"Made in Holland" geogrids with Enka Solutions

As a leading and globally active producer of engineering geosynthetics, Low & Bonar, with Enka Solutions, offers a wide range of products that contribute to optimal design within construction and civil engineering projects. Naturally, geogrids are part of this.

"Geogrids have been used for decades in reinforced soil structures and various types of pavements and continue to enjoy growing acceptance due to proven technical performance and savings in construction time, carbon footprint and extension of the design life of projects, among others. Enka Solutions therefore offers under the brand name EnkaGrid® a wide range of high-quality geogrids, produced at our Arnhem location and applied worldwide," said Van Malenstein, Sales Manager Enka Solutions.

EnkaGrid MAX

EnkaGrid MAX is a rigid biaxial geogrid, for pavement structures ranging from unpaved roads to heavy-duty crane sidings and railroads. EnkaGrid MAX is available in different strengths, so there is a suitable product for every project.

Mechanisms determining the performance of geogrids are complex, but load spreading and lateral confinement of the granule are the most important. Both are related to the interaction between geogrid and aggregate. The strain of a geogrid during service life generally does not exceed 2.0%. Therefore, at low stress levels, the product should already have sufficient tensile strength to absorb loads. Nowadays, however, the term stabilization is also increasingly accepted for geogrids used at low strain levels (Giroud Han 2016). Based on this definition, radial secant stiffness in kN/m is a more important parameter than tensile strength. For biaxial geogrids, it can be tested in accordance with EN ISO 10319. A modified test method (ETA 12/0530) has been developed for differently shaped hexagonal geogrids.

When developing EnkaGrid, the goal was obviously to achieve maximum performance. Because EnkaGrid MAX consists of pre-stressed strips, high values are achieved on said parameters. Thus, the EnkaGrid MAX 30 achieves a tensile strength of 12 kN/m at 2% strain, the nominal tensile strength is already achieved at < 7% strain, and the radial secant stiffness is as high as 725 kN/m at 0.5% strain.

New 3-in-1 solution

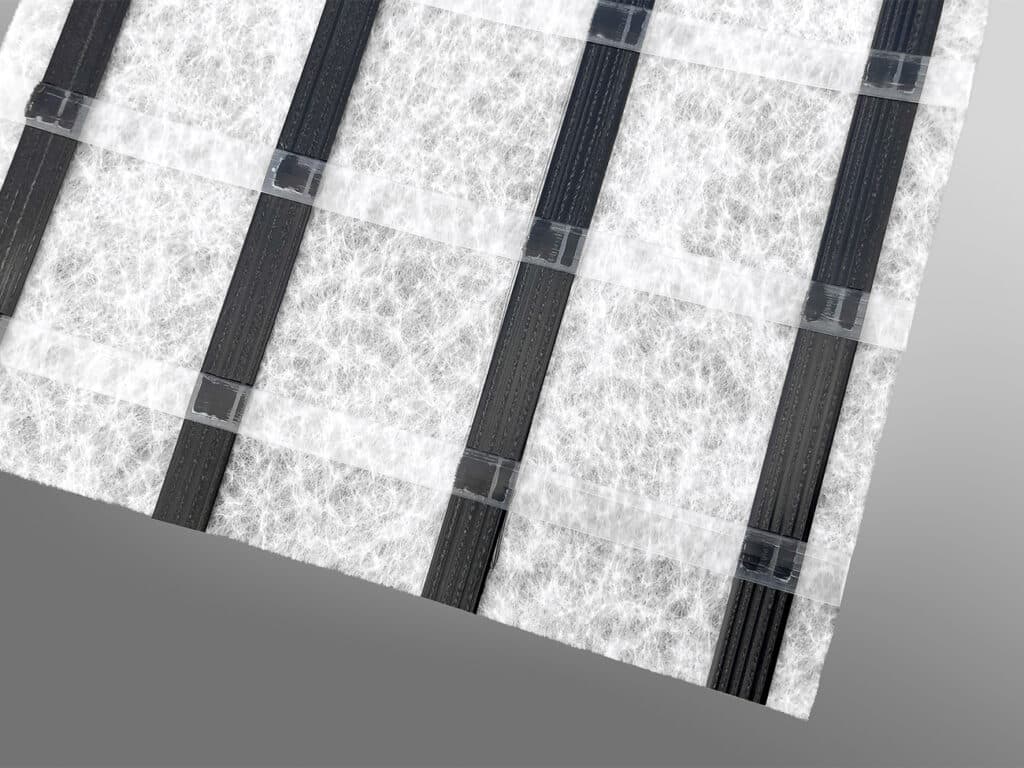

"To ensure proper separation and filtration, biaxial geogrids are often combined with an underlying separately installed geotextile. For customers, however, this means extra work in procurement, planning and execution. This is why we are introducing EnkaGrid MAX C. A 3-in-1 solution," said Van Malenstein. "By combining EnkaGrid MAX already ex-factory with a non-woven geotextile, we can respond even better to the needs of our customers. Common variants will be available from stock, but our production method allows us to respond customer-specifically to specific project needs."

EnkaGrid PRO

Van Malenstein: "EnkaGrid PRO is our uniaxial geogrid. It too is produced from prestressed strips. We apply EnkaGrid PRO mainly in reinforced soil structures, such as noise barriers and steep wall constructions. Depending on the integration into the surrounding landscape, combinations with precast concrete elements or steel mesh can be made. But a combination with our EnkaMat is also possible, if one wants to build a green embankment construction. EnkaGrid PRO has a BBA certification and on this basis so-called 'Long Term Design Strengths' can be determined, which the designer can use in his or her design calculations."

Technical Support

"From our expertise, we stand for quality products. But we are not just about supplying products," says Van Malenstein. "Our added value lies precisely also in the support of our technical specialists during the design phase. With this, we contribute to optimization, where our knowledge and experience make the difference."