11 years of the CO2 performance ladder. What has it brought?

CO2-reduction is now an integral part of everyday life. Increasingly, government and society expect the infrastructure sector to play an active role in CO2-reduction in the Netherlands. How do we gain insight and control over our organization's emissions? Which CO2-reduction measures is Mobilis taking?

The CO2-Performance ladder is the Netherlands' sustainability tool that helps companies and governments reduce CO2 and costs. Within operations, in projects and in the chain. The Ladder is used as a CO2-management system and used as a procurement tool. From the CO2-Performanceladder ladder, Mobilis has developed a methodology to reduce CO2-emissions. The company now has a clear picture of CO2reduction, but also of circularity and climate adaptivity, and always tries to look project-specifically at measures that really make sense.

Mobilis has the conviction and the motivation to make products and processes more sustainable and to continue to take initiatives in this respect, so that the company can continue to contribute to the mobility of the Netherlands in the future. We align our ambition with the objectives of our customers. This means that Mobilis contributes with targeted initiatives to energy-neutral assets in 2030 and to developments to save and generate energy, and to make circular use of materials and sustainable design possible.

Wind Farm A16

Because circular and sustainable construction is high on Mobilis' agenda. As with the new A16 wind farm with fourteen wind turbines with a tip height of 150 to 210 meters. They all need solid foundations. With an eye on the future where Mobilis wants to found many more wind turbines, we invested in a flexible steel box to pour the foundations. With just one box we were able to realize all the foundations and with careful use this formwork can last for more than 100 masts.

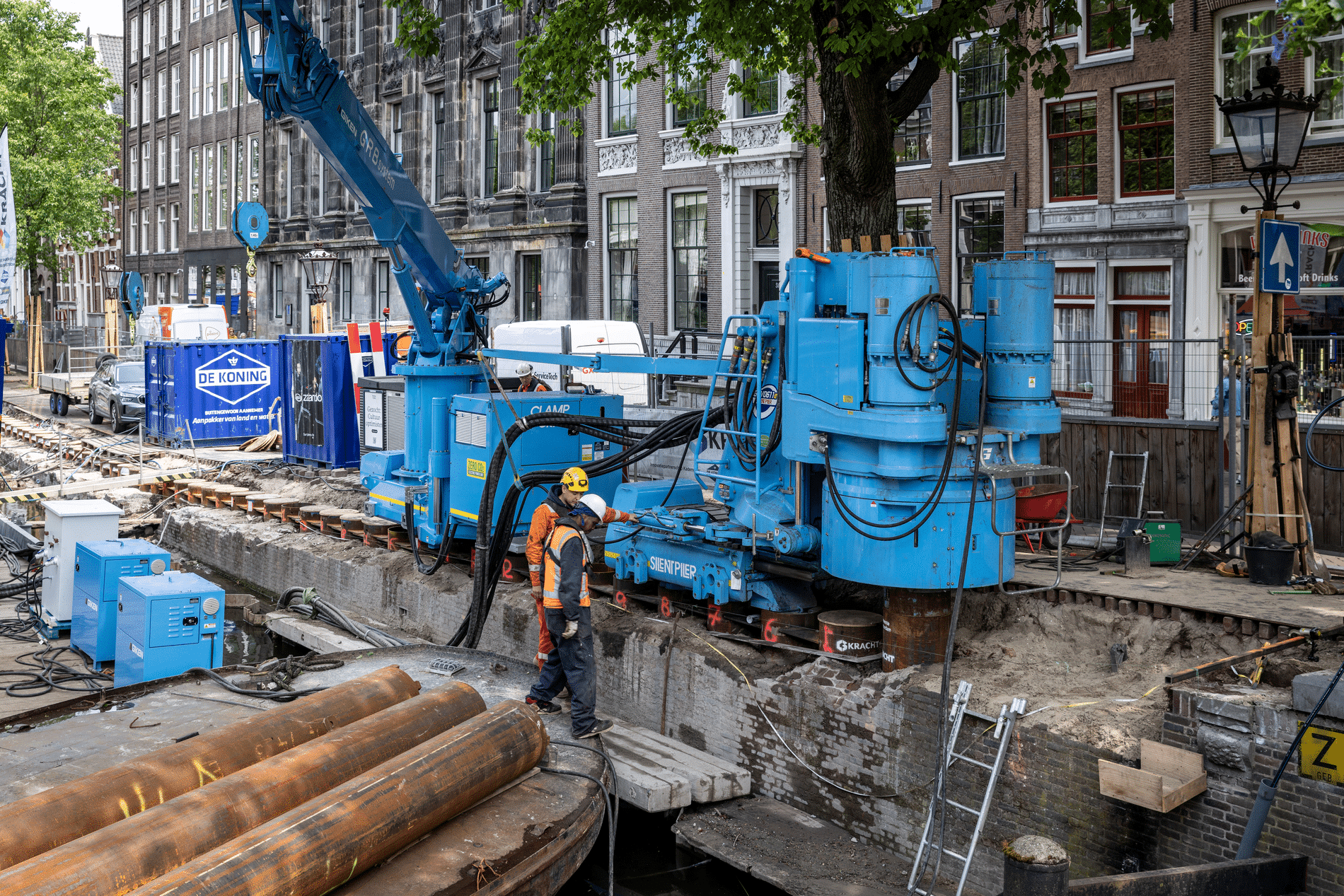

Amstel Stream Bridge

Another fine example of sustainable construction by Mobilis is the Amstel Stream Bridge, an important link in Amsterdam's ecological network. A graceful bridge and a safe place for pedestrians and cyclists, as well as a green shelter for bats, birds, fish and insects. The green median strip between the lanes with native flower-rich herbs attracts bees and butterflies. Nesting opportunities for these bees are included in the brick walls and pylons. The bridge also includes many hiding, nesting and sleeping places for larger animals. The concrete center piers contain nurseries for bats, nesting boxes for 10 species of birds such as kingfishers, various swallows, tits, sparrows, wagtails, starlings and jackdaws are included in piers and edges. Between the underwater piers, cages of dead river wood and landforms provide habitat for fish and mussels. The bridge is now home to at least 20 local animal species.

