More discharge capacity thanks to specialized custom pumps

It cannot have escaped anyone's notice that the six pumps provided by Levvel in the renovated Afsluitdijk play a central role in increasing the discharge capacity for the future. Rijkswaterstaat's request was clear: the total pumping capacity for water discharge from IJsselmeer to Wadden Sea must be at least 235 cubic meters of water per second.

Finding a solution for this is no easy task. After all, in addition to being able to move large quantities of water, the pumps have to meet numerous other requirements. However, Flowserve - the supplier of the six pumps - rose to the challenge, and with success! Bert Waterink, Afsluitdijk Project Manager at Flowserve, is happy to explain the project.

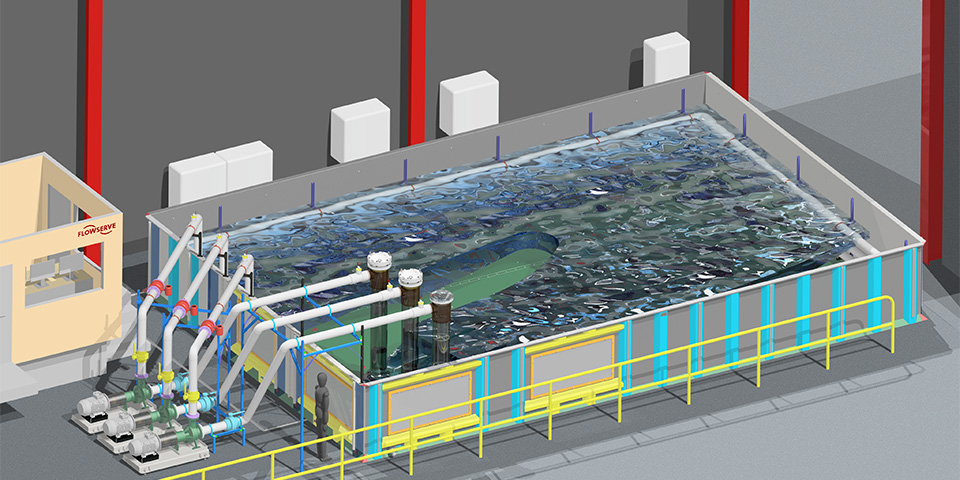

Testing of the inflow construction is performed by Flowserve in Etten-Leur.

Part of the overall design

"We had been in discussions for some time with the Department of Public Works, which had conceived the idea of using pumps to increase water discharge capacity," Waterink opens the conversation. "As a result of the request for proposal, we sat down with Levvel and together we assessed what the ideal solution would be for this project and what conditions the pumps had to meet. The shape and dimensions of the pumps are important, but issues such as reliability, energy consumption, fish safety and maintenance costs are also important."

In one year, the time the tender phase lasted, the design for the pump station was developed. "In this, too, Flowserve has been closely involved. We are constantly thinking along with Levvel about inflow and outflow structures and looking over their shoulder at the progress. In the case of the pump design, it's exactly the other way around, with Flowserve leading the way and Levvel looking over our shoulder. A good cooperation, which is paying off," Waterink said. "The six pumps are a very important part of the overall design, in which nothing is left to chance."

Flowserve has its own Test Center in Etten-Leur.

Customization pur sang

The pump design that Flowserve is working hard on is highly specialized custom work. "Admittedly, the basic principle has been known for 75 years, but added requirements such as fish safety are new," he says. Unique are the dimensions of the pump itself and the overall project. For me, in the 25 years I've been working at Flowserve, this is the largest pump project I've had the privilege of supervising."

Looking at the technical aspects, we are talking about an impeller diameter of 4.6 meters per pump. "The pump will have a two-bladed impeller, which has a rotation speed between 27 and 58 rpm. The fact that these are two impellers, at this relatively low speed, makes the pump fish safe," Waterink continued. "The rotor unit is partly in the concrete section, partly in the steel casing. The height of the pump unit will be between 12 and 13 meters. In terms of weight, you can think of about 120 tons per pump unit."

With such dimensions and weights, we can imagine there will be a tough logistical challenge ahead? "That's right. The first challenge is getting the pump units to their destination, the second will be hoisting the pump units in and the third will be precise positioning. Transportation on site and hoisting will be handled by Levvel, the alignment and connection will be done by Flowserve."

