Moving toward dual-life ZOAB

The dream is over. That applies to LATEXFALT from Koudekerk aan den Rijn now that three developments to extend the service life of ZOAB asphalt on national roads are becoming a reality. Managing director Dr. Bert Jan Lommerts: "We can already guarantee that we can extend the service life of existing ZOAB roads by 5 years with our innovative emulsion technology products. In addition, research has shown that a second treatment 'sticks' to that for another 3 to 4 years. Furthermore, you can opt for ZOAB with better bitumen technology at the beginning of the process, which can also add another 5 years. Large parts of our dream to double the lifespan of ZOAB have come true. With in the slipstream of the extensive research soon to be recycling ZOAB highways into new high-quality ZOAB."

Twelve years ago, LATEXFALT deployed a new sustainability strategy, which, in part through scientific research, was to seek in particular to extend service life. Because that way damage to road surfaces and cars, the costs of maintenance and repair, amount of raw materials needed for replacement and inconvenience to road users could be significantly reduced. Lommerts explains: "We have known about ZOAB since 1972. The vast majority of national roads are now equipped with ZOAB. With all the advantages in terms of water drainage and noise reduction. Everyone knows the advantages. But also the disadvantages. Especially the porosity of the top layer is subject to erosion by road traffic and frost/thaw effects. This has to do with the aging of the bitumen used, which hardens and can less adequately bind the stony material. For us, the key question was whether we could develop a rejuvenation mechanism. A system where the bitumen could perform its function longer. A kind of Vichy or Nivea rejuvenation cream for ZOAB."

Asphalt Dermatology

Lommerts speaks more often of "asphalt dermatology," by analogy with rejuvenating human skin. The management took things seriously in development. Some ten years ago, the first chemical researchers were recruited, including Irina Cotiuga from Romania and Sayeda Nowrozon Nahar from Bangladesh, who began their studies in the Netherlands at TU Delft and TU Eindhoven, while at the same time dedicating themselves to research and development at LATEXFALT. Lommerts: "They have obtained their academic degrees and are renowned scientists, who, among other things, have been able to understand the aging process of bitumen. They have done this in cooperation with various universities. They have thus helped lay the foundation for our three roadmaps: sustainable bitumen through new bitumen technology, life extension with Modimuls ZV and Modiseal ZX technology and recycling via rejuvenating technology when milling asphalt is reused. Thus, the cycle is closed and you are on the way to optimum sustainability within the life cycle."

Everyone at the table

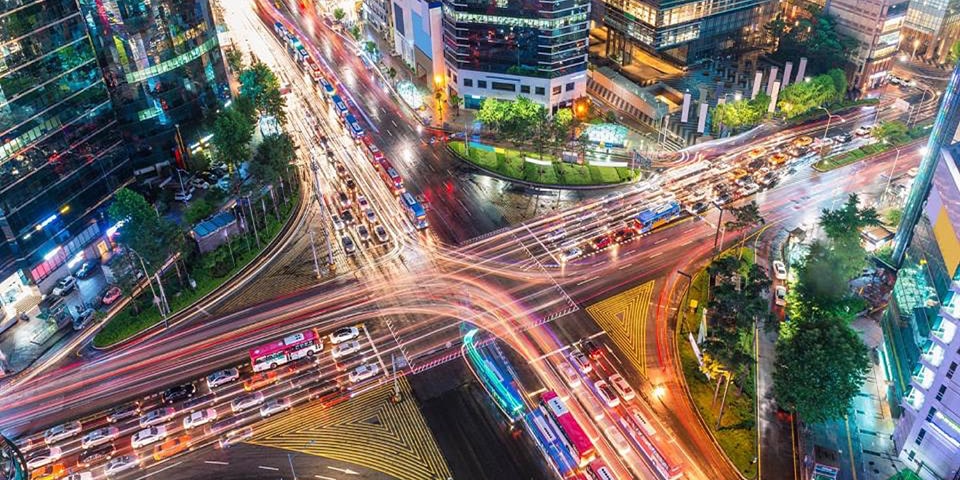

Lommerts points to the broad playing field with the oil industry, bitumen and asphalt producers, refiners such as his own company, the executing parties and the clients, with the Department of Public Works as the client for the national highways. "We did not sit in our laboratory, but participated in development projects together with different parties. All stakeholders are at the table. We have shared research findings, conducted trials together, analyzed results, in short, we have done a lot to gain trust in the market for these innovations. This is not hot air, this is concrete sustainability for 5,500 km of ZOAB national roads in the Netherlands."

In this regard, LATEXFALT is certainly being heard by the Department of Public Works and Public Works and contractors entering into contracts with a maintenance component. "As far as life extension with a first emulsion layer is concerned, we have already carried out several projects. The technique has proven itself in practice. The results also fit perfectly with the new methodology of the Department of Public Works to measure stone loss from ZOAB. Our treatment shows that loss is greatly reduced. We also guarantee the result of this treatment. With the other roadmaps of bitumen technology and 100% recycling, we are close to reality; further development is needed there to be able to give guarantees. But we are close. I personally do see that in a few years we will be able to guarantee that lifetime doubling."

The technique has proven itself in practice.

Validated technology

With life extension via emulsion technology, the ZOAB construction remains nicely open after the round of the sprayer. The pores do not close up. "Compare it to sunscreen that soaks into the skin. The effectiveness of five years or more of additional life extension has been demonstrated and this technology has now been validated.

Bert Jan Lommerts concludes, "I do still have a dream: that in 25 years we will have highways composed with the best bitumen products for high initial quality, which can be 'rejuvenated' a few times in their life cycle and, at the end of their cycle, can fully serve as raw material for new roads. For that, all parties still have some steps to take, but we are closer than ever."