New Terneuzen Lock subjected to testing at scale

In our current age of digital solutions, we sometimes tend to think that everything can be done by computer par excellence. Everything can be simulated in the field of (hydraulic) construction as well, right? Many things can, but not everything. The operation of a lock complex is influenced by so many natural forces that a computer model can never capture all facets. As a country with far-reaching expertise in water management, we can count ourselves lucky to have test facilities such as those at Deltares in Delft.

Deltares is a Major Technological Institute in the field of water, subsurface and infrastructure. The institute focuses primarily on river deltas, coastal regions, river areas and offshore. Not surprisingly, an exact copy of the Nieuwe Sluis Terneuzen is currently being exposed to extensive testing at scale, right there in Delft. We speak with Wim Kortlever, senior hydraulic consultant at Rijkswaterstaat for the national Large Projects and Maintenance Service and involved with the Flemish Dutch Scheldt Commission (VNSC), about the testing procedure.

Already in the picture well before the procurement phase

"I have been working on the Nieuwe Sluis Terneuzen project since the planning phase, together with my Flemish colleagues within the VNSC organization," Kortlever opens the conversation. "During that phase, a number of explorations were already carried out to test the feasibility of the first design of the lock. Following that, we started preparing the contract for the construction of the New Lock with the same team from VNSC. During that contract preparation, the first design of the fill and empty system was already tested by Deltares in a scale model in two separate studies. We used the scale model of the New Sea Lock at IJmuiden for that purpose. Following the example of that new sea lock, the desire had arisen to fill and empty the lock via tubes with slides in the doors. This also seemed a feasible option for Terneuzen and is also the most economical compared to the more complex systems with sewers along the chute. Preliminary tests with door sleeves in the modified model of IJmuiden have shown conclusively that large water forces on the ship in this type of filling and emptying system can only be prevented by very much stretching the leveling times. The cause of this is twofold. At Terneuzen the situation is different. The gradient there is from about two meters above NAP on the canal to two meters below NAP during low water outside. Twice a day four meters of decline, unlike IJmuiden, where the daily decline is a maximum of 1.4 meters. The other cause is due to the fact that at IJmuiden, filling is mostly done with salt water, while at Terneuzen, filling is more often done with sweeter water from the canal, resulting in higher forces. As a result of the tests, it was decided not to fill and empty through the door. So there had to be another, more complex solution with sewers next to the gully," Kortlever said.

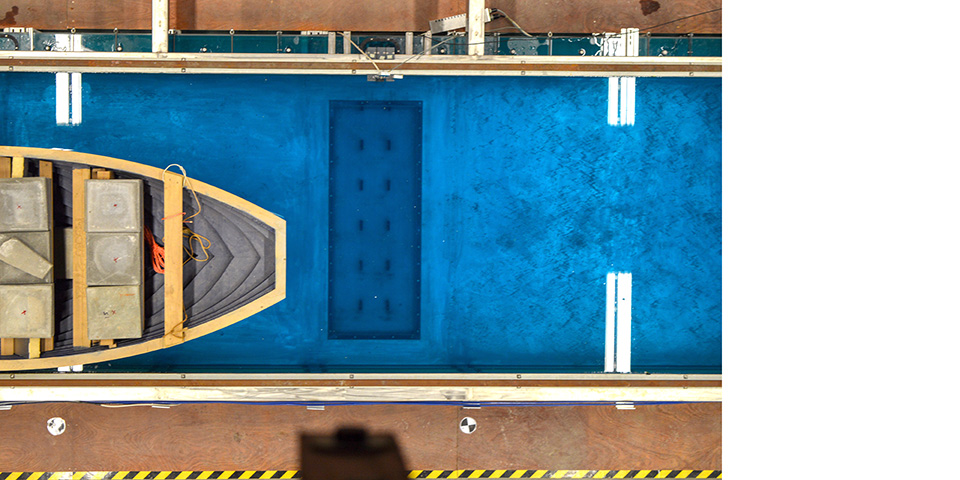

The New Lock will be emptied and filled on the model of the Western Lock.

