Hard work is being done on the "new Leids Ontzet"

Anyone familiar with patriotic history knows that Leiden suffered under Spanish occupation during the 80 Years' War. The Siege of Leiden began in 1573 and ended on

Oct. 3, 1574, thanks to the battling Sea Beggars.

We make a jump to today, 2020. Leiden is once again plagued, this time by a clogged traffic artery. The current N206 that runs straight through Leiden is jammed every day. The road forms the link between Katwijk and the A4.

The TBM digging wheel used to scrape the soil loose from the digging face. (Image: Rick Keus)

The weapon in the fight against traffic chaos is called "RijnlandRoute." The contemporary Water Beggars going to war are the people working for the COMOL5 consortium (for a detailed account of this project see box).We speak with three of them, Arjan van der Put, project manager bored tunnel at Province of South Holland (the client), Joost Vervoort, lead engineer bored tunnel at COMOL5 and Thomas Schubert, project manager bored tunnel at COMOL5 (An international contractor combination of the TBI companies Mobilis and Croonwolter&dros, VINCI Construction Grands Projets and DEME Infra Marine Contractors). The theme: tackling the A4, A44 and the construction of a new road (the N434) including the drilling of two tunnel tubes.

RhinelandRoute plan has been around longer than many think

"Did you know that a similar plan to the RijnlandRoute dates back to the 1940s?" opens Van der Put's conversation. "The RijnlandRoute was already being talked about back then. For decades, this plan came up regularly. Now it's finally here and everything is actually coming to fruition. It is necessary. If we look at the tunnel route of the RijnlandRoute, we see that there is relatively little urban development. This is because the construction of the RijnlandRoute has been taken into account since the 1940s. People in the Stevenshof area have already been informed when they moved in that there would one day be a road."

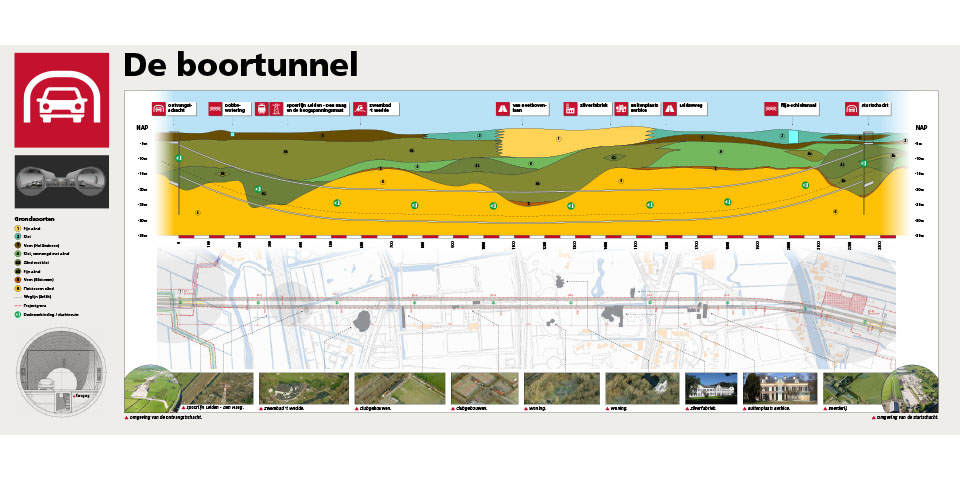

The construction of the N434 consists of a 2.5 km tunnel. At the time of this writing, the first tunnel tube has been completed and preparations are underway for the drilling of the second tunnel tube. "There is drilling under houses, under high-voltage pylons, under sports fields," Van der Put explains. "If you were to build a road above ground level, it would create an enormous barrier. A tunnel with sunken bins at the connections is ecologically and infratechnically the best solution. An elegant solution, which is also optically acceptable to local residents."

Tunnel vision, but in the good sense of the word

Van der Put can credit himself with true "tunnel vision," but in a positive sense. "Province of South Holland hired me for this project because of my expertise. At Rijkswaterstaat, I was involved in the first tunnel drilling project in the Netherlands at the time, and later I did more drilling projects at other companies. For the RijnlandRoute, I came to the table as early as the dialogue phase, when the plan of requirements was being drawn up."

