Largest ever temporary pumping plant stands in IJmuiden

In order to maintain the capacity of the water discharge that normally passes through Europe's largest pumping station, the Zwolle-based company, within a unique partnership with client Rijkswaterstaat and SPIE (responsible for the management and maintenance of the pumping station), signed in record time for the delivery of 24 of the 34 temporary pumps needed in total. Partly as a result, Rijkswaterstaat is able to meticulously manage the water in part of the western Netherlands and keep the area dry during heavy precipitation.

The IJmuiden pumping station normally runs on six mega-powerful submerged pumps. Four of them, dating from the 1970s, are driven by short-circuit anchor three-phase motors. The remaining two, equipped with highly energy-efficient permanent magnet motors, were installed in 2004. Using the six pumps, the pumping station can discharge as much as 260,000 liters of water per second from the North Sea Canal into the sea.

Defective

In late April last year, following a failure report to SPIE, which has been managing and maintaining the pumping station for the Department of Public Works under a performance contract since 2016, the technical failure of one of the last two pumps installed came to light. There was a defect in the drive motor. To prevent worse, Rijkswaterstaat decided to immediately shut down the other pump as well. It soon became clear that the defective pump had to be extensively examined and repaired, which takes quite some time. Therefore, a solution had to be found quickly in order to have sufficient pumping capacity at the start of the storm season in mid-October. The search brought the Department of Public Works and Vanderkamp Pumps together in June. "The message was crystal clear," Van der Kamp looks back. "Rijkswaterstaat specified the capacity it wanted and asked us if and how we could quickly provide a cost-friendly solution. A request to which we were naturally eager and able to comply. In July we received the order to supply 24 temporary pumps. Added to the ten made available by the Departementaal Coördinatiecentrum Crisisbeheersing I&W (DCC-I&W), this resulted in a battery of 34 pumps in total."

Cleverly placed

The installation of the emergency facilities took place from July to the end of September. It was a job that required quite a bit of work, especially due to the limited space on the lock complex, while the inconvenience to the surrounding area also had to be kept to a minimum. "To get the temporary pumps installed anyway, we went to great lengths with SPIE and Rijkswaterstaat during the design and engineering phase," says Van der Kamp. "For example, we took several hundred photos on site from different angles to virtually construct the environment. From this a 3D model was then created, in which both the pumps and the pipes could be placed."

After extensive testing and capacity measurement, the 34 temporary pumps have been on standby at two different locations since mid-October. The Kleine Sluis in IJmuiden (location A) houses eighteen pumps. Eight of these come from Vanderkamp Pumps' extensive rental fleet: seven propeller pumps, each with a capacity of 3,000 to 4,500 liters per second, and one diesel engine pump.

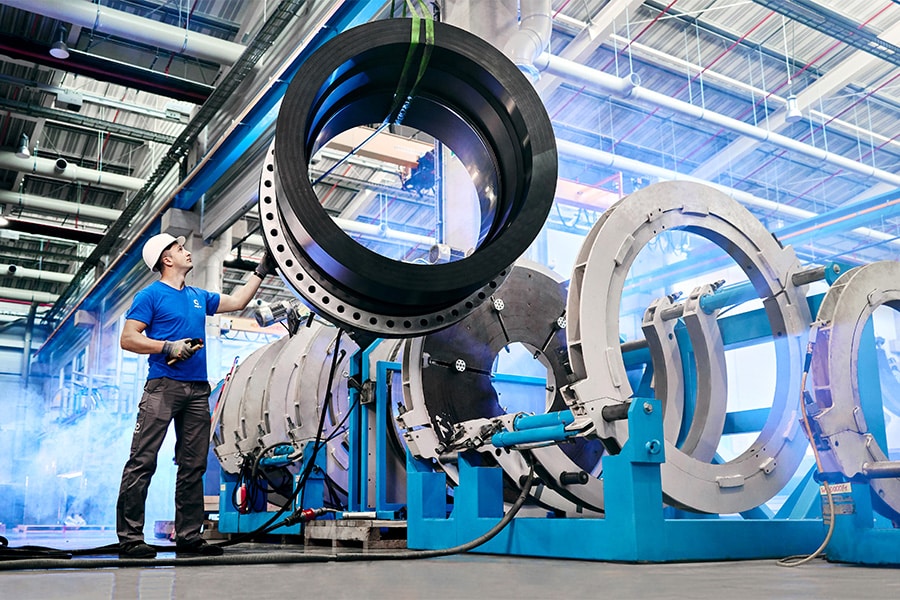

Along the outer head of the Middle Lock (location B), the company installed sixteen mixed-flow pumps, variants that can deliver more pressure than the propeller pumps. "To get all the pumps together, we had to do quite a bit of work," laughs Van der Kamp. "But it all worked out in the end. Through our widespread international network, we were able to get all the necessary equipment to the Netherlands."

Pump Insert

When additional capacity is needed due to weather conditions or the amount of water, the temporary pumps are put into operation at the request of Rijkswaterstaat. As for pump deployment, Rijkswaterstaat, together with the water boards involved, has determined a certain order for this. "First the pumps at location A go on, then possibly the pumps at location B," said Van der Kamp. "When our pumps need to be put into operation, we receive notification from Rijkswaterstaat five hours in advance that pumping needs to start. At that same time, together with SPIE, we initiate the execution plan. Part of this is taking the necessary safety measures on site. Then we make sure that at location A we switch on our diesel engine pump, the seven propeller pumps and the ten pumps of DCC-I&W to about 35 cubic meters per second. If necessary, we can then start on location B with the sixteen mixed-flow pumps. This can also be done within five hours. In that case, the pumps switch up from 38 to a maximum of 72 cubic meters per second."