Expertise from Fugro puts money to work

Various challenges in dike reinforcement Wolferen-Sprok cleverly addressed

In the middle of last year, the go-ahead was given to reinforce the northern Waal dike between Wolferen (Overbetuwe) and Sprok (Nijmegen). Commissioned by the Rivierenland Water Board, construction consortium De Betuwse Waard - consisting of Ploegam, GMB and Dura Vermeer - will strengthen the 15-kilometer stretch over the next few years.

Themes involved in the project include safety, sustainability, area development and climate adaptation. For the main technical challenges, the help of Fugro was enlisted. We speak with Werner Halter, principal consultant at Geo-data specialist Fugro and with Marijn Hop, hydraulic engineering consultant at Fugro, about the studies and solutions the company provided for this project.

Piping is a problem along almost the entire route

Marijn opens the talk, "The main technical challenges on this project are effectively solving the piping problem, the limited space available for applying reinforcement measures, making the dike flood-proof and working within the strict Natura 2000 requirements." What exactly is meant by "piping"? Werner explains: "Piping can occur during high water situations. Due to a large difference in water level in front of and behind the dike, large pressure differences can occur. As a result, water may flow under the dike and then emerge again behind it. The result is the creation of a "well," a place where seepage water rises. When the high water and the difference in water pressure persist, water can continue to flow through the sand layer under the dike. If sand particles are carried along, a channel (pipe) may form under the dike. If this occurs over a long period of time, then erosion can eventually cause the dike to collapse."

Marijn: "At Wolferen-Sprok, approximately 90% of the dike section has a problem with piping. Fugro has used HPT-AMPT®(Aquisense™) soundings - widely used- mapped the variation in horizontal and vertical permeability. In addition, we mapped the clay layer so that we could include the resistance of the foreland. This gave us answers to the question of where the 'pipe' grows. Normally, only a limited length of the foreland is included. However, we looked with Deltares to tighten that up. That resulted in an approach that benefits 'dike country'." As a result of the additional research, piping solutions were no longer needed for part of the project. For the locations where this was still necessary, Fugro proposed a solution with heavescherms and optimized their design. "Part of these screens (sheet pile walls) will be made of plastic and part of them of steel, depending on the stability task and soil structure in situ," Marijn said.

Werner adds, "It is becoming more common to use HPT-AMPT technology to measure subsurface permeability to more accurately determine the piping task."

Working in limited space

The homes, nature and other interests along the dike provided very limited space to work in. It was therefore important to make the reinforcements as compact as possible, to cause as little impact on the surroundings as possible. "Making the dikes much wider was therefore out of the question, work had to be done in the given, tight space. That's why the heavescherms are such an ideal solution," Werner explains. "Furthermore, it was important to spare the Natura 2000 area. No construction is allowed in the Natura 2000 floodplain, not too many trees must be uprooted, and construction must be phased to minimize disturbance to nature."

Marijn: "Priority 1 was a safe design, then we looked at the design in relation to fitting within all the rules and guidelines. The design was adjusted accordingly." Groundwater levels were also considered. Werner: "The sheet pile walls must not affect the groundwater levels. After all, nature must not be disrupted and foundations must not be damaged. This is why Fugro carried out extensive analyses of the effects of the proposed measures. In the exploratory phase, Deltares took part, and later we collaborated with Deltares to spare intersecting gas and water pipes."

OVERSLAVING the dike

"The problem of overburden occurs with all dikes," Marijn outlines. "Since 2017, dike design has focused on large overburden to reduce the crest height. That brought challenges over the past two years, for which solutions had to be found. Wolferen-Sprok is a typical clay dike, where 10 liters of water per second per meter of dike is allowed to spill over." Werner adds, "The dike needed limited elevation. The choice made: a less high and less wide dike, good for the landscape image. But the inner course of the dike must not erode because of the overburden. In the case of Wolferen-Sprok, we have to deal with trees, houses and driveways present right behind the dike, so we had to consider in detail what the consequences of the adjustments would be. The sand shoal present could blow away during overburden. The solution Fugro came up with was to apply erosion-resistant clay. By looking smartly at the required clay properties, we were able to reuse local clay. We looked at what was needed for each dike section, in detail."

