DAF rigids: champion of diversity

The year 2023 will go into the books at DAF Trucks as an absolute record year with 69,800 vehicles produced and 53,700 registrations. The highest number ever in the history of DAF. The Dutch truck manufacturer has also regained its market-leading position in the rigid truck segment. This year promises to be another great year, as the range will be further expanded and the body friendliness of the New Generation DAF rigids will improve considerably thanks to the unique Plug & Play program. And that offers great advantages for customers, dealers and bodybuilders alike, as we experienced during a demo at the Eindhoven factory site.

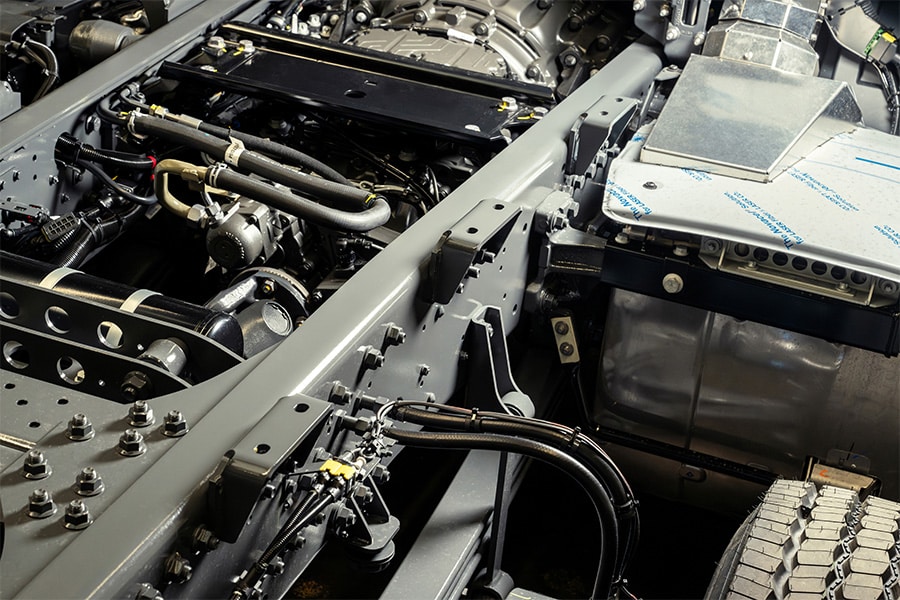

Exactly one year ago, we were first introduced to the New Generation DAF construction vehicles in a challenging quarry in South Limburg. What we could note back then was that this generation sets new standards in terms of efficiency, safety and driver comfort. Since then, the Dutch truck manufacturer has been anything but idle. Based on the so-called Transport Efficiency philosophy, DAF is now increasing the body friendliness of its rigids. To this end, it is expanding the Plug & Play program, increasing payloads by up to 160 kilograms and offering new options for chassis beam hole patterns. "Every customer wants his own body. With these latest developments, we lay the perfect foundation for all customers right from the factory," says Raoul Wijnands, Manager of Testing at DAF Trucks. "That makes us champions of diversity."

Dream wedding

The Plug & Play program is unique in the world and was developed in close cooperation with 25 leading European bodybuilders. "Bodybuilders are becoming more and more critical. Logical too, because a body is also increasingly complex," Raoul acknowledges. "We have mapped all these wishes and requirements to optimize the specification, ordering and bodybuilding of rigids." The program allows the customer, bodybuilder and dealer together to easily select pre-specified and customized plug-and-play body options in DAF's ordering system. The underlying idea is that the "marriage" of a body to the DAF chassis should be as simple as possible. After mounting a body on the chassis (on the factory-fitted body mounting modules), the connectors are connected and the body is immediately ready for use. DAF rigid truck chassis therefore now leave the factory fully prepared. This ensures fast assembly and a high-quality and error-free first-time-right integration of the body and vehicle.

Universal preparations

Obviously, there are many more bodybuilders active than the 25 major parties with whom DAF has rigged the Plug & Play program. That has led to universal ex-factory preparation for five specific bodies, concerning hookloaders, cranes, tippers, mixers and skiploaders. "These types of bodies account for about 90% of the market," says Cornelis van der Lee, Director Rigid and Vocational Trucks at DAF Trucks.

"From now on, customers and dealers can work with virtually any bodybuilder to specify the universal ex-factory preparations needed for ultra-fast body mounting. Not only is the chassis prepared, DAF also takes care of the correct placement of the connectors. As a result, the dashboard information display (DIP) and the switches in the cab communicate directly with the body. This greatly reduces turnaround time at the body shop, so that newly ordered New Generation DAF rigids can be deployed much sooner."

