Specialist concrete and masonry work for a green urban river

How a Brabant family business provided the technical backbone for nature-friendly embankments

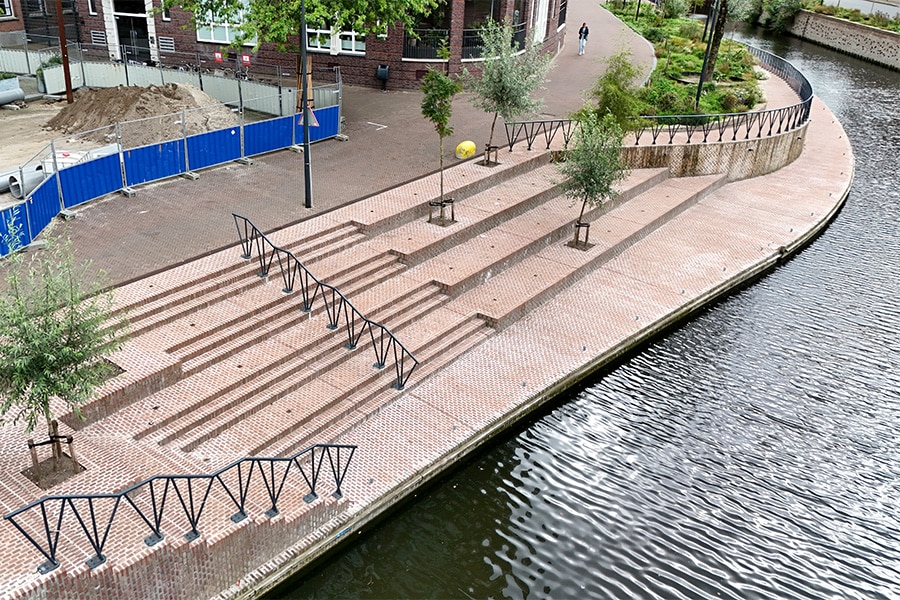

Gebr. Van de Ven played a crucial role in the return of city river the Mark to the city center of Breda. As a specialist in civil concrete work and complex masonry, they provided the structural base and visible work for the new quays; in which trees, plants and mosses will soon grow. "We rarely make something simple," says director Dirk van de Ven with a smile. "The more complicated, the better."

Originally, the quay walls were to consist partly of precast elements, but because of the complex curves and height differences, the general contractor decided to have the work done on site. "We ended up pouring the entire concrete substructure on site," Van de Ven says. "On top of that came the masonry that you see now on the waterfront."

That masonry is by no means a standard job. Between the concrete wall and the visible layer is a 5-centimeter cavity where substrate is applied. This retains moisture so that the wall can become overgrown. For the masons, this meant working with special mortar, developed at TU Delft and inspired by historic lime-tras mixtures. "There is no cement in it, so no harmful substances for plants," Van de Ven explains. "But you have to handle it differently: joints of 2 centimeters, don't apply it too hard, and take future plant growth into account."

Green in masonry

Although the greenery itself was not installed by Van de Ven, the contractor had to consider provisions for it at every stage. "The humid climate in the wall affects the joints. And there are even rosettes incorporated for trees specially selected not to get too big," Van de Ven says. "It's superficial vegetation, not root structures that break up your wall."

The specialty was not only in the details, but also in the use of materials. For example, the new Toll Bridge used recycled bricks. "Those came in different thicknesses and sizes, and the look was less uniform than new material," says Van de Ven. "That requires craftsmanship. Fortunately, we had a masonry crew that also works for the Efteling; men who just love such challenges."

Working together in an established network

Gebr. Van de Ven has been working with general contractor FL BV for about 25 years. "You know each other's way of working, know what you can gain from each other. In such projects it helps enormously that you don't start peeling off every problem legally, but look for a solution together."

This was necessary, as many drawings were modified during preparation. "Sometimes we got changes while we were already working. Then you have to switch quickly. As a small family business, we have short lines of communication. I myself am still sometimes setting formwork, and that makes us flexible."

Learning for the future

Although Van de Ven doesn't mention any major problems, the project did provide technical insights for the future. "You see how other parties look at details, and you learn from that. Also, the combination of concrete, masonry and nature-inclusive elements is something we would like to do more often."

Looking back, Van de Ven speaks of a successful project. "It turned out beautifully. We were perhaps a bit skeptical beforehand, but it turned out well; partly because of the cooperation. For us, this is exactly the kind of work we are hot for: technically challenging, with a visible end result that the city can enjoy for decades to come."