Typical Fugro

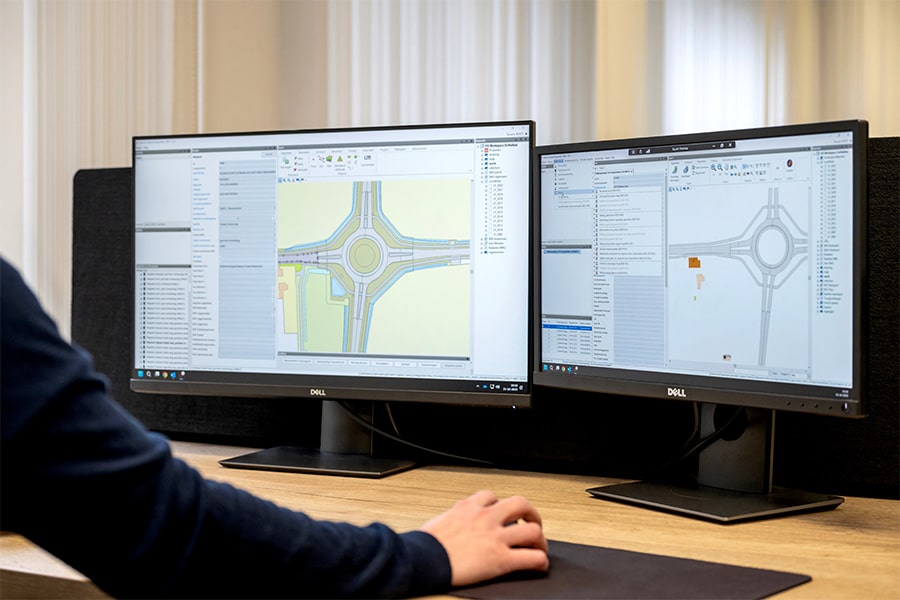

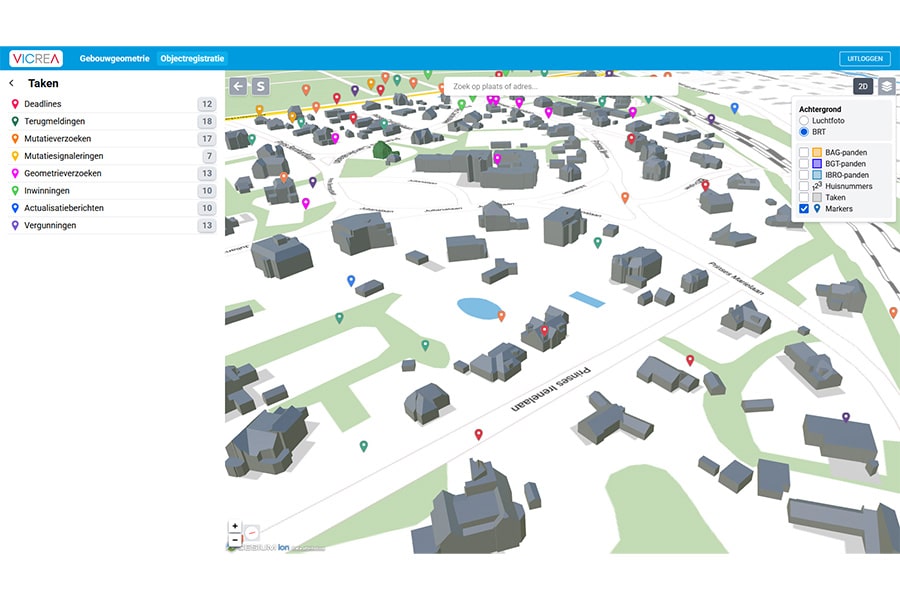

Fugro is known for its innovative techniques and solutions. "We simply leave nothing to chance," Marijn states. "In the planning phase, we were already in the construction team after the water board had determined the preferred design. A ground design with occasional structural elements. From there we created a plan design with far-reaching detailing. Fugro always thinks in optimizations: more nuance in rules, doing more research. We want to use the soil as effectively as possible, which can only be done by working as precisely as possible in the design. We use new software and new calculation methods to achieve this. For example, we have performed probabilistic analyses to show that costly reinforcement can be avoided, reinforcement that would normally have been applied preventively to prevent the dike from sliding during a storm. So we not only calculate what we need, but also what we don't need. Digitalization is therefore indispensable for sustainable and resistant work."

All of Fugro's in-house professional disciplines were therefore covered. Soil investigation, geophysics, geomonitoring, geodesy, laboratory and consultancy. Marijn continues: "As we speak, our lab technicians are still walking outside for soil testing, monitoring wells and monitoring. It's an 'ongoing process. Werner concludes, "A colleague gave a lecture internally at Fugro about this project. About 250 people have been working on it within Fugro, the client sees 10 walking around outside, the rest are working out of sight. So we can say that more than half of Fugro Netherlands' staff are involved in Wolferen-Sprok. Then you also understand the mutual enthusiasm for this beautiful project!"

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Fugro.

Contact opnemen

Contact opnemen