SmoothRide keeps traffic moving

Topcon promotes traffic flow on German highway during renovation

Road construction company Matthäi used Topcon technology to repave the busy B420 highway near Fürfeld in Rhineland-Palatinate, Germany. SmoothRide helped the contractor meet tight deadlines despite challenging working conditions.

One of the biggest challenges for Matthäi during this project was avoiding long traffic jams due to road closures. Therefore, it was decided early in the process that work could only be done on weekends. In order to still meet the tight deadlines, the teams had to work a total of three weekends, each time renewing 1 kilometer of road surface. In total, about 40,000 m² of asphalt and binders were used and 9,000 tons of material had to be milled, moved and re-laid. The SmoothRide solution helped Matthäi, among other things, to capture and use data optimally during the work, so that the execution went quickly and smoothly.

Weeks of work saved

Normally in road surface renewal, the surveying process is a time-consuming task with a high probability of costly mistakes. Surveyors hammer a post into the ground along the shoulder every five meters. Then every 20 meters they have to measure the cross section, evaluate all photos, prepare marking diagrams and check that all relevant data are documented. Using this regular method, designing the complete road would have taken about two weeks. But instead, the Topcon team placed an RD-M1 scanner on the roof of a car and drove along the entire route to be renovated in less than an hour. That way, Matthäi and Topcon captured millions of points in just 50 minutes.

"Based on a thinned-out 30-centimeter point interval, we mapped the entire road," said Frank Pohl, team leader of land surveying at Matthäi. "Then we discussed the critical points and quickly found solutions to various problems. The team was able to easily smooth out the unevenness in the planning model, which would certainly have caused problems. They optimized the geometry so that the slope of the new road surface became a constant 1.5 percent, resulting in a perfect end result. The curves in the road were also given perfectly smooth slopes. Thus, the planning phase that is normally enormously time-consuming was completed in just two days."

