, also at locations that are difficult to reach.

Emission-free and vibration-free

Kandt wants to keep up with technological development in which sustainability plays an increasingly important role. That is why the company is putting more and more effort into low-emission and partly emission-free equipment. "We commissioned a fully electric 80-ton crawler crane at the end of last year and we are currently building in-house our first low-emission LEKA drilling rig," says Marco. "With this, as with the silent piler, we can process both piles and also sheet piles emission-free and vibration-free." The company is thus taking significant steps toward more sustainable operations, making a positive contribution to reducing emissions on projects.

Welding capacity further expanded

"Furthermore, we are going to build a new 4,000 m² welding and construction workshop in 2025 to further expand our capacity," Marco says. The company is NEN-EN 1090-2 certified and performs all qualified welding work up to execution class 4 in-house. "We will also install solar panels and heat pumps here to be self-sufficient in terms of energy," Marco adds. It is clear that Kandt is trying to make its investments as responsible and sustainable as possible.

Divergent foundation projects

"Both specialized knowledge and project-specific equipment enable us to work on the most challenging sites and under a variety of conditions," Marco continues. He explains that Kandt specializes in retaining and load-bearing structures, such as sheet piling, cofferdams and pile foundations for tunnels, bridges, viaducts and quay walls, but can also be deployed for specialized issues. "Think of projects in inner-city areas with limited space, or locations where vibration-free or from the water is required." To illustrate, Marco mentions projects such as the OVT Zuidas in Amsterdam, the Schiphol Bridge A9 and RIF010 in Rotterdam. Not the least projects, in which Kandt proves time and again to be a solid partner in foundation engineering.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Kandt Aannemings- en Funderingsbedrijf BV.

Contact opnemen

Contact opnemen