Market leader in drainage solutions TBS-SVA offers climate-adaptive product range

After a soaking wet winter and spring, it remains to be seen what summer will bring. What we do know is that the weather is becoming more erratic due to climate change. "We are dealing with more frequent rainfall with increased intensity. We are also experiencing prolonged droughts, low groundwater levels and inner-city heat stress," says Willy Bruckers, commercial director of TBS-SVA GROUP. "With our climate-adaptive product range, we can really make a difference."

Water drainage, buffering and infiltration

TBS-SVA, the market leader in drainage solutions, has launched several innovative products since the merger in 2020. "Where we were previously concerned with draining water quickly, we now do so responsibly and with care," Willy continued. "We ensure that the water that ends up in public spaces or ground or surface water is as clean as possible. In addition, we have devised new forms of water buffering, drainage and infiltration with greening and cooling of the downtown as our goal." Examples include the Cyclone Filter Well Gully, the Cool City Draining Gutter and the Mini Rain Garden.

Continually developing

"Because the world and the climate keep changing, we also keep constantly developing," Willy says. "This is how we arrived at the question: where does the remaining water go, how is it done now and what can we do better than what is already on the market today? In doing so, of course, we don't lose sight of our mission and we want water to go into the soil as clean as possible."

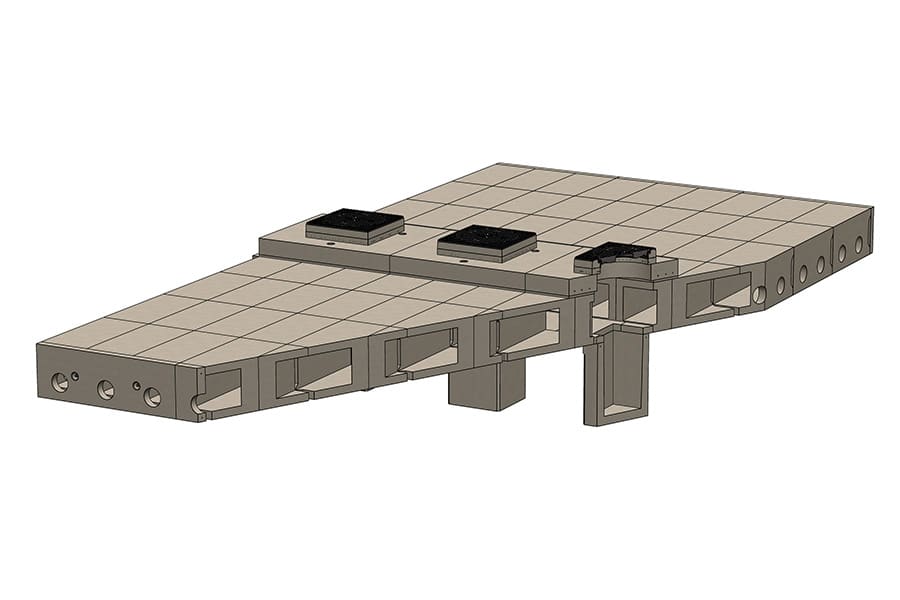

Infiltration system made of concrete

TBS-SVA has developed a new product: the retention Gully Box System, made of concrete. This marks an important step toward infiltration as high as possible, where load capacity is an important requirement. "Many infiltration systems are made of plastic and have to be placed deep in the ground to prevent overloading by traffic," Willy explains. "This involves higher excavation costs and is difficult in places with high water levels."

Sustainability

TBS-SVA's concrete retention Gully Box System has several advantages. "Because the Gully Box can be placed relatively short under the pavement, it not only saves excavation costs, but it also means the product has little to no contact with groundwater," Willy said. "This allows the collected water to spread more easily in the subsoil. Another important advantage is that concrete is many times more sustainable: not only is it produced with 33% recycled raw materials, but it is also 100% recyclable end-of-life."

Traffic tax

Willy is convinced that it will particularly appeal to clients that the robust concrete product can take a beating. To indicate this even better, he mentions the corresponding numbers: "For Traffic Class 30, light traffic, the Gully Box must be 23 cm under the pavement, for Traffic Class 45, medium traffic, it is 29 cm and for Traffic Class 60, heavy traffic, it is 35 cm."

Good accessibility

When asked about maintenance of the system, Willy says the Gully Box is easily accessible through manhole covers. "It's constructed so that under the manhole cover the structure is slightly lowered, allowing the water to drain into the dirt collection pits, which are for easy cleaning of the system. Matter of lid open and you can get into that pit. The Gully Box can also be fitted with a grate lid or vent lid, because the air has to be able to leave when the system fills with water." Willy emphasizes that there won't be as much contaminated water in it when it's done right. "Especially when you combine the system with our Cool City Draining channel or the Cyclone filter well gully."

Awareness

TBS-SVA developed these solutions all with the idea of keeping systems clean, lasting as long as possible and, above all, allowing as little pollution as possible to run into groundwater. "People are becoming more and more aware of this problem," Willy notes. "A few years ago, for example at a trade show, if I started talking about how much polluted rainwater and even microplastics are disappearing into the soil, you'd see people react with surprise: 'rainwater isn't that dirty, is it?' By now we know better. In addition, the economic challenge also plays a role, as many traditional, expensive systems clog up within a few years and stop working after a while. While in fact, with our sustainable systems you don't have to make a mega investment to stop the dirt. Moreover, maintaining them is easy to do in the way people are used to and that way the systems last considerably longer."

Microsite on climate adaptation

To spread the message further, TBS-SVA is working on a microsite about climate adaptation and their climate adaptive products. "It is expected to be launched before the start of the construction vacations, so keep an eye on our website as the microsite will soon be accessible from there," Willy concluded.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met TBS-SVA GROUP.

Contact opnemen

Contact opnemen