From conversion to self-assembly of machines

"When the ideal machine does not yet exist, we develop it ourselves," says Marc Timmerman, owner of Van den Heuvel (VDH).

"Our added value really lies in converting the customer demand into a machine design so that it is suitable for those customer-specific purposes. To respond even better to the specific issues from the market, VDH is focusing more and more on building machines themselves, in addition to rebuilding them." Timmerman explains that the VDH-MP60 was initially developed based on a specific customer request, but is now the basis for the complete MultiPurpose series that VDH is building.

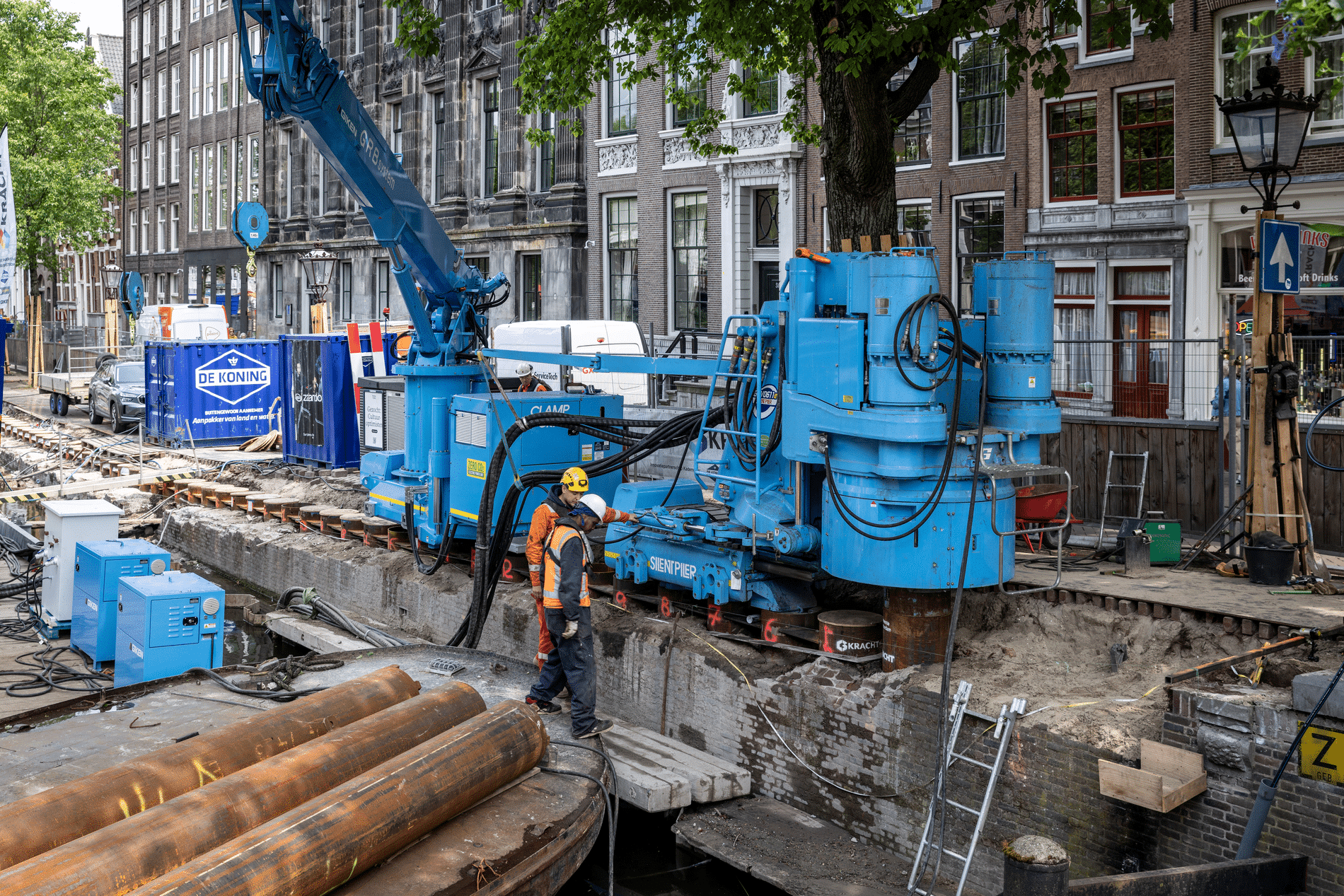

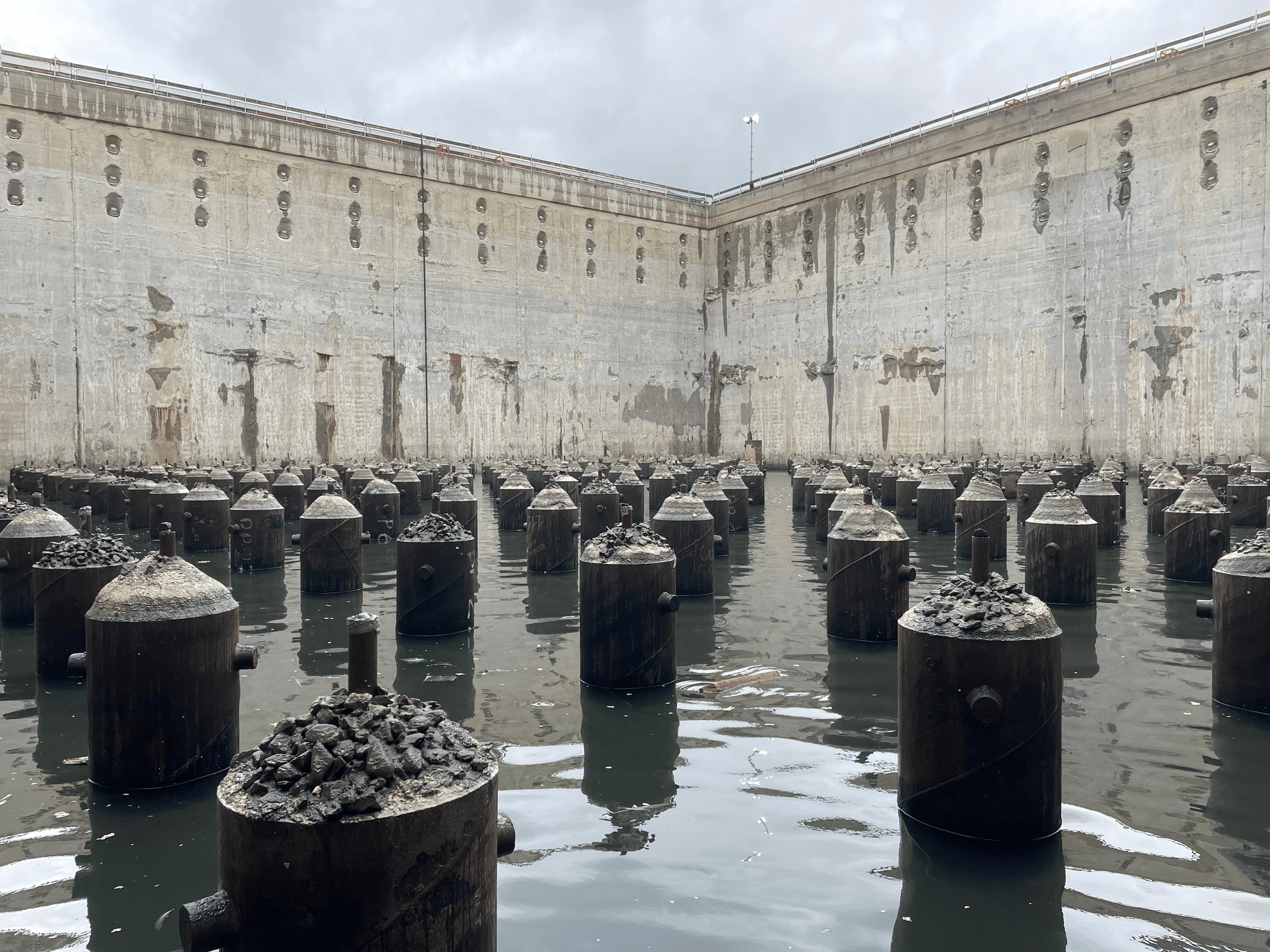

MultiPurpose Series

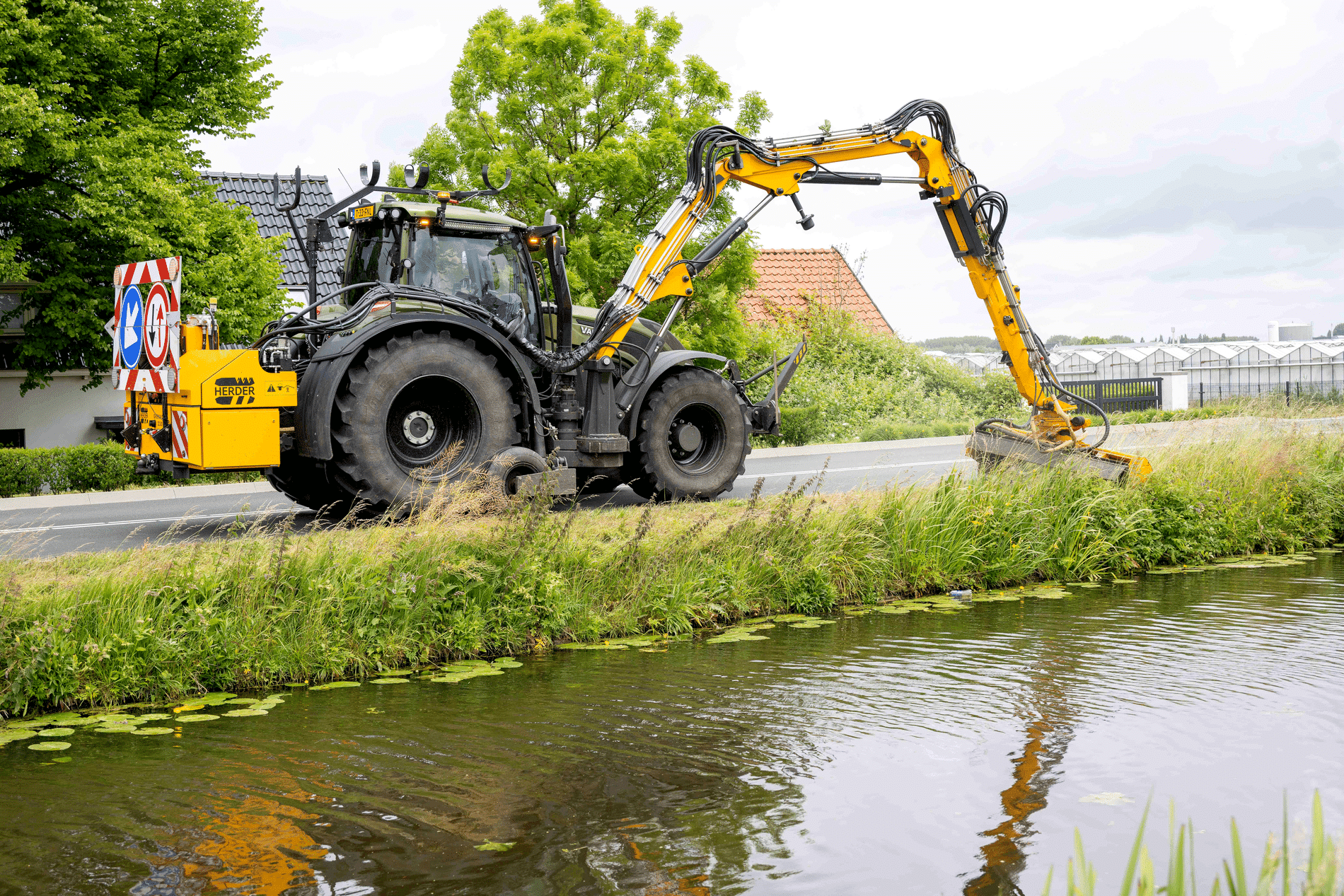

"The MP series includes machines that can be widely used in varying foundation work. For example, the MP60 can be used for pile driving as well as displacement drilling, mortar screw pile drilling and vibrating mini-vibro piles. The MP40 is -depending on what you hang in front of it, suitable as both screw machine and pile driver. The machine can be transported including the drill box and drill bit, making it extremely suitable if you work on several smaller projects per day. The MP70 is equipped with a broker equipped with rack and pinion system, ideal for inner-city projects or work inside buildings. Thanks to the quick-change system, the equipment can be easily changed: from pressure block to pile driver and drill cabinet."

