Strong partner in the foundation industry

For nearly 140 years Sterk BV has been working on foundation projects at home and abroad. Managing director Peter van Halteren: "We particularly like projects where we can add value for the customer through our knowledge and experience."

"Just a smarter design or a different working method can make the difference between a successful project or one full of headaches," says Robert, Peter's younger brother and member of the board of directors at the family business. "Strong is a broad specialist in this regard. Being able to offer multiple disciplines allows us to relieve our customers more and more."

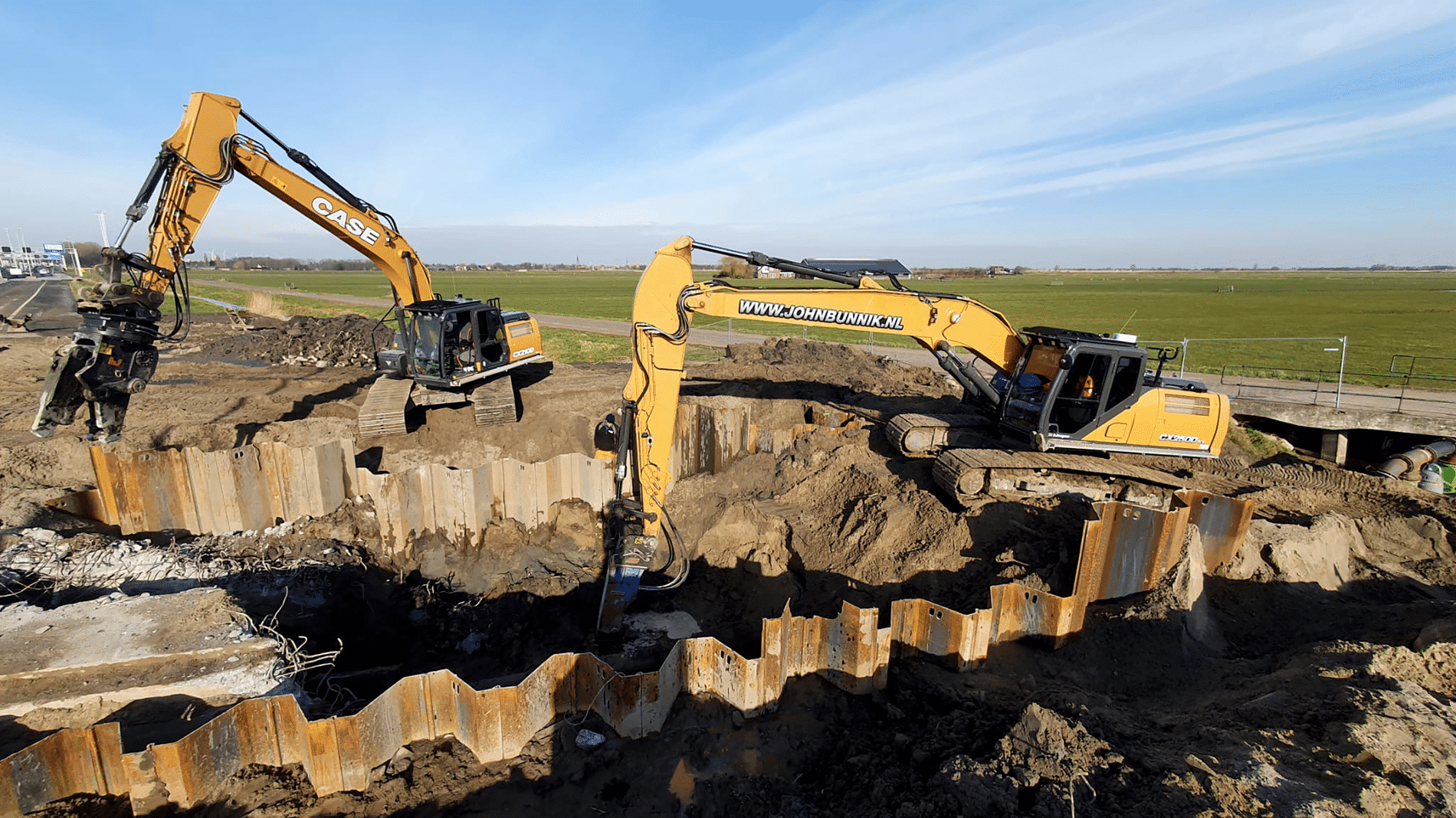

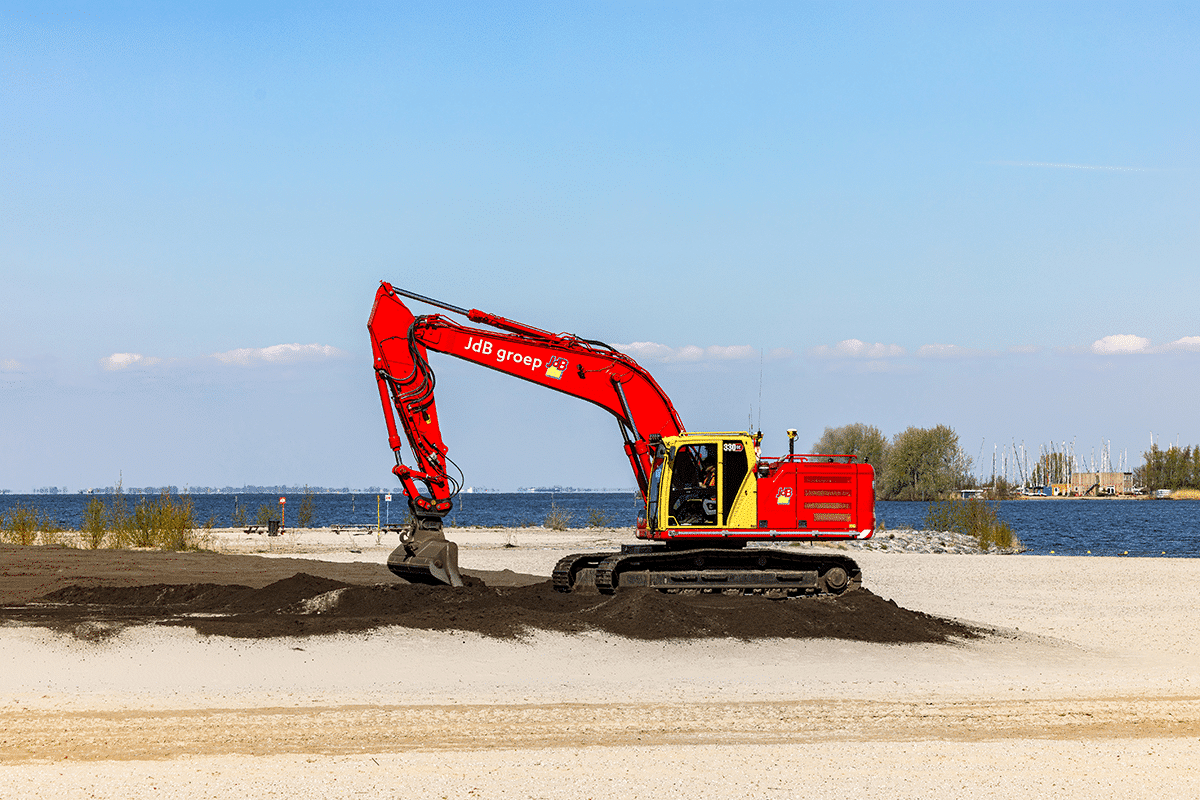

The Sterk family business was purchased in the mid-1990s by the Van Halteren family. Peter: "Originally, Sterk was a typical piling company. Under my father's leadership, new machines were purchased and operations were expanded." Now Sterk makes building piles, quay renovations and cooperates in large dike reinforcement projects, among other things. Thanks to committed and experienced employees and equipment developed in-house, Sterk can often perform work smartly, quickly and sustainably.

