Increased focus on mechanical engineering in civil structures

The investment for the drive of a lock, bridge, dam, pumping station or weir is often in stark contrast to that of the overall civil construction. While the greatest risk of failure often lies in the electromechanical and hydraulic drives. And according to Louis Wouters of Wouters Werktuigbouw, this is far from always considered. "A lock gate or weir that fails because a defective mechanical or hydraulic part is not in stock can have major consequences."

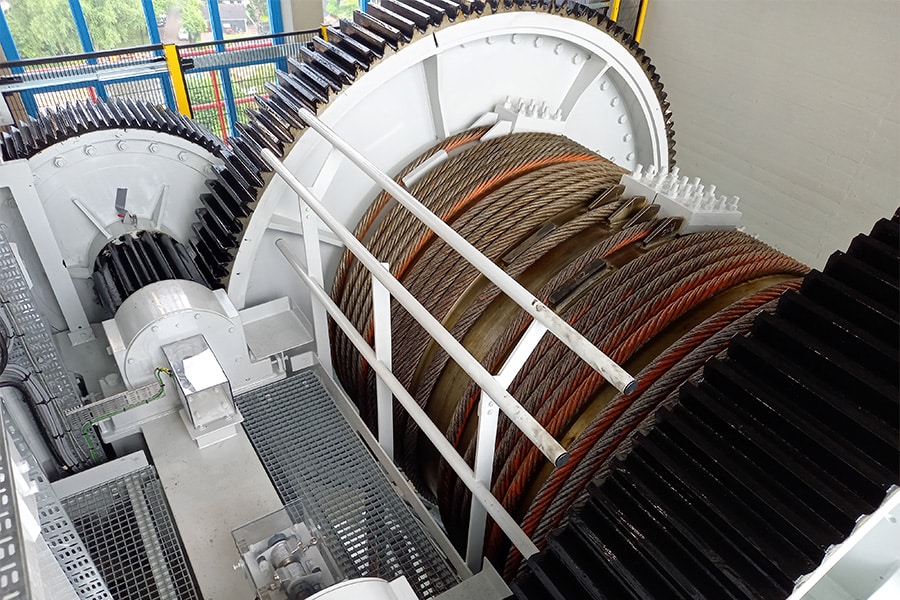

Wouters Mechanical Engineering feels like a fish out of water in "wet" infrastructure. "We give advice on new construction and renovation of hydraulic objects, but also provide periodic inspections. Our expertise lies particularly in the mechanical engineering field, in mechanics and hydraulics," says Louis. Based on inspections, we test existing objects against calibrated standards and requirements, for example. This results in a certain condition score. If this is below the limit value, then even (structural) safety may be at stake and it is important to take action quickly. In this way, we also think along in the design of new construction projects and, if required, support in making the right mechanical engineering choices so that they do what they are supposed to do."

Water Law

Critical objects, such as flood defenses, are failure probability controlled. "This is calculated mathematically and all technical components affect this. Whereas previously 1 in 200 times failure for the Hollandsche IJssel flood barrier, for example, was allowed, with the changes in the Water Act it is now 1 in 1,500 times for 2030. That's a significant reduction in the probability of failure. And within now and twenty-five years it will even go to 1 in 2,000 failures. So then nothing should really go wrong. With common sense and common sense you can tackle many of these potential problems," Louis assures. "First of all, make sure that you perform good preventive maintenance, inspections and measurements are an important part of this, and that includes critical parts management. You can do wonderful mathematical sums, but it's also important to keep thinking in practice. For example, we were recently involved in a defect on an object. It turned out that a small technical component had failed. And you guessed it, that wasn't in stock. Moral of the story, also make sure that spare parts management is in order."

Shocking

In hydraulic engineering, the financial focus is mainly on civil structures, Louis also knows. "With a relatively small effort on our part, risks involving large sums of money are sometimes tackled and consequential costs that can be many times higher. You don't want to know what it costs if a critical object is found to be unsafe or can no longer fulfill its function." Therefore, according to Louis, it is imperative to take preventive action in order to tackle potential risks in advance. "For example, we were recently asked to inspect a work of art asking whether it could remain up and running for another four years until major maintenance. The findings were quite shocking. Immediate action was needed. And that, unfortunately, is no exception these days. It happens quite frequently that we have to recommend temporary measures to keep works of art safely in the air."

The beauty of Dutch hydraulic engineering is the great diversity of objects, Louis believes. "From objects built just after World War II with old (and reliable) techniques to objects with state-of-the-art technology equipped with lots of electronics and proportionally controlled hydraulic installations. With over 30 years of experience in this sector, we are uniquely qualified to assist clients and contractors to ensure the safe and reliable operation of these objects. And that starts at the design stage with attention to the mechanical engineering aspect."