The National Tunnel Standard was drawn up for rectangular tunnels. The fact that the RijnlandRoute will feature a circular tunnel requires expertise to make the necessary translation. "We were very successful in this," Van der Put explains. "For example, we designed the cross-connections between the tunnel tubes larger. These are used as escape routes. After all, a tunnel must first be empty before people can flee to the safe tunnel tube. Because of the larger cross-connections, more people can be in there, so the evacuation process can proceed safely."

A mound for back pressure

A mound for back pressure

The first criterion for being able to start drilling the tunnel is that there is enough soil above the drill bit, at the location where it will be started. "That must be about the same height as the diameter of the drill bit. That's why we created a drilling mound at the place where drilling started, of 3.5 meters high. Looking at the course of the tunnel, the ramp starts at ground level and eventually drops 30 meters at its deepest point. The starting shaft is 20 meters deep," Van der Put explains.

Thomas Schubert, drilling tunnel project manager at COMOL5: "At the site where the tunnel is being realized, we find a special geology. Lots of water, especially at the beginning and at the end of the tunnel, sand, loam and an organic soil. The whole is very sensitive and transmits any kind of movement. Despite the fact that I have been involved in several tunnels, including in The Hague, this tunnel near Leiden is a special case. That is why we really had to find the right balance between cost and what is technically possible." The total duration of making a tunnel tube is planned at about 175 days. "It took a little longer with the first tunnel tube," Schubert continued. "The drill traveled about 15 meters per day. The drilling process is a repetition of two main phases. The first phase consists of drilling with the addition of a bentonite suspension. The bentonite keeps the digging front in the digging chamber stable. The TBM digging wheel scrapes the soil loose from the digging face. The soil and bentonite mixture is discharged to a separation unit located at ground level. The bentonite is reused. Phase two consists of placing the tunnel rings, precast concrete elements that make up a concrete ring. These are placed behind the drill. This whole cycle is interrupted only to keep extending all the pipes and cables."

The Tunnel Drill is impressive to say the least. (Image: Rick Keus)

Good preparation is half the battle

Joost Vervoort, lead engineer bored tunnel at COMOL5, specializes in underground construction. He came into the picture during the tender in 2016 and started on the project after the contract was awarded in January 2017. "The call for tenders asked us to do the design and engineering of the bored tunnel, such as the lining, the cross connections and also the layout of the tunnel including cable ducts. The temporary structures were also addressed, such as, for example, the drop-off frame needed for depositing the drilling machine at the start of drilling. I then made pressure calculations for the deposition forces," Vervoort explains.

The environmental impact of drilling the tunnel was also considered. Vervoort: "Think of the settlement of the ground level and the influence on buildings in the area, for example. Everything that could be calculated in advance was calculated. During the drilling operations, we mainly check the drilling front stability and the process itself. A tunnel that you make this way simply has to be right the first time; you can't 'just pull the drill back'. At ground level we take measurements, but also in the tunnel and the TBM itself. Before the Rhine-Schi canal would be passed, a test field is set up, we monitor that. An extra precaution for the critical passage of this canal."

Every tunnel is unique. The tension is to design the tunnel so that it not only meets the client's requirements, but that the tunnel is also practical and efficient to construct. "Ultimately, the same applies to the tunnel: the more reinforcement you apply, the more expensive everything becomes. We found a good balance in that," Vervoort explains. Until when will he remain in the picture on this project? Vervoort answers, concluding, "Until the phase in which the cross-connections are realized. Then the structural work is largely finished."

RijnlandRoute

The RijnlandRoute is a new road link between Katwijk, via the A44, and the A4 near Leiden. The road solves current bottlenecks and guarantees traffic flow in the Holland Rhineland region, especially around Leiden and Katwijk.

Two of the three RijnlandRoute projects are now under construction. The N434/A44/A4 project, which includes the bored tunnel, is being carried out by contractor combination COMOL5, the N206 ir.G. Tjalmaweg project by Boskalis. The third project of the RijnlandRoute, the N206 Europaweg, is still in preparation.