How ultra-high strength concrete can solve structural problems

The material fiber-reinforced ultra-high strength concrete (vvUHSB) is already being used on a regular basis. Well-known examples are very slender balconies, aesthetic elements and stairs in forms that are impossible or difficult to realize in traditional concrete types. The application of vvUHSB in civil engineering structures is still in its infancy, although some very slender bridges in vvUHSB have now been realized in the Netherlands with a minimal amount of construction material.

Several (graduate) studies on the material properties and behavior of vvUHSB have been conducted in recent years. These clearly show that vvUHSB performs better than traditional concrete types. The application possibilities in civil engineering structures are promising. Iv-Infra is investigating in which (parts of) civil engineering structures this high performance of vvUHSB is of added value.

What is vvUHSB?

Fiber-reinforced ultra-high strength concrete is an extremely strong and durable type of concrete in which (part of) the mild steel reinforcement is replaced by steel fibers. At first glance, the material appears to be very similar to traditional types of concrete. However, there are significant differences in the compressive strength, tensile strength and ductility of the material. These differences have a major impact on the performance of the material and are explained in more detail.

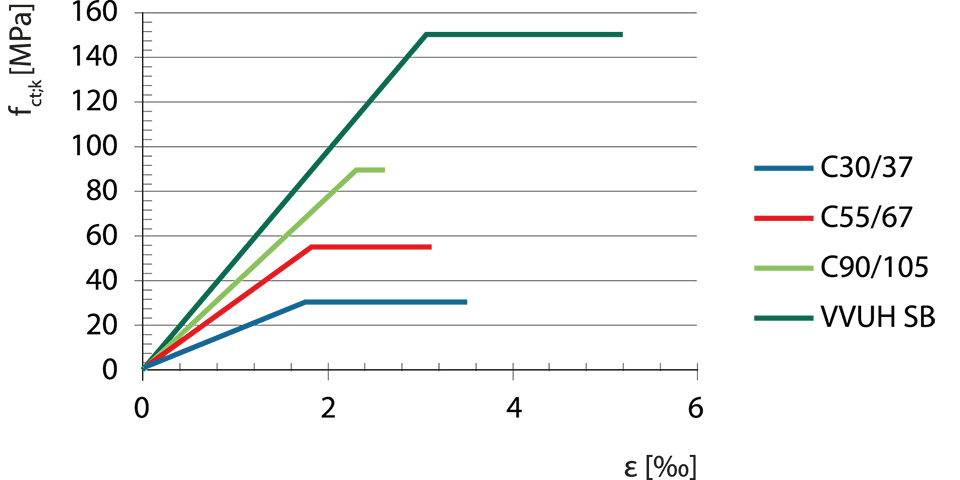

The minimum (cylinder) compressive strength of vvUHSB should be 150 MPa where many applied traditional concrete types have a compressive strength of 30 to 50 MPa. To achieve this high compressive strength, the composition of vvUHSB consists of a balanced mixture of cement, water, aggregates, fillers and admixtures. This composition results in a refined and compact granular skeleton in which virtually all hollow spaces are filled. Due to the filling of these hollow spaces, in contrast to traditional concrete, the force transfer in vvUHSB takes place via both the aggregates and the cement stone. In addition to optimized force transfer, the compact granular skeleton ensures low permeability and thus a high resistance to penetration of water and other harmful substances, even with concrete coverings of only 10 to 25 mm (depending on the environmental class in which the construction is located).

Figure 1: Stress-strain diagram of cylinder compressive strength.

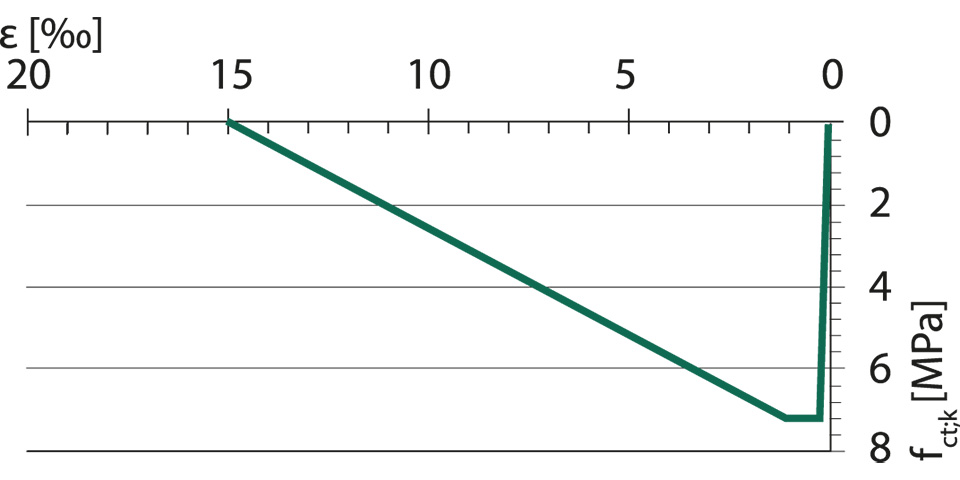

Soft steel reinforcement is activated once the concrete cross-section is cracked. In vvUHSB, small fibers are used to increase the tensile strength of the concrete cross-section in the uncracked state. Due to their size, the small fibers (10 to 20 mm) reach tension relatively quickly and bridge the micro-crack formation from which the higher tensile strength is derived. In vvUHSB, the tensile strength varies between 7 and 15 MPa where traditional concrete only achieves tensile strengths between 1.5 and 3.0 MPa.

