Unique sonic drilling method combined with probing makes the impossible possible

"Probing is probing and drilling is drilling, but the combination of the two, that's what makes it unique!" Speaking is Rutger van Goethem, Account Manager at Eijkelkamp SonicSampDrill. The company is part of Royal Eijkelkamp and makes a continuous contribution to a safe and healthy living environment thanks to more than 100 years of experience and expertise in products and total solutions for soil and water projects. "Quality, reliability and innovation are deeply embedded in our corporate DNA. We always seek appropriate solutions to rapidly changing customer requirements and strive for continuous improvement of our products."

Dutch invention

"Our Eijkelkamp SonicSampDrill products are the result of innovations and 'out of the box' thinking. To focus even better on market demands from drilling companies to probe and from CPT companies to be more successful in difficult geology, Eijkelkamp SonicSampDrill and GeoPoint Systems have joined forces since February 2018. Under the name Eijkelkamp GeoPoint SoilSolutions, they are working on innovations that are transforming soil testing capabilities. The collaboration came about when Eijkelkamp SonicSampDrill and GeoPoint Systems jointly developed a unique concept to integrate probing into a sonic drilling system. The "Dutch Cone," or sounding cone, is a Dutch invention that is being used more and more worldwide. However, the limitations in some soils do not make it applicable everywhere."

SonicCPT combines two technologies

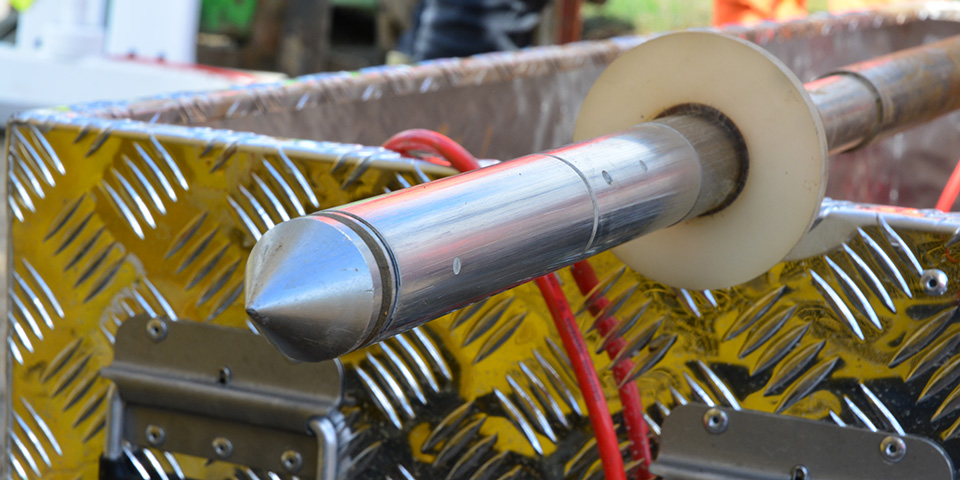

"By always thinking further about how we can make the technology even better and faster and how it can be used in any type of soil, new products emerge. Like SonicCPT." Van Goethem explains, "With SonicCPT, two technologies are combined; sonic drilling with probing. Because sonic vibrations can be added to the probing process when needed, you can penetrate layers that offer too much friction for conventional CPT. Ideal for applications in clay layers, as is common in Dutch soils. The electric cone can even measure point resistance and mantle friction while the vibrations are switched on."

Tunnel project in Bern, Switzerland. The Drill'n CPT offered a solution. When a boulder was encountered at a depth of six meters, probing was easily converted to drilling. Thus, the desired depth was still achieved.

Drill'n CPT

"For harder layers, however, the SonicCPT proved not quite the solution yet. Especially abroad, the geology is very different and varied. There had to be a suitable product for that too. Further development led to the Drill'n CPT." That is a 20-ton fully automatic sounding device that can be used with a drill press. "With our Drill'n CPT tool, any (sonic) drilling rig can easily be converted into a CPT. It can provide continuous sounding measurement and as soon as it encounters a hard layer, one can switch immediately from sounding to drilling, without cumbersome operations or changing equipment. It is also the perfect combination to apply CPT testing at greater depths. These new products fill a great need. They enable our customers to work even more efficiently. With the revolutionary Drill'n CPT unit, for example, it is possible for drilling companies to easily convert their drill press into a CPT machine, which allows for increased applications and lower project costs." So good news for geotechnical companies specializing in foundation investigations, the mining industry, CPT and drilling companies. "You can now do a lot more with smaller and lighter machines." Van Goethem concludes, "Our smart CPT concepts are going to conquer the market!"