No concessions

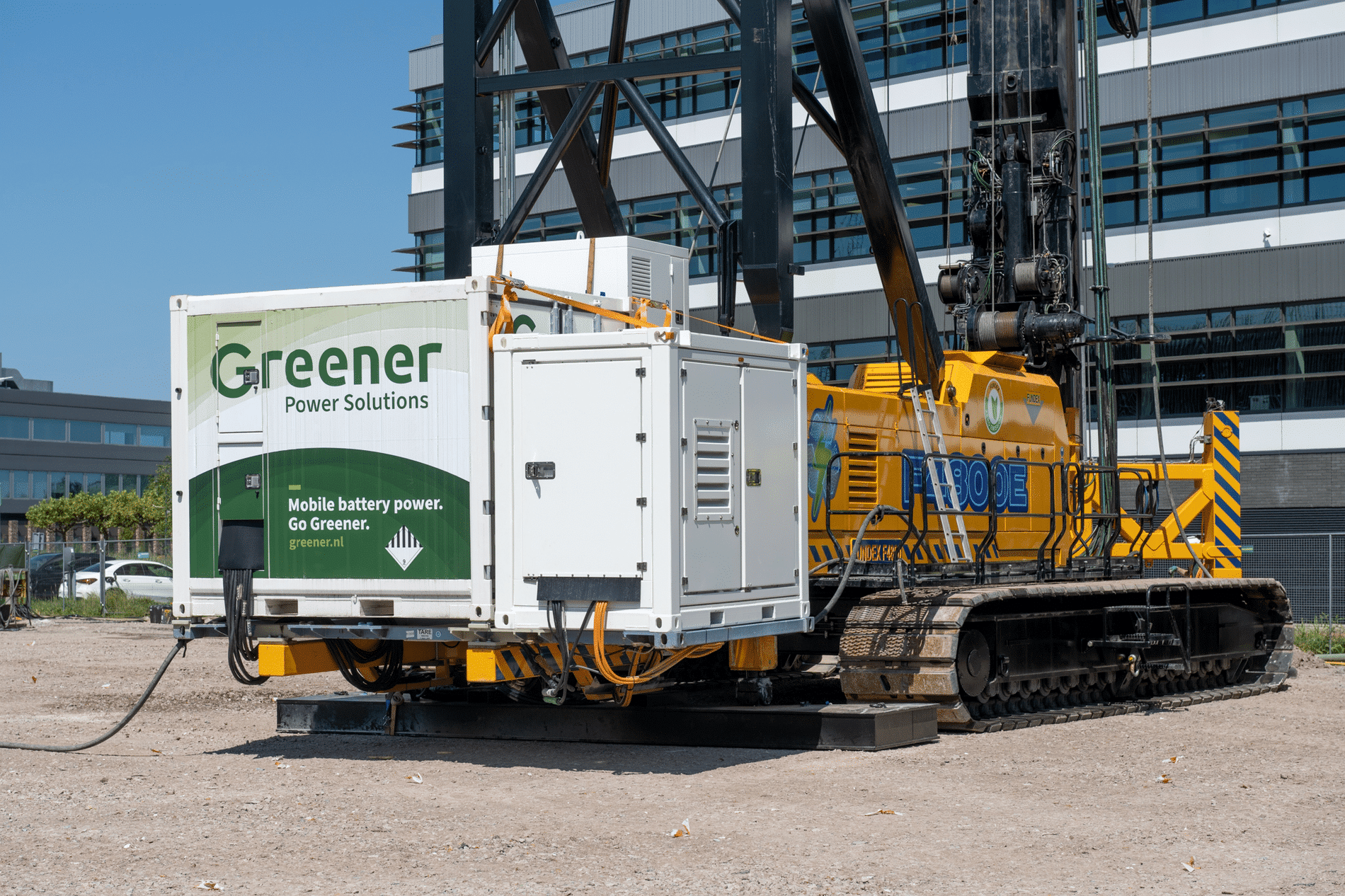

The biggest advantage of building yourself, according to Timmerman, lies in the fact that you start engineering from scratch, in order to match the customer demand as closely as possible. "Without making concessions because you would be working with already existing machines. With a modular machine as a solid base, you're going to fill it in flexibly according to the customer's wishes. In that we are flexible in motor power or the pumps we put in. Of course, our experienced engineers know how to convert the wishes and requirements into a design, 3D drawings are made and capacity and strength calculations are performed. Then everything is built and preserved in our fully equipped metal and hydraulic workshop and paint shop by our skilled people into a high-quality final product."

Solution-oriented foundation techniques

Three VDH-MP60s are already in the market, and the MP40 and MP70 have already been sold and will be delivered soon as well. "Unseen," says Timmerman. "It's great that our customers order machines without us having even developed them. They trust that they are getting a perfect machine for their purpose and operations, which is what we are known for." In addition to the MP series, VDH is also building mini pile drivers, rail track machines and a 65-ton pile driver. "We never stand still," concludes Timmerman.