Short circulation sewers also failed the test

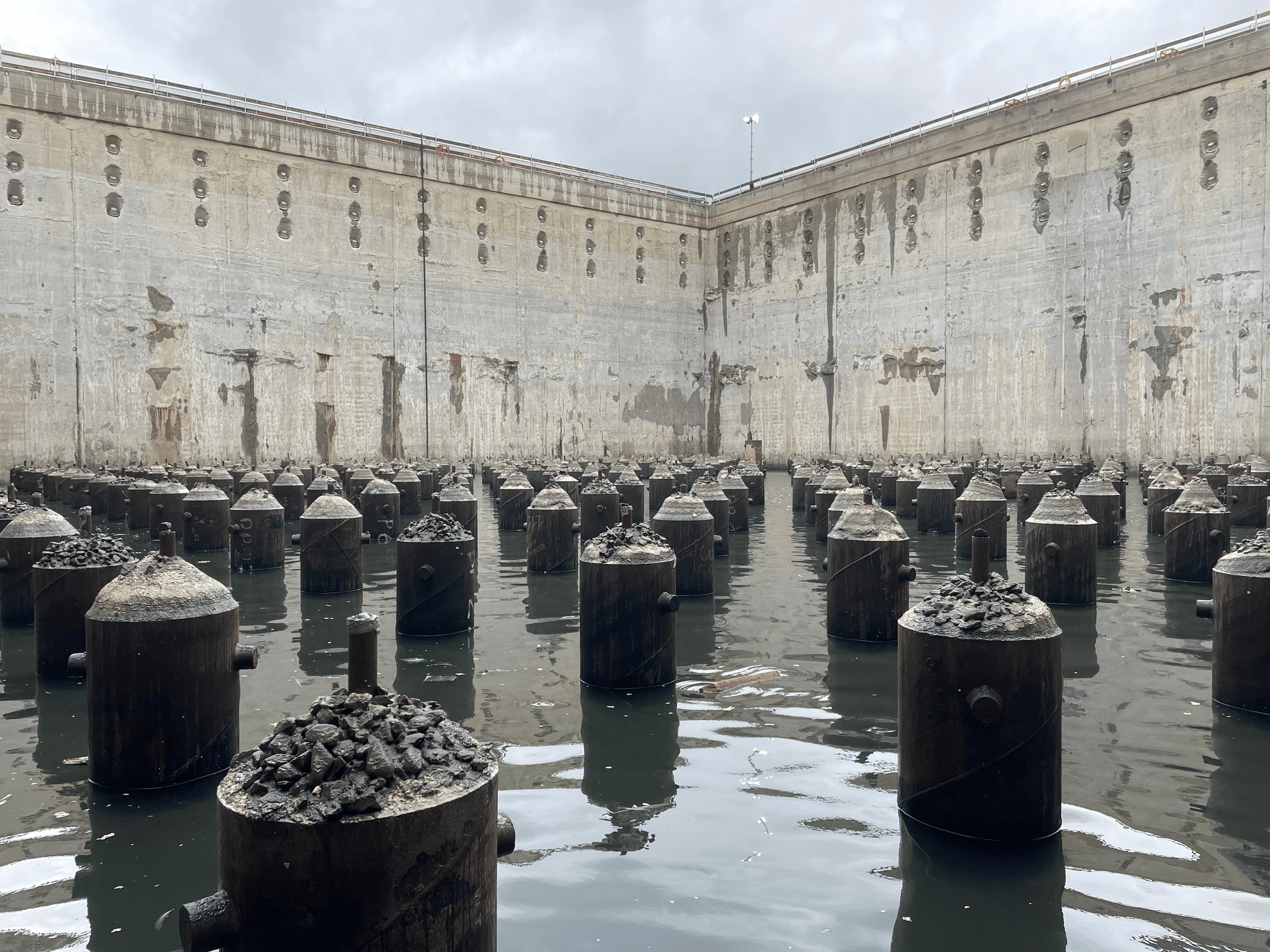

"Another option was to see if for the New Terneuzen Lock we could suffice with circulation sewers, only around the doors and with fill openings in the column wall close to the door. However, the scale model tests at Deltares showed that even with this system the water forces on the ship would be too high, causing the ship's mooring lines to break. The scale model in Delft is ideally suited to simulate the combined process of filling the chute, with the transition from salt to fresh water, and to measure the resulting forces on the moored ship. Computer simulations are not yet capable of including all relevant physical processes at once," Kortlever outlines. "The final solution was found by looking closely at the Western Lock in Terneuzen. That fills kolk at about 1/4th and 3/4th of the longitudinal axis, from gratings in the kolk bottom. Water is fed to the grates through a large sewer that runs along the entire west side of the colk. By filling not from one side at the doors but from two points in the flume bottom, you distribute the water flow more evenly and there are fewer forces on the vessel. Therein lies the chosen solution: the New Lock will be emptied and filled on the model of the Western Lock. We then adjusted the contract requirements for construction accordingly."

New computer simulations as blueprint for actual scale model

Key dimensions of the fill and empty system were then determined based on comparisons with other locks. "A few system features are called for in the contract," Kortlever continued. "How fast you can bring the water into the gully depends on the capacity. The capacity is therefore also requested in the contract, as well as an even distribution of the water supply through the filling points. As with the design of the IJmuiden door-filling system, computer simulations and calculations demonstrating compliance with all contract requirements were requested at the tender stage. The contractor was required to provide new proof after tendering by means of new computer simulations. The fill and empty system tested in the current scale model is based on the contractor's final computer simulations. "

The scale model in Delft is ideally suited to simulate the combined process of filling the flume, with the transition from salt to fresh water, and to measure the resulting forces on the moored vessel.

And then the time came...

The contract was awarded to contractor combination Sassevaart in the summer of 2017. Somewhat in advance of this award, preparations for the actual scale model began. "In Delft we arranged the creation of the exact scale model of the New Lock Terneuzen. We supervised those preparations and extensively tested the elaboration of the scale model. We were finally ready in September 2017 to convert the scale model from IJmuiden to Terneuzen. Deltares accurately recreated the design of the filling and emptying system, which Sassevaart adapted based on the final computer simulations, in the scale model. We started testing in the summer of 2018, after the scale model was delivered in July of this year. It is always an exciting and joyous moment when water is put into the model for the first time. After the summer, Deltares completed the tests and we determined the final system properties, after which they could be passed on to Sassevaart."

Finding solutions within the geometry

"The testing continues. Should any surprises emerge from these, we look for solutions within the geometry of the design. Again, what happens at Deltares cannot be simulated in a computer model. Remember that the New Lock is located at the transition from fresh to salt water. Then you are dealing with a difference in density and thus with so-called density currents. Simulating the density currents during the filling of the chute is also not easy with a computer model. Density currents produce a different force on a ship than when only fresh or only salt water is involved. Only the scale model can reveal what happens then. Deltares has both fresh and salt water tanks and we therefore fill the stainless steel tank with both, depending on which door is open at the time. The whole testing procedure is an extremely dynamic process," Kortlever concludes.