Enough capacity for the future

The capacity per pump is nominally 39.17 cubic meters of water per second. "That brings us to the requested number of 235 cubic meters of water per second with the six pumps provided," he said.

The pump motors draw 1950 kW each and are equipped with permanent magnets. This makes the pumps maintenance-friendly and reliable. "To power the motors, we will soon be using 690 Volts of power current. The efficiency of the pumps, with an efficiency of 70%, can safely be called high. That is unprecedented for this application with its associated design requirements," Waterink outlines. The energy consumed by the pumps is compensated on the Afsluitdijk itself by means of solar energy.

From engineering to delivery

"We are now in the engineering phase. From the first quarter of 2020 to the first quarter of 2021, we will produce. Delivery of the pumps is scheduled in April and June 2021, in two deliveries of three pumps," lists Waterink.

What about connection and control after everything is assembled? "Flowserve delivers all the necessary information regarding connection and control neatly to Levvel.

You may think of that document as a manual, containing everything about starting, stopping, the use itself et cetera. Levvel will design the integral operating system based on that."

Nothing can yet be said about the maintenance of the pumps after completion: "We are still discussing this." For Bert Waterink, the Afsluitdijk project is a dream come true. "I am a pump man at heart. This project is the water project within Europe from the past 25 years to the next 25 years. The renovated Afsluitdijk will ensure that we can keep our feet dry in the years to come. Together we are writing history and I am more than proud to be able to make my contribution."

Reliable and efficient pumping systems are indispensable for water management. Flowserve is a multinational and global leader in various sectors in pumps and associated shaft seals.

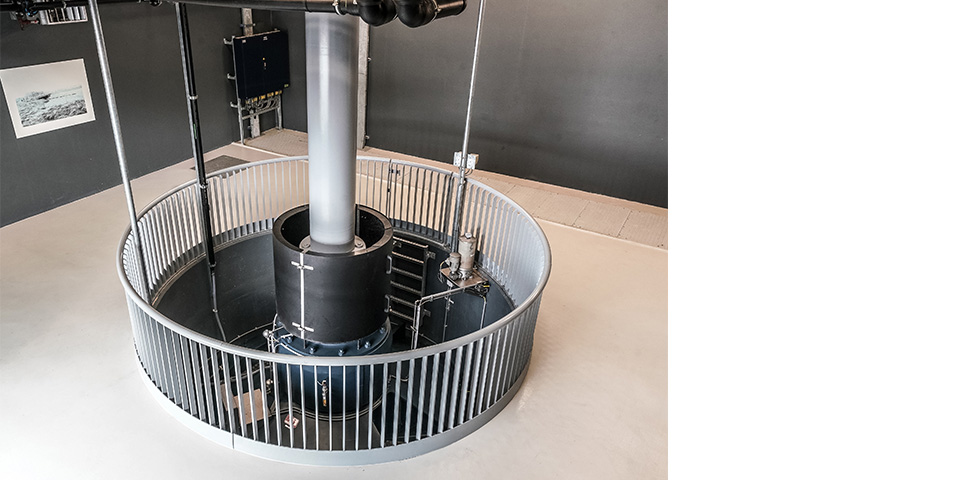

Top view of the Back-pull out of the BCV360 pump which is connected via a spacer coupling to a directly driven electric motor.

In 1997, Flowserve acquired STORK engineered pumps in Hengelo, and with them the more than 100 years of rich history of knowledge and expertise and a large number of pump types, such as BSV, BCV, BVOP, VOP, OVOP, SHG and OPH, which are commonly found in Dutch pumping stations.

Drive the BCV360 pump by a 1 MW slow rotating motor making 60 rpm .

Flowserve's head office in the Netherlands is located in Etten-Leur. With its 650 employees including ± 100 engineers, this Dutch branch is Flowserve's largest branch worldwide.

Flowserve is engaged in overhauling, maintaining and upgrading existing pumps, as well as developing new fish-safe pumps. One example is their CVPS-F, a concrete volute casing pump that will now be used in the renovated Afsluitdijk.

Katwijk pumping station, the pumps were increased in capacity and the existing diesel engines with gearboxes were replaced with pumps driven directly by electric motors.

Like no other, Flowserve has knowledge of the hydraulic and mechanical design aspects of pumps and pumping systems. In close cooperation with the client or civil contractor, the best solution for the customer is determined.