Sustainable widening of A1 Apeldoorn - Twello motorway

Emission-free, circular and with new technologies

Heijmans and Rijkswaterstaat have a shared ambition to work climate-neutrally on a healthy living environment. With the widening of the A1 motorway between Apeldoorn and Twello, they are making this a reality. The project will be carried out with zero emissions as far as possible, existing materials will be harvested and reused, and there is even room for applying product innovations and new techniques. It is rightly a unique road construction project in the world that is also attracting considerable international interest.

The widening of the A1 between Apeldoorn and Twello is the second phase of the widening between Apeldoorn and the Azelo interchange that started in 2018. The widening of the A1 will improve connections between economically important areas inside and outside the Netherlands. Rijkswaterstaat is working on this with the provinces of Overijssel and Gelderland and the Stedendriehoek region. Construction company Heijmans is carrying out the work. Phase 1 between Twello and Azelo (40 kilometers) has now been completed. Heijmans is currently working on the 15-kilometer stretch between Apeldoorn and Twello. "Although the route of phase 2 is a lot shorter, the contract sum is similar to the previous phase. This is because the work is much more complex with many more engineering structures and slip roads, often in the middle of built-up areas," explained Erik Steenbergen, technical manager at Heijmans.

Climate neutral by 2030

The second phase of A1Oost is especially distinguished from phase 1 by its maximum attention to sustainability. "Even in the previous project we asked for the usual sustainability measures, which resulted in, among other things, the construction of a solar park and the use of bamboo traffic signs, but for phase 2 we are going one step further," says Jasper Middelkamp, technical manager at Rijkswaterstaat. "At Rijkswaterstaat, our ambition is to work climate-neutral and circularly with clean and emission-free equipment by 2030. We achieve this in part by including MKI as an obligation in the award criteria. In the call for tenders for the second phase, the request was that, in addition to the usual sustainability measures, we also focus as much as possible on emission-free execution to get the flywheel moving."

Signboard

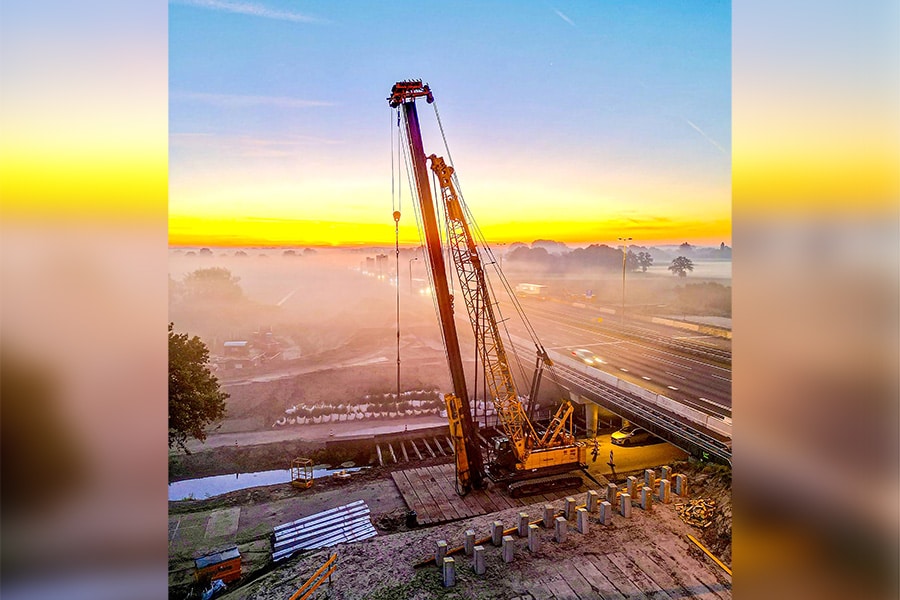

Initially, five candidates had applied for this second phase of the A1 project. After a funnel product, the number of candidates was reduced to three parties. "We then entered into a competitive dialogue and further expanded the theme of sustainability by not only focusing on electric equipment, but also on the reuse of existing materials," Jasper indicates. "That ultimately led to three incredibly nice offers, but Heijmans drew the longest straw." Erik adds: "These are projects that suit us well as an organization, with a lot of civil and asphalt-heavy work with an eye for the surroundings and the environment. We are 'builders of a healthy living environment' and propagate that widely. As a forerunner, Heijmans has freed up extra budget to invest in emission-free equipment, and this project is a showcase for that. The deployment of 48 (!) pieces of electric equipment on one project, including twenty trucks, crawler cranes, telescopic handlers, shovels, drilling trucks, asphalt equipment and a wire crane, is unprecedented."

Second Life

Besides deploying emission-free equipment, Heijmans is taking many other sustainability measures. "We are using innovative techniques and product innovations to achieve a more favorable MKI value. "For example, many materials from the existing acreage are harvested, separated, processed and reused," says Erik. "Think of regular things like the asphalt and concrete, but we also give traffic portals, cables, noise barriers and even the guide rail a second life." Also unique is the in-house production of 32 concrete girders for the expansion of five structures as a sustainable alternative to mass-produced precast concrete girders. "Instead of stripping after one day, we take 28 days for curing. Thus, no additives need to be used and the addition of less cement is sufficient, also in a type with a lower environmental impact. This together provides an MKI reduction of 18%."

Space on the energy grid

The commitment to innovative techniques and product innovations has never hindered the progress of the project to date, according to Jasper. "Surely that is worth a compliment to Heijmans, because on the one hand they are implementing innovations, but on the other hand it is also just business as usual." Doesn't take away from the fact that it is sometimes quite a puzzle to fill a day with the electric machines, Erik acknowledges. "Both the trucks and the cranes have to be recharged in between jobs." Fortunately, on this project, installing the charging facilities was not a problem. "We were there in time," says Jasper. "There was still room in the power grid at this location. However, that is no longer a given, and as a client we are aware of that."

Adjusting speed limits during road works

The A1 between Apeldoorn and Twello is a "busy part of the Netherlands" with a lot of international freight traffic. "A major challenge here is also to keep the road partially open, while the work must be done safely. This is not unique for a road construction project, but does require maximum attention," Jasper believes. "In consultation with the police and the Public Prosecution Service, we at Rijkswaterstaat look at how we can improve the attitude and behavior of road users during road works. Sometimes a campaign to not ignore red crosses helps, but often hard measures such as speed checks are necessary. For example, the Public Prosecutor's Office has deployed a so-called flex flash on this stretch of road, which are regularly moved." Furthermore, Heijmans has narrowed and relocated lanes so that road workers can work safely. To keep it safe for road users as well, a speed limit of 90 km/h has been set on the entire section in accordance with current guidelines.

Lots of outside interest

In early 2023, Heijmans began construction outside. Opening is scheduled for the end of April 2025. "It is currently one of the most sustainable road construction projects in the Netherlands," Jasper expects. "Heijmans manages to halve the MKI compared to the reference MKI with all these sustainability measures. A unique achievement." And that achievement does not go unnoticed. "People are genuinely interested in how we approach it here, how we deal with charging facilities, etc. That makes the project very exciting. We give regular presentations and soon we will even have an international company visiting us. Surely that indicates that we are being innovative," Erik concludes.