Results through data

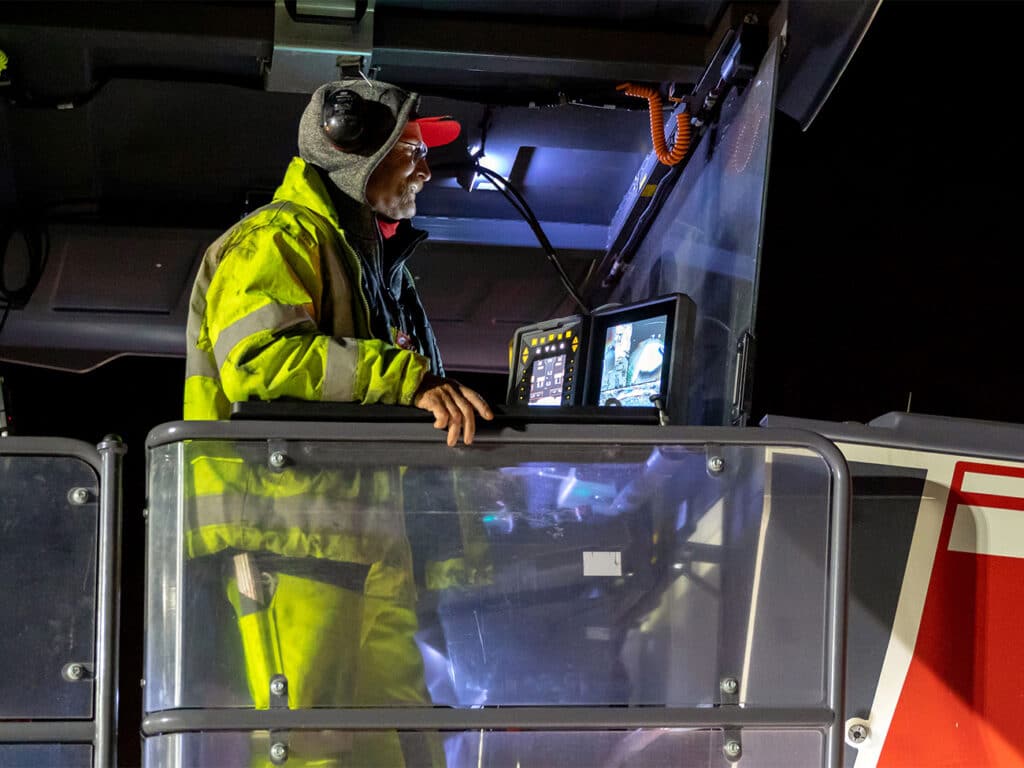

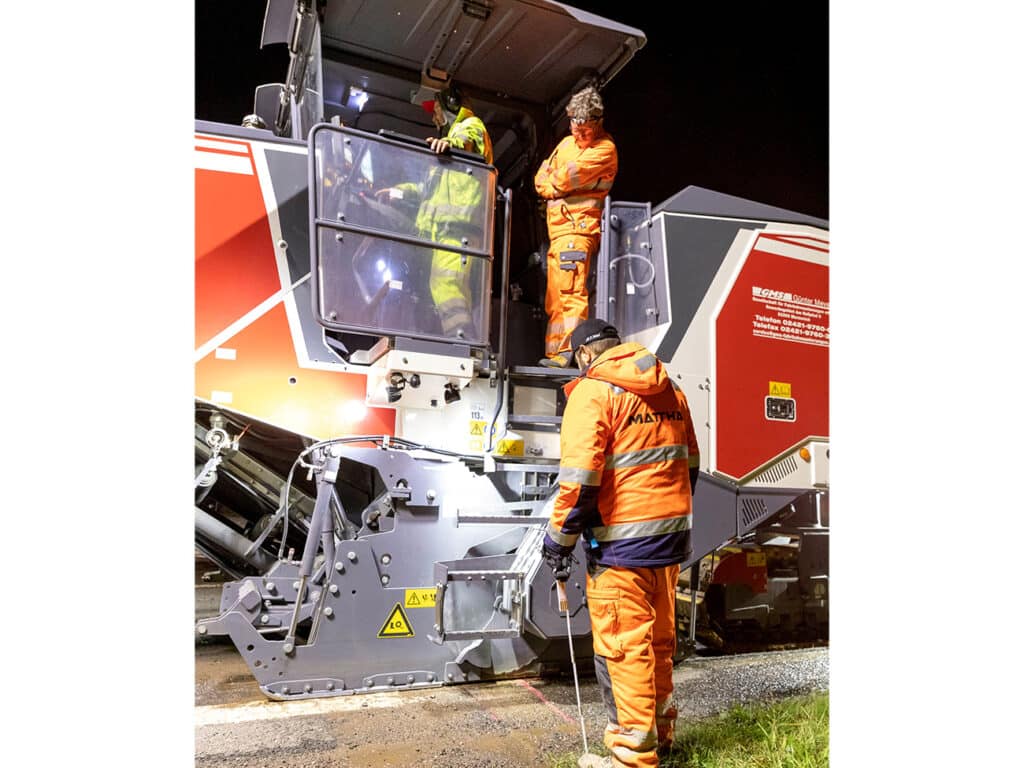

The next step was to send the completed model to the milling machines. SmoothRide uses GNSS for positioning, allowing users to machine only those road sections where milling is required. This allows milling with millimeter accuracy of the difference between the existing road surface and the design. GPS-prepared machines were fitted with the 3D components. This took only 20 minutes, said Raimo Vollstädt, support engineer at Topcon. "Thanks to SmoothRide's technology, everything is automated, so the milling machine always knows the exact location on the road. This saves a lot of time and it means that the machine never has to be adjusted, which is especially useful for night work in the dark. Moreover, it allows multiple machines to be used at the same time. This makes the process even more efficient, which is essential when working under high time pressure."

The milling machines were sent out four times a night according to the planned design, over the six-meter-wide and one-kilometer-long section. 16 trucks were on site to transport the milled asphalt to the mixing plant, where it was processed for reuse in the binder. Says Vollstädt, "The team had to complete all milling work on the road surface up to the Fürfeld exit before the road could be reopened. Thanks to the efficient process, the work was completed an hour ahead of schedule."

Open earlier than expected

This efficient and precise milling process then allowed asphalt to be paved to a constant thickness. The asphalt paver was able to lay the binding layer exactly five centimeters thick everywhere, and the road could be asphalted the same day. The use of Topcon technology allowed traffic to regain access to the road as quickly as possible, even in the weeks between road closures, minimizing disruption to daily life. The B420 was able to reopen even earlier than expected.

Klaus Korman, site manager at milling company GMS, was impressed with the results. "Thanks to SmoothRide, every part of the process went smoothly, without complications. The technology did exactly what it promised. We have had nothing but good experiences with SmoothRide and fully believe in Topcon's solutions. Now that the process is complete, this part of the B420 is like new again and therefore much safer and more comfortable for all road users."