An ERP system for the GWW

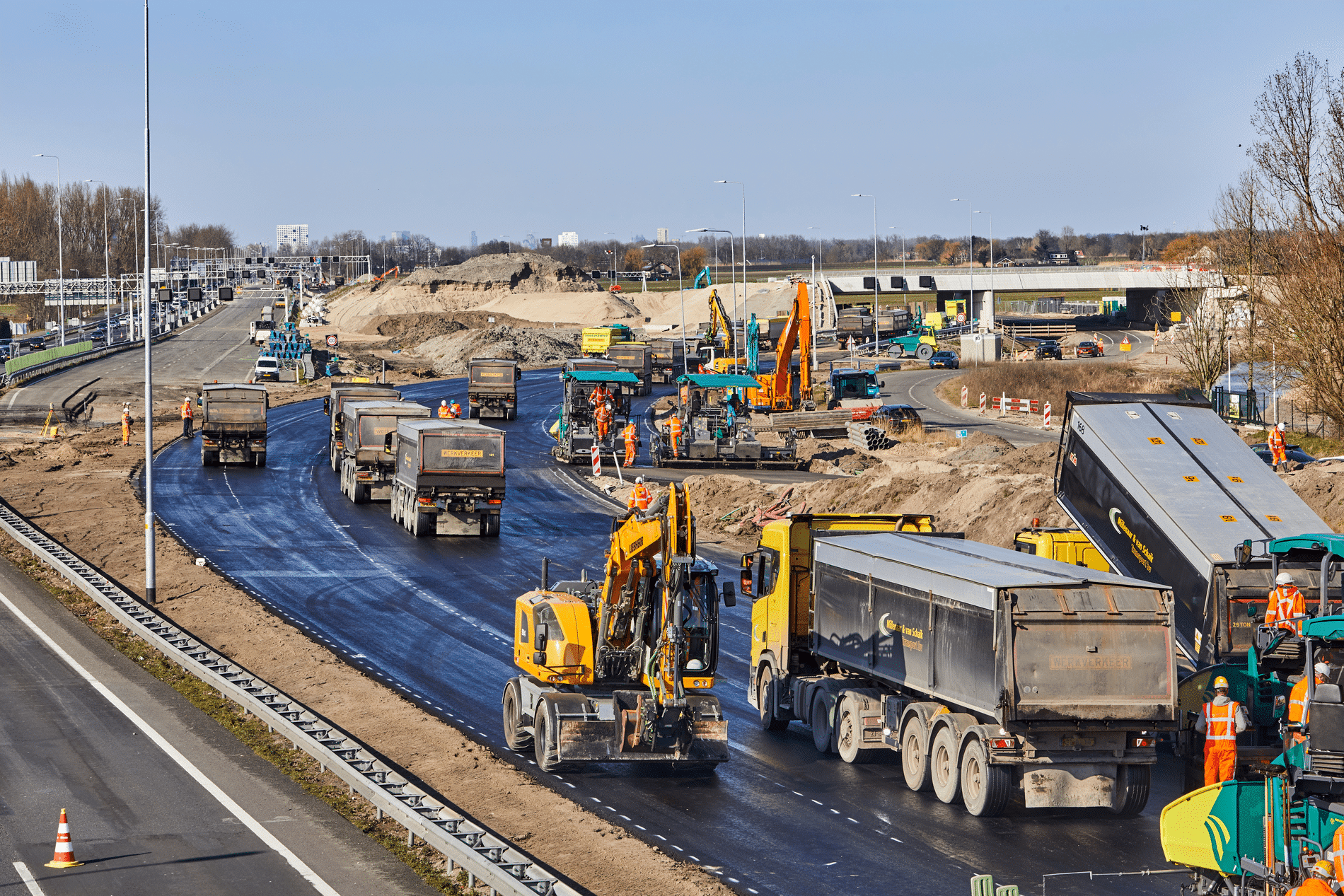

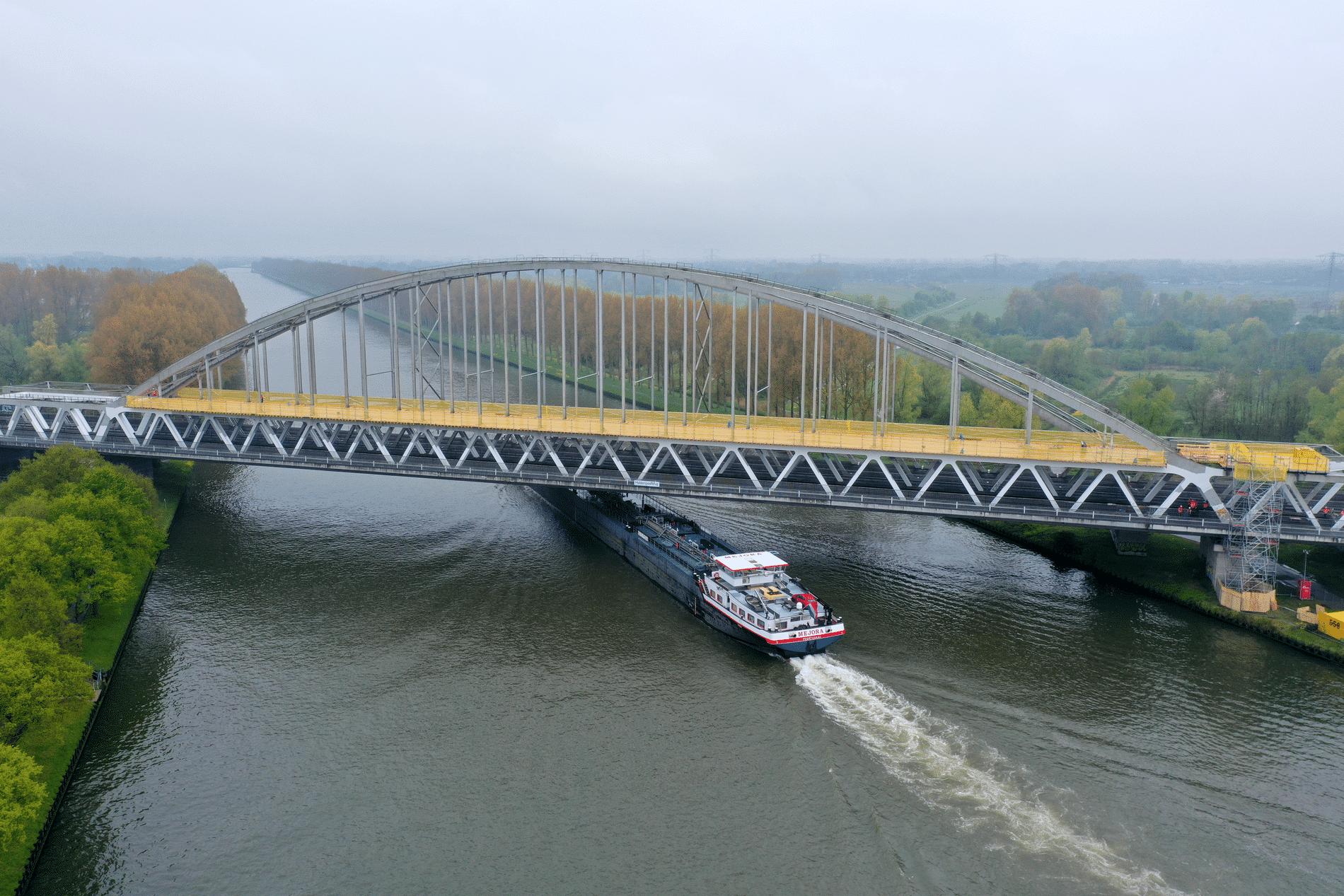

As part of engineering, civil engineering has specialized in individual areas of expertise, such as road construction, hydraulic engineering or foundation engineering. ERP has also become increasingly differentiated in recent years, now offering specific civil engineering functions directly tailored to their sector. In the following we want to look at the most common functions and modules of an ERP system for GWW.

Calculation

An ERP system can provide in addition to a price quote for the material, personnel, tools, or third-party services, including a free cost estimate for that allows basic, sales, and flash calculations. In addition, input of standard calculations is possible through various interfaces. Determining and tracking costs also plays an essential role in civil engineering. Multi-level estimates can be made through the system, and cost recording and billing controls can be integrated. Similarly, information about subcontractors can be integrated at this point and included in the calculation.

Administration

In addition to the usual project billing functions, ERP systems specifically designed for civil engineering also offer some other modules. For example, individual projects can record and allocate exact personnel, material and equipment costs. Hours are easily recorded and allocated to the project before being forwarded directly to financial accounting and costing.

Billing

Also, final charges and supplement processing and billing are easily possible. In addition, ERP systems take into account all invoices, down payments, partial and final invoices, allowing flexible management. Prepayment plans, bank guarantees, etc. can be managed easily and efficiently. Detailed liquidity management is also available. ERP systems can help maintain control of their own liquidity by optimizing all invoicing.