Sharper calculation

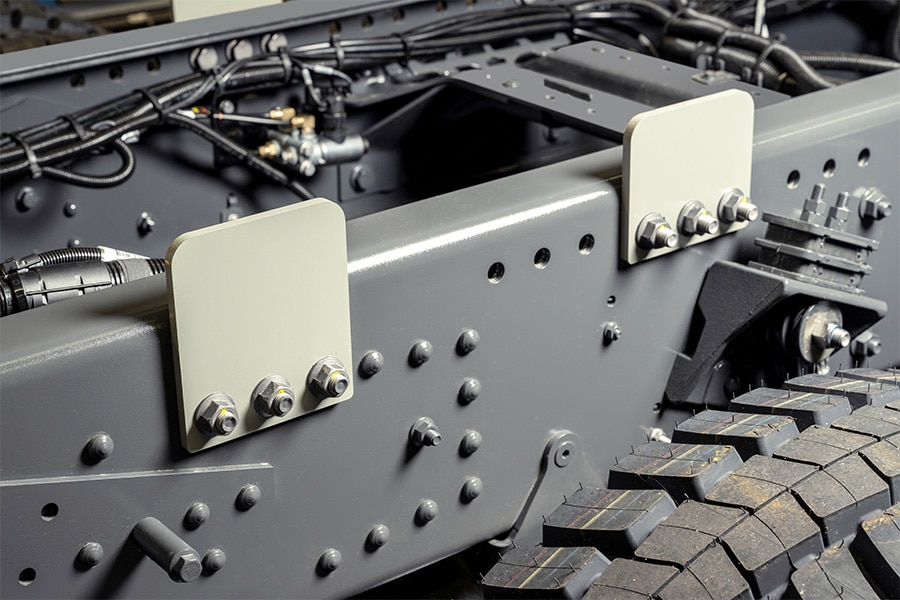

Overall, ordering and especially specifying the right chassis for a specific body is quite a task. "Thanks to the Plug & Play program, this is now much more efficient and straightforward. And the quick turnaround time and error-free first-time-right integration means that a bodybuilder can also make much sharper calculations," Raoul emphasizes. "After all, all the parameters are much better aligned." Insiders no doubt know that a DAF chassis has long been supplied with a 60-millimeter hole pattern. "Here, too, we are coming up with a new development, because in order to meet the specific requirements of a bodybuilder, a 50-millimeter hole pattern is now also available. Over the entire length of the chassis. Flexibility is in the DNA of every DAF." By this, Raoul is also referring to the Engine Aftertreatment System components, which can be fitted to the chassis in different places, tailored to the bodybuilder's specifications. In turn, the bodybuilder also has a choice of standard Body Attachment Modules (BAM).

DAF also ensures the proper placement of

the connectors.

Unparalleled ease of operation

Plug-and-play, as mentioned, is also the control of the superstructure. Numerous options are available for operating the superstructure. Connections are possible both analog and via a CAN bus specifically intended for the body. This allows all signals and warnings to be clearly displayed on the digital information display. To this end, DAF has as many as 51 standard pictograms and 31 standard warning texts (in green, yellow and red) available, which can be accompanied by various attention or warning sounds. In addition, a full range of programmable MUX switches is available for operating the superstructure. These are available separately and can be positioned and grouped at the dasboard according to driver preference. This too adds to the unparalleled ease of operation of the New Generation DAF trucks.

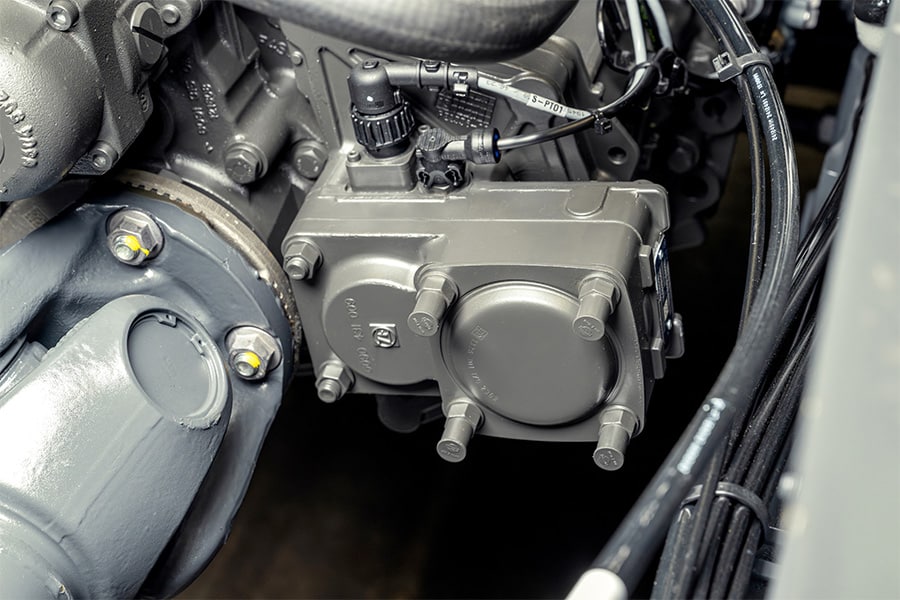

Always the right PTO

Operating a body is usually done via a power take off (PTO). Did you know that DAF offers a choice of as many as 68 PTO options? It ranges from 11- and 1-hour positioned clutch-independent engine PTOs to clutch-dependent gearbox power take offs. All of these PTOs are available with a pump or flange connection. DAF even offers the ability to operate up to three PTOs independently at the same time. Another striking feature of the rigids is their low kerb weight. And that is now brought down even further by a newly designed, all-aluminum underride protection at the rear: the Rear Underrun Protection. According to its makers, it is 28 kilograms lighter and more robust than its steel predecessor. Additional weight savings are achieved by combining the rigidity of the chassis beams of the truck chassis with the rigidity of the superstructure subframe. This makes additional chassis reinforcements unnecessary and results in weight savings of up to 135 kilograms. This further increases payload capacities without compromising on chassis rigidity and service life.

In short, with all these efforts, DAF Trucks is significantly increasing the body friendliness of its New Generation DAF rigids. "That makes us offer the best proposition for the owner, bodybuilder and driver. Because also in terms of efficiency, safety and driver comfort, our latest generation rigids make the difference. At least, that's the feedback we get from our customers. And that makes us quite a bit proud," Raoul concludes.