Helicopter view prevents surprises

In a prestige project, such as the renovation and renewal of the wastewater pressure pipeline (AWP 2.0) in West Brabant, it is important not to lose sight of the scope under any circumstances. Within the PAUW combination, Royal HaskoningDHV acts, among other things, as BIM coordinator for all parties and oversees the big picture. To avoid surprises, the consultancy and engineering firm uses a Virtual Commissioning model or digital simulation to test the arrangements of the pumping stations. Unique by Dutch standards.

Digitization

GMB Water Quality & Installations has relied on the consultancy and engineering firm's expertise for many years, according to Maartje Wise, Project Director at Royal HaskoningDHV. "We have been working together company-wide for many years in various areas, ranging from dike reinforcement, pumping stations, et cetera. That collaboration seems to be steadily intensifying. For project AWP 2.0, we went through the tender together with the other PAUW partners. The fact that only two other providers were involved indicates the complexity of the project. The risks are high and that is why on this project we focused heavily on digitization and clash control. Incidentally, it is ingrained in our strategy to make big strides in digital transformation company-wide."

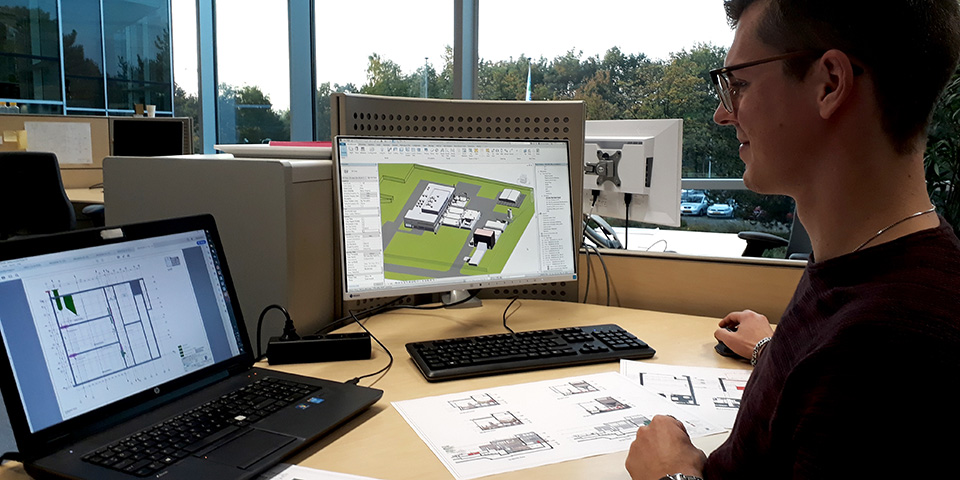

Royal HaskoningDHV is coordinating the entire 3D drawing work for AWP 2.0.

Puzzle pieces

At AWP 2.0, Royal HaskoningDHV is responsible for hydraulic design, civil-construction design, mechanical engineering coordination, peripheral coordination of control plans for the pumps and BIM coordination for all PAUW partners. "The cooperation between all partners runs like a well-oiled machine," says Maartje. "The communication is open and transparent, really everything is negotiable. It's also nice to overcome potential risks. At Royal HaskoningDHV, we now work with BIM in almost all infrastructure projects. We have a lot of knowledge of 3D modeling and for AWP 2.0 we coordinate the entire 3D drawing work, so that all the pieces of the puzzle fit together nicely in one integrated model. This also provides the opportunity to perform clash checks so that any issues surface early. What is truly innovative is that we are creating a Virtual Commissioning design of the AWP, a virtual model that can fully simulate the process between the Factory Acceptance Test (FAT) and the Site Acceptance Test (SAT)."

Virtual Commisioning

Christiaan Nieuwenhuizen, Hydraulic Engineer at Royal HaskoningDHV, explains the Virtual Commisioning (VC) model. "It is in fact a digital test environment (digital twin) of Pentair Nijhuis' pumping systems and the long discharge lines, which we can use to test the pump control, as designed by Hoppenbrouwers Techniek. We can then virtually see how the pumps and conveyor system respond to different situations. In fact, it is often not possible to test all scenarios in reality due to lack of sufficient water. All possible variations or deviations that could occur are considered using the VC model. This is to avoid surprises later in practice." Maartje adds: "The VC model fits completely into our digital transformation. Especially on such a complex project as this, it is an enormous added value if you can eliminate or reduce risks."