Smart control solutions during energy transition

Schoonhoven company celebrates 50th anniversary in 2024

Next year is a celebration at VSE Industrial Automation. The Schoonhoven-based expert in industrial automation and motion control will celebrate its 50th anniversary. The company has reached this milestone by consistently translating its expertise into innovative, high-quality total solutions in a customer-oriented manner since its establishment. Both for infrastructure, construction and industry. Under the motto "Engineering the future, powered by smart energy," this approach will also be tightly maintained for the coming years. "With our products and services, we want to continue to contribute to a sustainable and circular society," says Commercial Manager Radboud van Dusseldorp.

The past edition of the Energy Trade Fair, the largest business networking event in the context of energy transition in the Netherlands, was an excellent opportunity for VSE to once again demonstrate its knowledge and expertise in the field of controls and drives to the full. This happened on October 15, 16 and 17 in the Brabanthallen in 's-Hertogenbosch. "As one of the most renowned drive specialists in the Netherlands, we demonstrated once again that we can offer more sustainable, greener and smarter solutions for various clients that fit into the world of today and tomorrow," says Radboud. "A digital world where, within the energy transition frameworks, the need for dynamic energy supplies continues to grow, but where we also increasingly experience the limitations of the existing grid infrastructure. At the same time, applications are becoming increasingly complex and customers more demanding. It is precisely at that intersection of developments that VSE operates. With high-end and in-house developed software and hardware of top quality, a tiptop service and an approach strongly focused on project-based acting, cooperation and partnership."

Complete solution

Started in 1974 in a basement under an old garage in Stolwijk, the then one-man business N.H. van Schelven Elektrotechniek (VSE) has developed over the years into a more than full-fledged player in the land of electric control and drive. The website of the certified company features several success stories that confirm both the expertise of the approximately 45 VSE specialists and the breadth of the playing field in which the company operates. In recent decades, for example, VSE has designed a variety of solutions for its composite customer base. Among them are a large number of energy-efficient controls for bridges, locks, pumping stations and barriers, including the drives that VSE combined with the universal building block 3B-Bridges from Yunex. But the company can also provide fine references in automation and around the electrification of heavy earth-moving machinery, aggregates and other construction equipment, among others. "Furthermore, we help industrial companies save energy and reduce connection power," Radboud continues the enumeration. "Whatever the question or approach, we have everything ready to be involved in a project from beginning to end and to think along with it. This is precisely why we can provide the most complete and project-specific solution. For almost 50 years."

Value for every sector

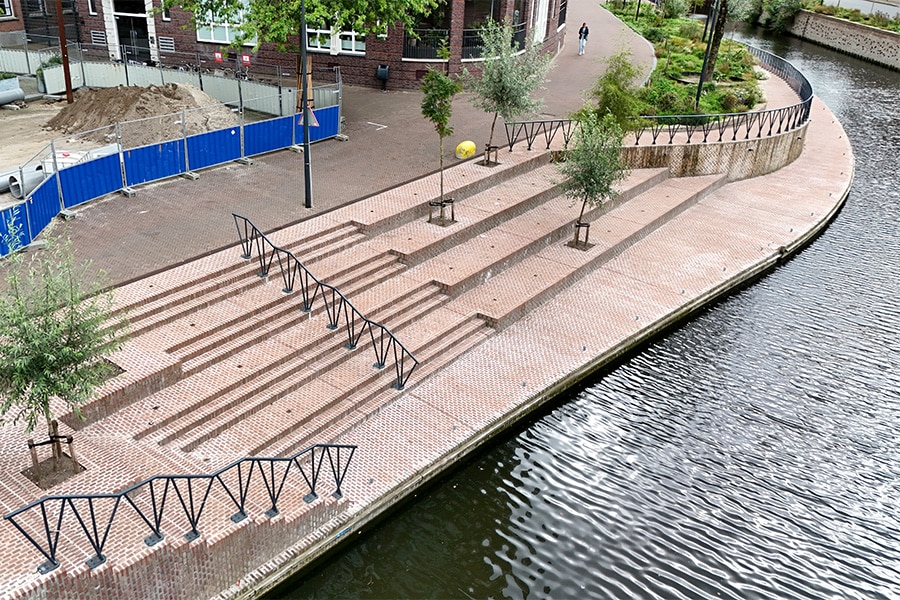

Moving large loads with a low connection value? Sustainably switch from diesel to electric? Worry less about stability problems? Making business processes smarter, more efficient and greener? Whatever the challenge, VSE is happy to help its customers use available energy more effectively. The reference projects below tell the story.

