Non-destructive soil testing prevents unnecessarily high costs

Every year, more than 25 million euros are spent on repairing damage to the cable network due to excavation damage. By performing a non-destructive soil survey in advance using a ground penetrating radar system, these unnecessarily high costs can be avoided, as well as the inconvenience to the surrounding area. Preventing excavation damage is therefore one of euroradar's main spearheads. But a ground radar system is capable of much more.

euroradar focuses mainly on detecting soil foreign material, such as cables and pipes and unexploded ordnance. "Ground penetrating radar is also excellent for mapping the soil structure, we can detect old foundations or other structures in the soil, and leaks or contaminants can be mapped," says Frank Barink of euroradar. "And all without digging. Depending on the soil conditions, we visualize objects in the subsurface up to a depth of 12 meters to the nearest centimeter. In doing so, we use different (or a combination of) techniques, such as a magnetometer, ground radar, cable locator or a superconductor. The latter machine is a much cheaper, more efficient and faster alternative to a traditional sounding machine with all its limitations."

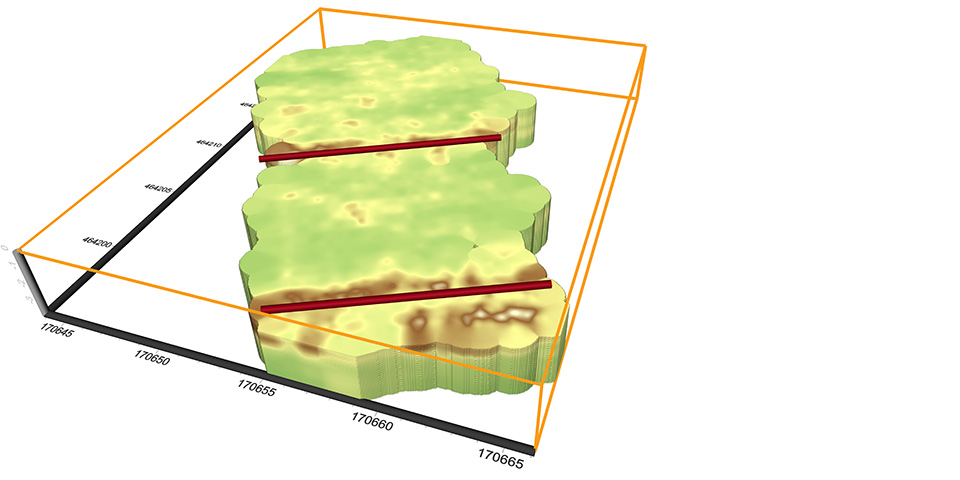

Ground Radar Reporting Cables and Pipelines.

No surprises

Excavation damage is among the biggest annoyances in the civil engineering industry and not infrequently causes considerable inconvenience to the surrounding area as well. "Performing a reliable soil survey can save a lot of suffering," Barink knows. "All good intentions notwithstanding, a KLIC report is not 100% exhaustive and orphan pipes are not visible. In every project one encounters one or more surprises that are not in KLIC. For example, during a recent project in Dordrecht, one stumbled upon an old city wall that no one had anticipated. Result: a huge delay and many unforeseen costs. A ground penetrating radar, on the other hand, clearly and precisely maps all underground infrastructure and other foreign obstacles. That way there are no surprises and they can be anticipated. Digging test trenches is thus also a thing of the past."

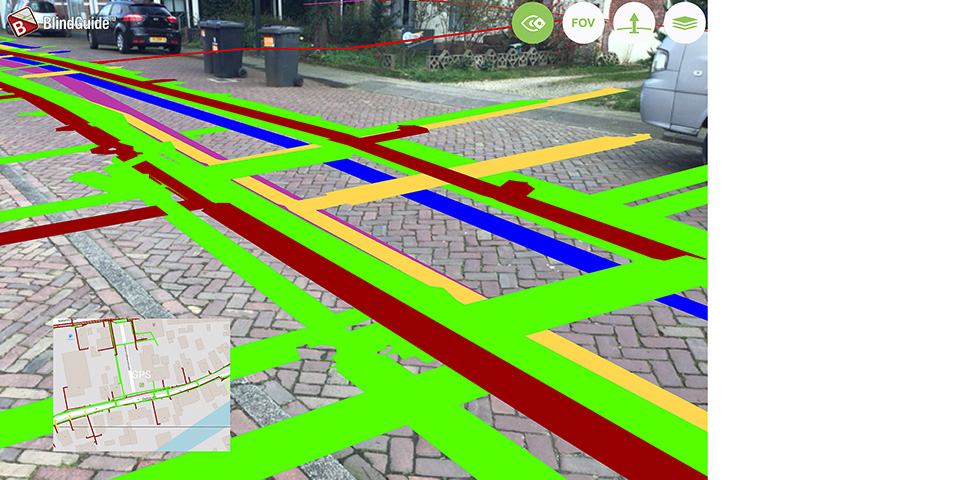

Blindguide Streetview.

Non-explosive ordnance

Barink gives another example where ground penetrating radar proves its added value. "For example, during a large-scale sewer replacement, we recently conducted non-destructive testing for unexploded World War II explosives, but in a different way. Instead of rigging up a costly explosives survey, we used ground penetrating radar to see where the soil had been disturbed after World War II. This allowed us to release areas quickly and eliminated the need for additional explosives testing. That saved tons in euros in this project alone. In yet another project, we performed a similar assignment, where we did stumble upon an explosive at a depth of 9 meters. By clearly mapping the contours of the object, it turned out that it was an already detonated explosive. Again, hundreds of thousands of euros in unnecessary excavation and salvage costs were saved."

Ground Radar Cables and Pipelines Display Edit.

euroradar transforms the scan data into clear drawings. "We deliver the data in any format, including BIM. The ground-based information can then be displayed on any device. In the future (before next summer), it will even be possible to load the data into the BlindGuide AR app, so that obstacles in the subsurface are projected onto the ground level. Ground penetrating radar is faster, cheaper and safer," Barink says in conclusion.