Figure 2: Stress-strain diagram bending tensile strength.

Bridging micro-crack formation delays the onset of the first macro-crack. When the tensile strength is exceeded, the micro-cracks grow into macro-cracks. From the onset of the first macro crack, we talk about cracked concrete. This cracking always occurs at the weakest location of the material. In traditional concrete, this is through the cement stone. With vvUHSB, on the contrary, the cement stone is the strongest component in the granular skeleton and the crack occurs through the aggregate.

In order to provide the material with sufficient formability and to further increase the tensile strength, long fibers (30 to 60 mm) are used which are activated after the occurrence of the first macro-crack. Where traditional concrete exhibits brittle behavior and fails without warning when unreinforced or with too little reinforcement, vvUHSB undergoes a certain deformation prior to failure by adding these long fibers and thus issues a warning.

Another important property of the long fibers is the fine distribution of macro-cracking. This is because the fibers are present "everywhere" in the cross section where mild steel reinforcement is only locally effective is because of the mesh between two reinforcing bars.

How do you design with this material?

Since the effective date of the 2012 Building Code, the Eurocode is the prevailing standard in Europe for constructively safe and sound design. Per country these standards contain additional requirements, parameters, explanations and recommendations which are laid down in national annexes. In the Netherlands, civil concrete structures must meet the requirements in accordance with Eurocode 2.

Constructions in vvUHSB are to date (partially) outside the scope of Eurocode 2 because this standard applies to concrete strength classes up to C90/105 and does not prescribe regulations regarding reinforcement with steel fibers. Currently, Model Code 2020 is in process. This will include proposals regarding construction with vvUHSB. It is expected that these proposals, after verification, will be included in a new version of the Eurocode (or added to Eurocode 2). Until this new Eurocode exists, the most practical way to design with vvUHSB is through Eurocode 2, combined with recommendations/guidelines in case of deviations.

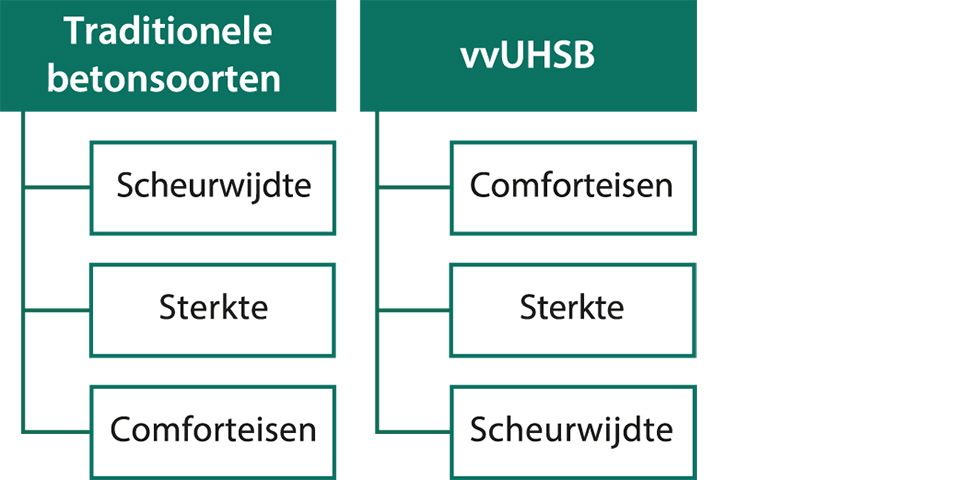

In addition to a difference with regard to standards and regulations, vvUHSB requires a different design process. Based on a case and parameter study by Iv-Infra, it appears that different design criteria are normative for civil engineering structures made of vvUHSB compared to traditional concrete types. With traditional concrete, the crack width is usually normative because of the crack width requirement of 0.2 mm associated with an environmental class in which de-icing salts are present.

At vvUHSB it turns out that in the case study, the failure moment is actually normative with respect to the crack width requirement. This is the result of the fibers' ability to bridge micro-cracks and distribute the macro-crack pattern more finely over the concrete surface.

However, compared to traditional concrete, more attention must be paid to the comfort requirements regarding vibrations and deflections. For massive traditional concrete cross-sections, these requirements rarely pose a problem in practice. In vvUHSB structures, on the contrary, this criterion turns out to be one of the most decisive factors within the design.

Figure 3: Relevance of design criteria.

Where does the material offer opportunities?

Despite the fact that vvUHSB has increased performance with respect to almost all material properties compared to traditional concrete, traditional concrete will not be completely replaced by vvUHSB. One of the main reasons for this is the cost. Besides the fibers required (often about 2.5 % by volume) and the high cement content, the other additives to achieve a balanced mixture are costly. In addition to the mixture composition, much attention should be paid to the design, mixing, processing, transportation and execution.

The application of structural overlay is a civil engineering application option that showcases the high performance of the material. Structural overlay is a common measure in existing structures to increase the load-bearing capacity. Because of the high performance of the material combined with the lower required concrete cover, a relatively thin vvUHSB overlay can achieve a significant capacity increase. A thin overlay reduces the increasing resting load on the current foundation. In addition, a vvUHSB overlay is a durable and wear-resistant solution. Because of the compact granular skeleton, there is virtually no penetration of de-icing salts and chlorides. Also, the overlay does not require an asphalt or wear layer. All this results in a durable solution with little to no future maintenance.