Infrastructure: This summer, Rijkswaterstaat had the Haringvliet Bridge's 2,000-ton valve and its technical installations and systems replaced. VSE took on the high-end controls for the actuators for client CMCH (Combination Mobilis Croonwolter&dros). The controls were used in combination with the universal bridge control 3B-Building Block developed by Yunex on behalf of the Department of Public Works for standardized operation, control and monitoring of movable bridges. VSE has extensive experience with the 3B-Building Block and previously applied it to the Wantij Bridge. The VSE project team took care of hardware and software engineering as well as project management and panel construction, delivered the highest and most reliable quality, and as a partner completely relieved the client.

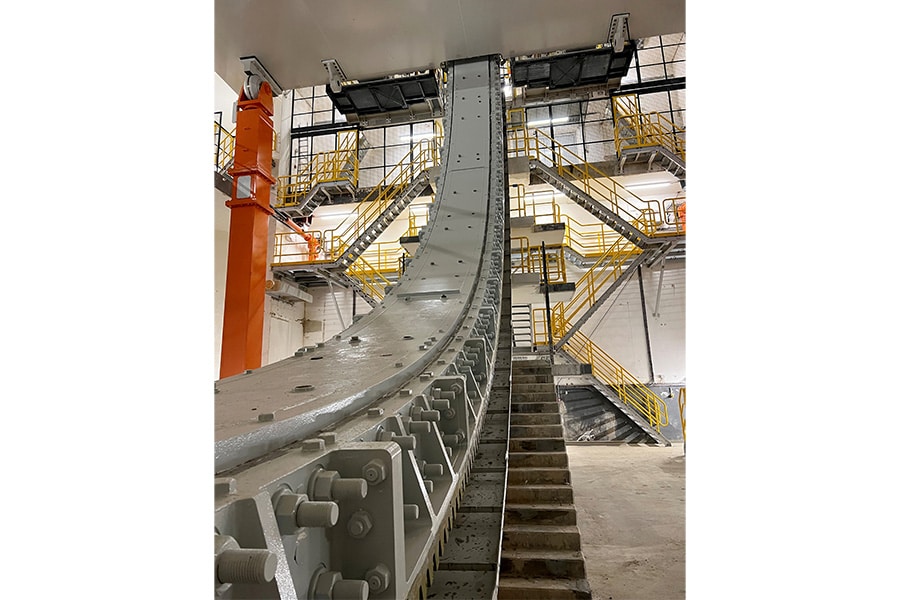

Construction: Woltman built the first fully electrified 100-ton foundation machine for BAM Infra Nederland. VSE supplied the high-end controls, batteries and electric motors. The smaller motor is automatically used for auxiliary functions, the larger one for the main function. The motors switch off automatically when no power is required. The daily capacity is 1,200 kWh. Of this, 1,000 kWh is in a battery container and 200 kWh is in the machine. The machine rides independently off the flatbed trailer without a battery container and can start drilling after connecting the battery container. The batteries are charged within 10 hours for 90%.

Industry: For two warehouse cranes built by Torsit, VSE applied so-called UltraCaps. These can briefly store and release a lot of energy. They are part of Smart Power Management from Siemens. The locally stored braking energy of the cranes is used to briefly supply peak power for upward movement. This allows the cranes to run on a 16 instead of 32 amp connection. And that's for an 18 kW motor! When fully charged, the UltraCaps can deliver energy back to the grid. They are also very suitable for application in infrastructure, such as bridges.