Corbulo Tunnel

At the RijnlandRoute, Mobilis has a world first with direct sunlight at the entrances to the Corbulo tunnel using fiber optics. The system (Solar Optic Fiber) with lenses on the tunnel roof and glass fiber for transport brings sunlight up to 100 meters into the tunnel without loss of quality. A sustainable solution because lighting in tunnels is a real energy consumer. The innovation can lead to a reduction of 10 to 20% of the total energy consumption of the tunnel in the RijnlandRoute.

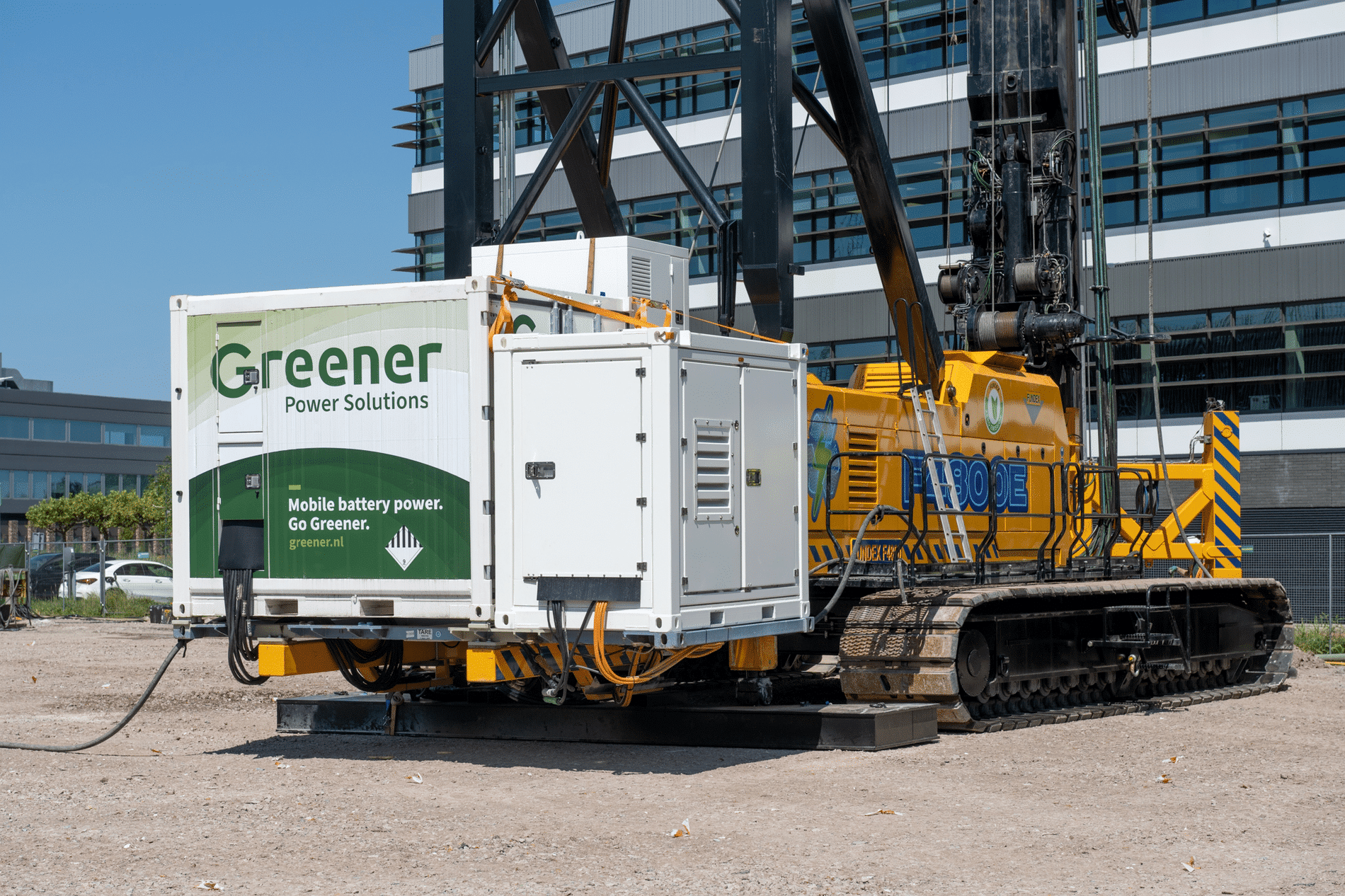

e-CO2tainer

The e-CO2tainer finally is a breakthrough when it comes to green power on the construction site. Mobilis devised the smart unit that allows the construction tainer, electric equipment and the electric vehicle fleet to run on green electricity. Together with Electure, the e-CO2tainer bit by bit the construction sites at TBI and beyond. After a period of pioneering and pilots, it is now time to speed up the emission-free construction site. The e-CO2tainer is mainly in use on Mobilis and TBI projects, but any builder can use it on his own construction site.

Mobilis wants to share knowledge and innovations, especially when it comes to sustainability.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Mobilis.

Contact opnemen

Contact opnemen