E-technology: power and data for the renovated Afsluitdijk

In its renovated form, the Afsluitdijk will contain even more technology than it does now. Among other things, additional pumping stations, a Fish Migration Gate, two pumping stations with a total of six colossal pumps and two floodgates will be added to the already existing mechanical and hydraulic parts. Things that require power supply, that need to be controlled and, not unimportantly, monitored.

Croonwolter&dros is providing the E-technical part around the renovation of the Afsluitdijk. Jos Dekker is responsible for on-site project management. We talk to him about the many facets involved in the E-technical part.

Logical Job Fulfillers

"Croonwolter&dros takes care of the E-technical part, including operation and control, except for the LFVs: the Logical Function Fillers," Dekker opens the conversation. "A sub-installation with its local operation and control is called an LFV. The set of LFVs forms the lower abstraction layer in the plant. The LFVs include a defined control interface, a control program and a local network that connects to the sub-installations. Each supplier of technology to the Afsluitdijk works within an LFV specified by Rijkswaterstaat and is responsible for meeting the requirements set."

When the 20 kV enters the procurement station, it is distributed to the floodgate, the pump buildings and the new and old pumping stations.

The electrical installation in a nutshell

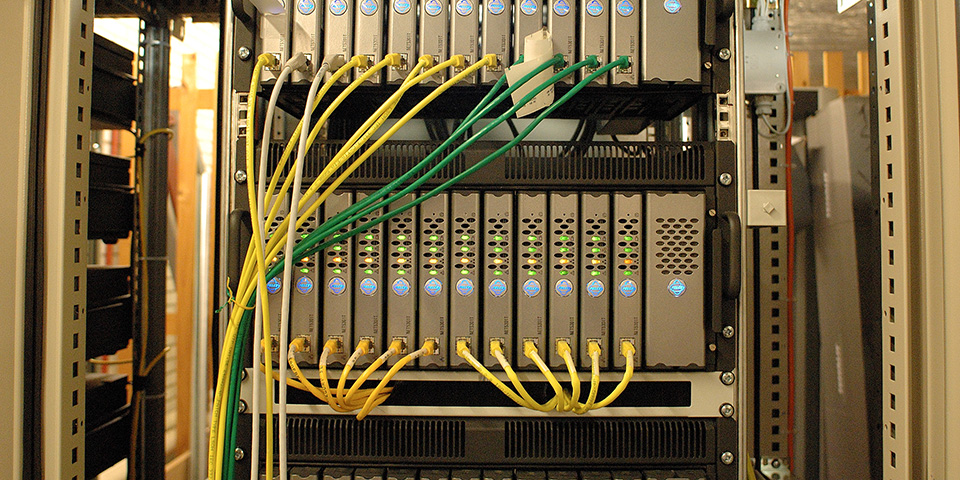

Dekker takes us along all the components that together will form the electrical installation of the Afsluitdijk: "There must be a control point for the control, networks must be realized for data, with a link to Rijkswaterstaat. Cameras are connected to this network, because the control stations must have a remote view of what is happening. It must also be possible to communicate from the control point with both the skipper and maintenance personnel. An example of this application is the communication that must take place at the location of the floodgate at Den Oever. This sits in front of the existing lock. Something may need to be communicated when operating this facility, in which case you need a voice-audio connection. This can be done via intercom as well as speakers."

In Den Oever, there will be a control point for the floodgate, for the pump pumping stations and the old and new pumping equipment. "That will all be brought together at one operating point at the current location," Dekker continued. Another important issue with security in mind is the access control system. "Intended to be used by employees, people from the Department of Public Works and other parties who need to be there. Through a badge system with privileges linked to it, physical access can be obtained, at a very high security level. The burglar alarm system is also linked to this." Speaking of security, the fire alarm system (BMI) naturally comes up. Dekker: "The BMI including the PVE (Program of Requirements) is also part of the electrical installation. It is monitored in a hermetically sealed room, a PAC control room in Alkmaar. Trained personnel work there, trained to act correctly in alarm and emergency situations. Both fire and burglary alarms arrive at the PAC control room."

The floodgate requires 630 KVA, the pump building 1600 KVA, the sluice objects 2 x 1000 KVA and the other buildings 1000 KVA each.

The right nutrition

In order to supply power to the electrical system and keep it energized in any situation, special cables are being laid. "For Den Oever, 20 MVA is needed, using 20 kV supplied via cables from Middenmeer. That falls under the scope of Liander. Redundancy will be achieved by a backup power supply from Anna Paulowna. The procurement station is being built entirely by Croonwolter&dros and will include server rooms and maintenance areas."

"When the 20 kV enters the procurement station, it is distributed to the floodgate, the pump buildings and the new and old sluice objects. The floodgate requires 630 KVA, the pump building 1600 KVA, the sluice objects 2 x 1000 KVA and the other buildings 1000 KVA each. In addition, each pump (6x) receives a 20 kV power supply with 2.4 MVA Flowserve puts its own transformer between the connection and the pumps."

Responsible for all the hydraulics needed is Hycom. "We are saying goodbye to motor-operated slides, everything will be hydraulic. The Programmable Logic Controllers (PLCs) supplied by Hycom are linked by us for control, we give the commands to the systems and receive feedback. This is done from the software, the 3B system: operation, control and monitoring."

In conclusion, Dekker says, "No fewer than four Croonwolter&dros divisions are active within this project. Infra, for project management and installing the installations on site, TAI for the software, GBBS for the building management system and Utility for the fire alarm systems. In addition, our High Voltage, Panel Building and Survey and Inspection specialties are involved in this project."

There must be a control site for the controls, networks must be established for data, with linkage to the Department of Public Works.