Speed up with vision at dike reinforcement Havendijk Den Helder

On the Havendijk in Den Helder, a special dike reinforcement project is underway. It is a relatively short dike section, but the task is challenging. Whereas a traditional dike reinforcement project for a primary flood defense system can easily take eight years from exploration to completion, it can be done here on schedule in just five years.

The harbor dike in Den Helder no longer meets safety standards and is therefore included in the Flood Protection Program (HWBP). Especially the middle part of the trajectory has urgency in terms of water safety. The urgency is caused because the dike no longer meets the outward stability and the sheet piling on this section is also in poor condition. The project area around the Havendijk is a dynamic area where different interests come together. The levee is opposite the Royal Navy site, close to residential areas, and directly adjacent to existing port area with planned expansions. Traditional phasing with years of research and design steps was not an option. Hoogheemraadschap Hollands Noorderkwartier decided to work on the dike reinforcement at an accelerated pace, with the exploration to be completed in one year. A challenge that was awarded to the combination Iv & TAUW. Together with Hoogheemraadschap Hollands Noorderkwartier, a project team was assembled in which the three parties all contributed their own expertise.

A pace that does justice to the urgency

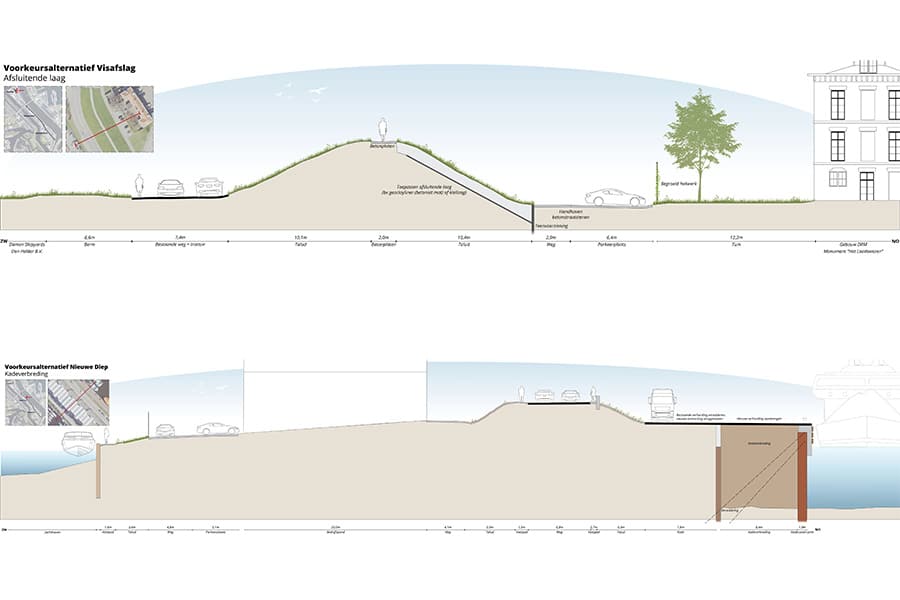

Although the Port Dike project is relatively limited in size (655 meters), the route has great technical variation. Each section of dike requires a specific approach. For example, on the north side of the section, near the Fish Auction, the dike consists of a soil barrier. There the revetment will be modified by excavating the existing top layer and applying a new, less permeable clay layer. This measure increases the stability of the dike without changing the original shape or appearance of the landscape. This solution is combined with a structure in the toe of the dike.

The middle section of the route represents the most technically demanding and challenging part. Here there is a heavily deteriorated dam wall construction, located directly along the harbor quay. The outside stability here is also no longer satisfactory. At the same time, there was a clear desire from Port of Den Helder (manager of the area) and the Municipality of Den Helder to expand the harbor area. Instead of two separate interventions, an integrated approach was chosen: the existing quay makes way for a new combi wall construction, built from heavy sheet piles with deep anchoring: robust enough to allow larger ships to moor safely. Moving the quay outward creates approximately 5,000 square meters of new land that can be used as work or storage space.

Integral approach? Gladly, but quickly

In this way, the dike is not only strengthened, but the project also directly adds value to the environment. In other projects, these kinds of opportunities often cause delays because decision-making or financing does not fit within the preferred planning of the dyke reinforcement. Within this project, this was deliberately managed by making the schedule the guiding principle. From the outset, the project team applied clear rules: opportunities are welcome, provided that initiators actively participate, arrange their financial contributions on time and record administrative agreements. The dike reinforcement does not wait. This approach ensured that the parties involved were sharp, cooperative and quick from the start. This made it possible to include the expansion of the port site in the project in a relatively short period of time. And that exploration phase in just one year? We succeeded!

The acceleration was not achieved by skipping steps, but by a fundamentally different approach to the work. The key lies in the way we work together. Instead of separate parties with separate responsibilities, the project team forms a tight unit where knowledge and expertise are paramount. In practical terms, this means: joint working days, shared schedules, trust, mutual respect and equality.

A role for sustainability

Sustainability has a central role in the design. An important focus is the reuse of materials released during the work. Think of clay, soil and existing structural parts such as sheet piling or concrete. Already during the exploratory phase, these materials will be considered for recycling or reuse within the project itself, for example as fill material or in the new dike revetment. It is also examined whether regional stakeholders, such as Port of Den Helder, Municipality of Den Helder or initiators of other infrastructure projects, can benefit from the released materials. This prevents unnecessary transport and waste streams, and contributes to a circular approach to the project. Sustainability is also taken seriously in the preparations for implementation: efforts are being made to use emission-free equipment as much as possible and smart phasing to limit transport movements.

A future-proof barrier and inspiring project

The preferred alternative has now been administratively decided. Over the next few years, the project team will work in the planning phase towards implementation: in 2026 the contract is scheduled to be awarded, with the aim of starting work outdoors in 2027. If everything goes according to plan, the dike will have been reinforced by the end of 2028 and will once again meet the standard. A journey from exploration to realization in just five years. That is lightning fast, especially for reinforcing a primary dike with different designs and different stakeholders around the dike. Project Havendijk shows that it is possible to accelerate the process without compromising the content. And once the dike is watertight again, what remains is a safe, future-proof dike and an approach from which other projects can draw inspiration.