Prefabrication, transportation, installation

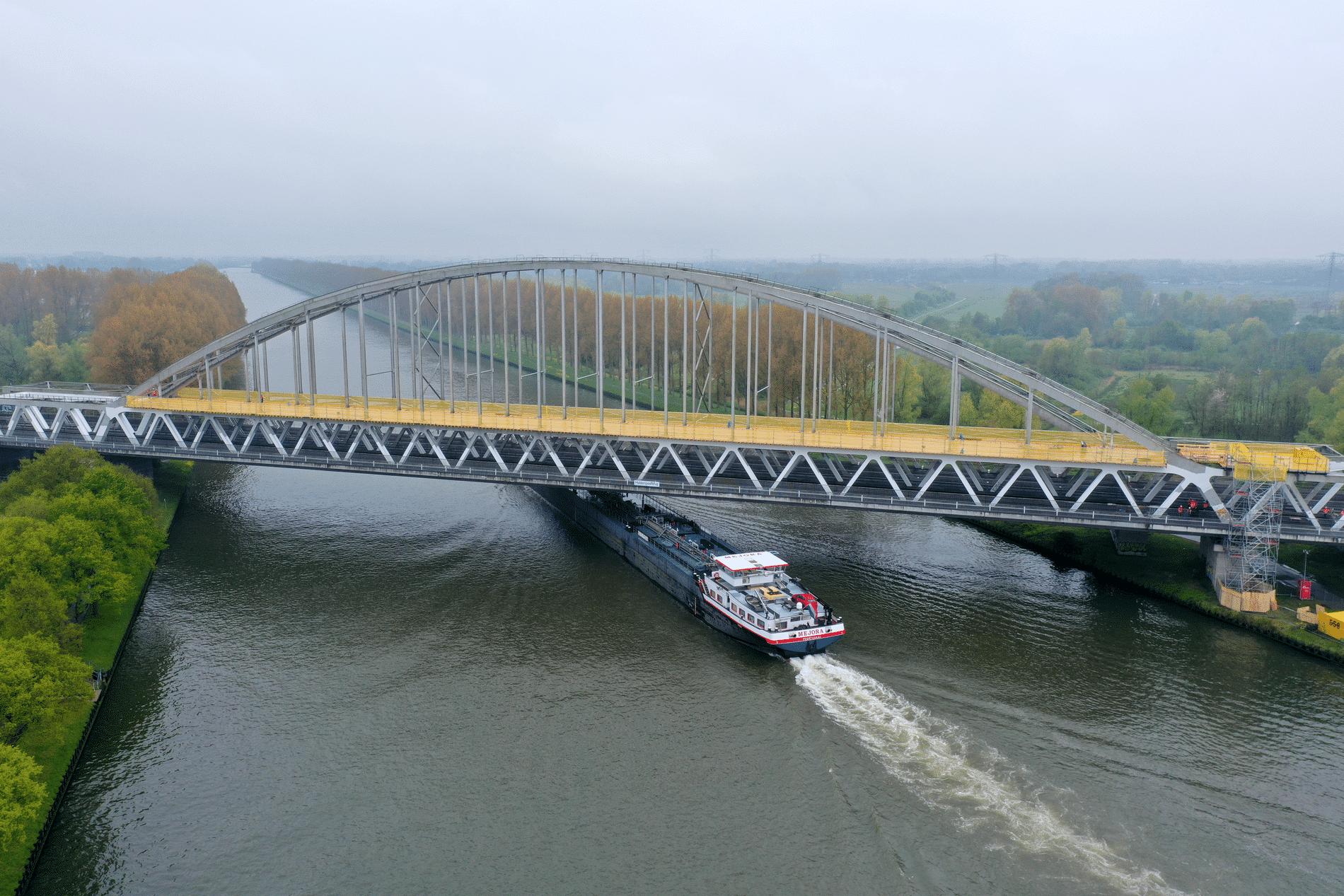

Many foundation projects require specialized welding and construction work. This is the field of Sterk Metaal working on the (prefab) fabrication of steel structures. Its waterfront location is optimal. Robert: "This allows us to transport large structures by water, with our own pontoons and tugs." Peter explains the importance of this. "In relative terms, water transport produces far fewer emissions than road transport and spares the road network."

