From heavy supports to (design) elements in public spaces

Marsé Montage is a regular partner for many civil engineering companies in our country and in that capacity involved in a wide variety of projects. The company has been owned by Job Hester for three years and under his leadership it has grown into a major player within the sector. Job also has big plans for the future.

The past year has been extremely successful for Marsé Montage. "We have been active on a lot of different types of projects," Job says with appropriate pride. "We only see our client base growing. Existing customers have stayed and we have gained new clients. That makes us extremely satisfied." According to Job, it is mainly due to the tight organization and the fact that Marsé Montage is also extensively certified. "We have our certifications all neatly in order, are allowed to perform welding up to and including NEN-EN 1090 execution class 3 and last year we worked a lot under the ROK 1.4, an additional requirement from the Department of Public Works. That means we can take on challenging welding jobs."

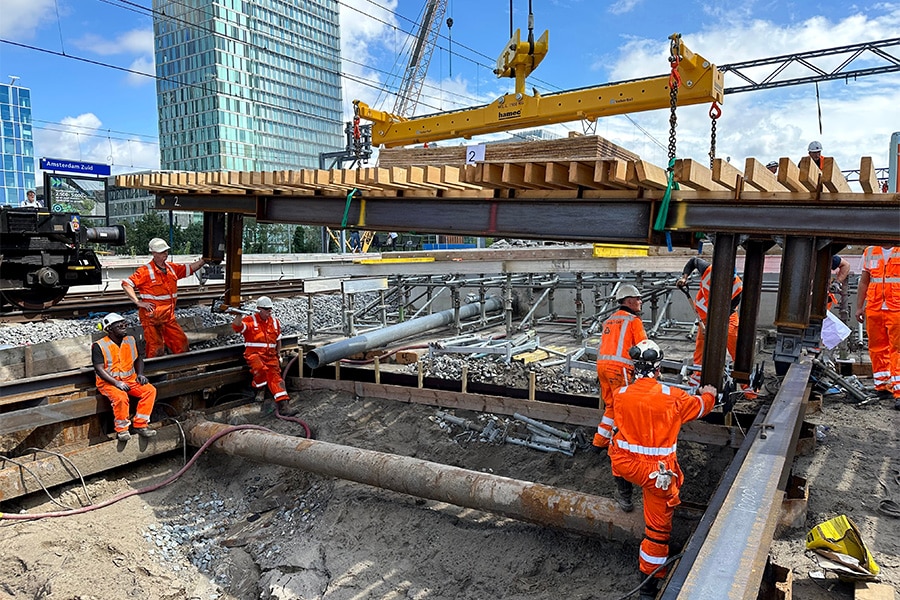

From the Selective Withdrawal to the Zuidasdok

Since the summer of 2022, Marsé Montage has been working almost continuously on the Selective Withdrawal at the sea lock in IJmuiden. Among other things, all the outrigger frames, the anchoring structures and the purlin work come from the quiver of the specialist in steel auxiliary structures. "All welding in accordance with NEN-EN 1090 execution class 3 and ROK 1.4," assures Job. "Furthermore, we have been busy on the Zuidasdok project. For example, we made and assembled a steel platform deck 80 meters long and 12 meters wide, as well as some 200 meters of purlins. We also supplied the necessary purlin work near Stompetoren for the reconstruction of the N243, as well as some 200 meters of sheet piling in the form of steel U-profiles. We are currently making a large reinforcement mold for the widening of the A9 between Badhoevedorp and Holendrecht." In addition to these large projects, Marsé Montage does not shy away from smaller projects. Although, the thirteen corten steel flower boxes for KWS on the Eerste Van Swindenstraat in Amsterdam are not that small either with one even measuring 9 by 8 meters."

Fast and flexible

So our work is extremely diverse and ranges from large heavy supports to beautiful corten steel flower boxes, and everything in between. And that predominantly in steel with occasional forays into stainless steel and aluminum, Job summarizes. "Last year we updated our machinery and invested, among other things, in a new bending bench, on which we can set plates up to 3 meters wide and 15 mm thick, and a new saw with roller tracks. Investments that are necessary to meet the growing needs of our customers. This is also directly our strength. We can complete very large projects quickly and flexibly with little information. Thanks also to our loyal club of twelve professionals and a flexible shell of another ten to fifteen people." Job therefore looks forward to 2024 with great confidence and already has many interesting projects in mind.