Sustainability, digitization and innovation at Dura Vermeer

His position is a special one, one that did not exist a few years ago. 'BIM director,' it says on the business card of Koen Verbruggen, who works at Dura Vermeer. "My department has existed for several years now and contributes to Dura Vermeer's three innovation ambitions," Koen explains. "Those are Sustainability, Digitalization and Innovation."

Cooperation in earthworks

"For earthworks, we work with Infrakit," Koen explains. "Within a project, there are always several parties who need information and generate that information. Previously, this information was on separate drawings, which encouraged errors. By having everything in an up to date 3D model, everyone has the right information and what is offered is current. The work of my department is to get the digital data supplied to match." Infrakit came into the picture at Dura Vermeer when implementing regional projects. "By using Infrakit, we allowed executives, dimensional engineers and earthworkers to work together on these smaller projects. A great example is the use of picket piles, which used to be based on manual measuring, but is now done based on GPS. This means that the contractor no longer has visual control over what is happening in the field. With Infrakit, he still gets all the insights he needs because we use it to visualize the stakeout points and 3D models on PC and tablet. So both the operator and the contractor benefit from having the right data available instantly."

Dennis adds: "That first contact came during the execution of a sewer reconstruction. The collaboration was so successful that Infrakit is now being used by Dura Vermeer on larger projects." Koen: "The first two larger projects with Infrakit are pilots for us, to see if we want to implement this working method integrally on all projects."

Wind Plan Blue

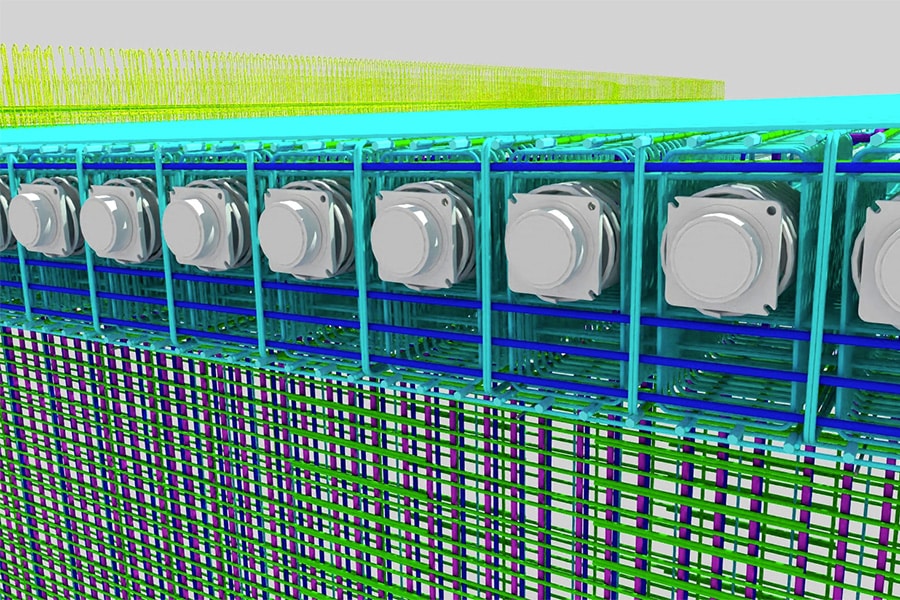

There will be 37 land-based wind turbines in Swifterbant, under the name "Windplanblauw. Dura Vermeer is responsible for designing the foundations for the wind turbines and the roads at the wind farm. "We're talking about about 20 km of park roads," Koen outlines. "The area consists of pasture with an area of about 20 km x 20 km. There are multiple landowners, with corresponding property boundaries. Our project ambition is to design everything in 3D, including the groundwork, to arrive at an integral coordination model in 3D. All earthwork is done using GPS and the contractor gets insight via Infrakit. We also do the infra inspections based on measurements instead of forms."

Dennis adds: "By running the GWW inspections based on measurements through Infrakit, you can visualize all the measurement data from measuring engineer and contractor in one place. That creates the possibility to create the delivery file during the process, of which the as-built data is part. Other documents include drawings, 3D models and photos taken."

Remote machine updates

At Windplanblauw, Infrakit is not linked to the equipment via 3D machine control, but it is at another Dura Vermeer wind farm. Koen explains: "Via Infrakit we remotely send 3D models to the machines. So nobody has to take a USB stick to all the equipment anymore. The contractor can also instruct the machine operator to record measuring points with his machine, so that the progress of the process becomes digitally visible in an accessible way."

Infrakit provides executives at Dura Vermeer with insight that previously only the dimensional engineer could provide. "Infrakit provides a reduction in failure costs, downtime on these projects and improves the cooperation between site manager and contractor," said Koen. "Infrakit provides the 'single source of truth' on these projects regarding GPS and earthwork in which data from in-house and external parties come together."