Sustainability

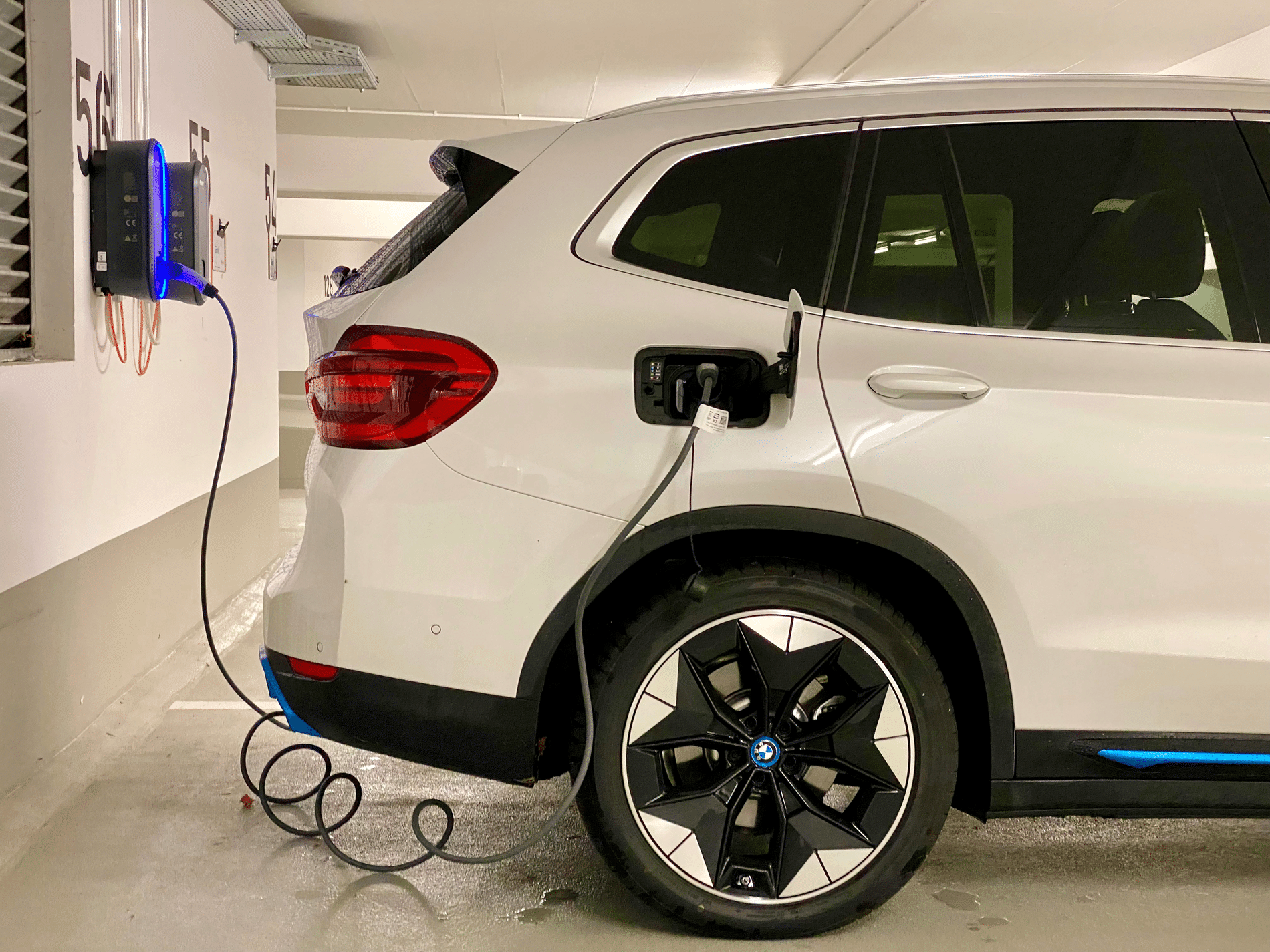

Robert: "The construction industry recognizes that things really have to change on the sustainability front. Strong is doing this in part by investing in cleaner machines and using smart software and advanced diesel fuel. 40% fuel reduction and up to 90% reduction in nitrogen emissions is simply already achievable." Peter: "In addition to purchasing new equipment, we also replace engines of existing cranes ourselves. Machines that could use an upgrade in terms of emissions and consumption, but are otherwise fine. After two previous successful engine changes, the installation of the third clean Stage V engine is already in the planning. This will be done by our own Technical Department. It's great that we have the knowledge for this in-house."

Safety

In addition to sustainability, safety is also very important to Strong. Robert: "Safety has always been important to us, but the recent certification for Step 3 of the safety ladder meant a lot to us. We have made safety a much more accessible and practical topic. And we continue to work on that. Of course, sometimes things still go wrong, but we discuss such matters with each other. That way we learn from them. Together you get further!"

Around the table early for smart solutions

Together you get further. For Strong, this holds true for other challenges as well. Be it sustainability, safety or innovation, for example. For example, Sterk began working with Mammoet Heavy Duty Pavements on an innovative solution for the foundation of crane stands on very soft subsoil. Robert: "We combined two different techniques to arrive at a solution with enormous potential. This was only possible by working together in openness and trust. This is also how we prefer to work with our customers. The earlier Strong sits around the table with a customer the greater the added value we can offer each other."