Important for companies with larger and long-term projects is always the management of subcontractors. With this feature, price requests, surcharges and awards can be presented in a holistic process, ensuring transparency in collaboration.

Resource management

Besides asking what raw materials are needed, making wholesale for what project, ERP systems have through detailed machine management that manage the internal and external devices in mind. Equipment master data can be easily integrated into accounting, cost accounting, resource planning or cost accounting. Not only can equipment costs be captured, but their disposition and predictive maintenance can be ensured. Third-party equipment can be displayed and integrated with respect to their availability and rental costs. Since projects are now often calculated very sparsely, all costs must be weighed against clearly estimated resources at each stage of the project's preliminary cost estimate.

CAD

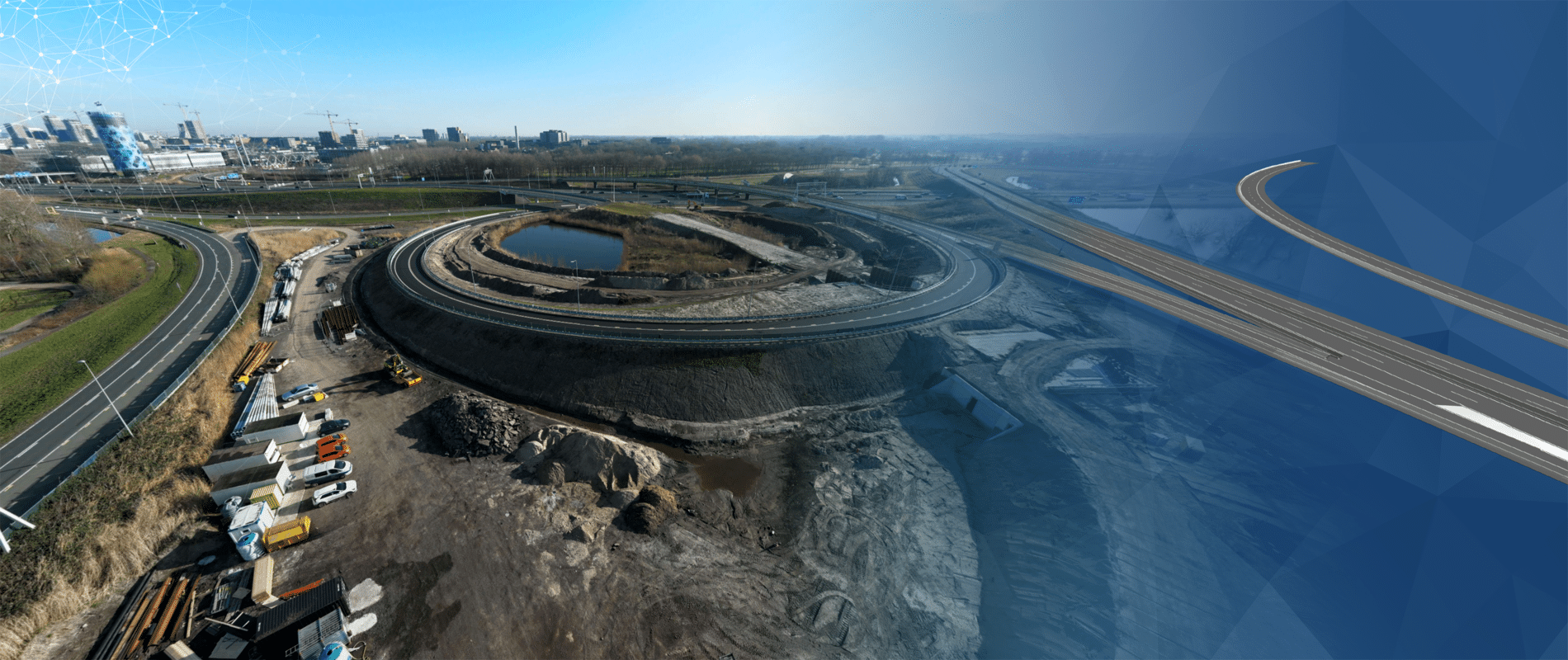

In addition, ERP systems in civil engineering offer many other functions. A part or an entire object can be measured and recorded. Many systems offer a 3D representation of the object, which is a great help in planning and during the process, especially when multiple companies are involved in a construction project at the same time. Some ERP systems also have their own calculation models specifically tailored to civil engineering.

ERP system for the GWW

Would you like more information about the possibilities of ERP software for the GWW, what to look out for when choosing an ERP vendor or are you curious about what ERP costs in your case? Then please visit www.erpoverzicht.nl.