Drilling under the track

Traffic on railroads and highways cannot be stopped for the construction of cables and pipes. Yet they must be crossed regularly. Where there is no room above ground, the way underground is often clear. Crossing a railroad line underground does require the necessary expertise to prevent settlement during or after drilling. Van de Beek Gestuurd Boren BV has been a ProRail-certified contractor for more than fifteen years and in that capacity has been engaged by many market parties to design and execute directional and auger drilling under the railroad.

Van de Beek Gestuurd Boren BV has been active in underground infrastructure since 1977 and specializes in the laying of cables and pipelines. "We have the people and resources to lay cable and pipeline routes from A to Z," says Arie jr. van de Beek. "Whether it is an open excavation or using trenchless techniques, we are able to carry this out completely in-house and with our own people. In the open field there are often no obstacles, but in the vicinity of a railroad, for example, additional conditions apply from ProRail. Realizing a directional drilling must then be carried out by a ProRail approved contractor, like us."

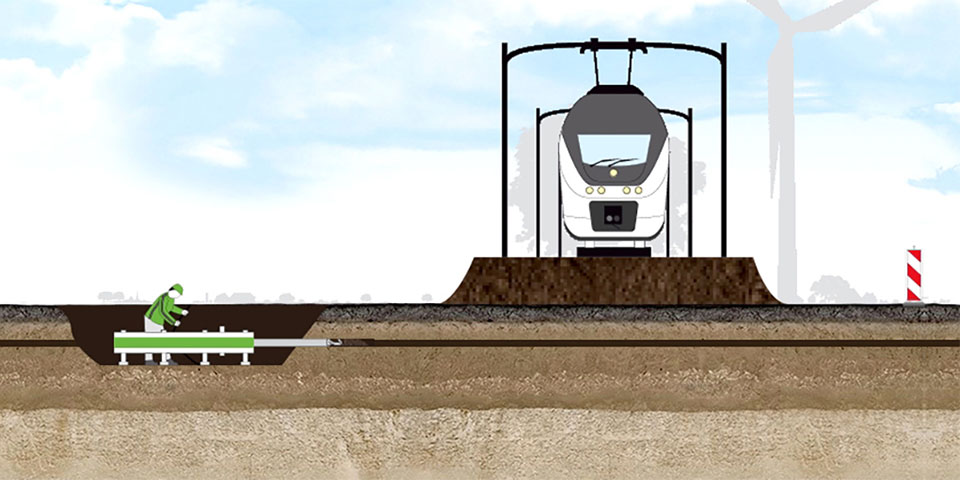

If space is limited, we often choose pilot-driven auger drilling.

Steered versus auger drilling

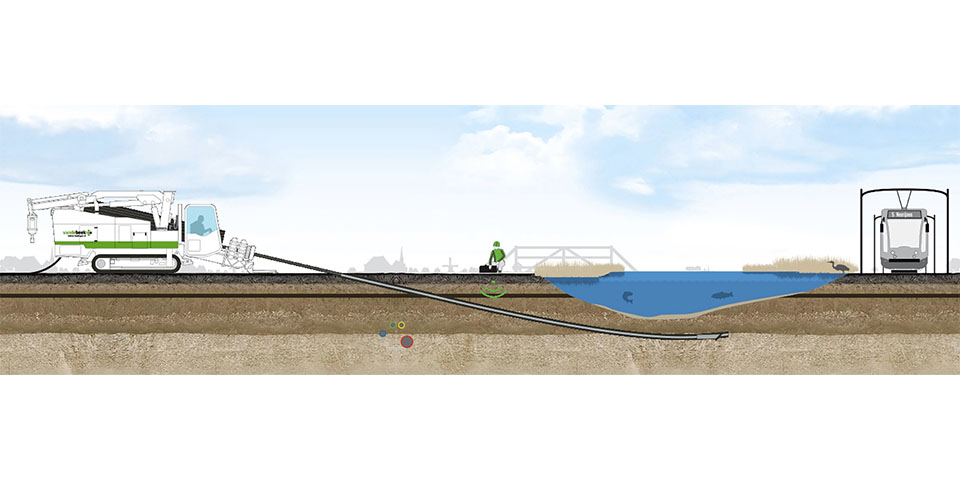

Drilling under the tracks can be done in several ways. "The technique we use depends on the situation and the space available," Arie jr. explains. "What is important in any case is that, for example, a directional drilling remains outside the pressure lines of the track, as laid down by ProRail. We have the expertise and people in-house who will make a thorough design of the drilling in advance based on the requirements set. When implementing a directional drilling, it is important to cross the pressure lines of the track at a safe depth to prevent settlements. With such directional drilling we are able to lay cables or pipelines up to 500 meters trenchless. If space is limited, we often opt for pilot-driven auger drilling. A starting and finishing point is created close to the track. From the starting pit, a pilot rod is first pushed into the ground with great accuracy. The auger (wokkel) and the pipe to be pressed are then connected to the pilot rod. The auger and the pipe to be compacted follow the inserted pilot rod, minimizing deviations from the drilling path. The soil is discharged through the auger via the pipe."

With directional drilling, Van de Beek Gestuurd Boren BV is able to install cables or pipelines up to 500 meters trenchless.

Experience

By means of an advanced gyro-measurement system, Van de Beek Gestuurde Boren BV is also able to record steered drillings or existing pipelines based on the X, Y and Z coordinates. Arie jr.: "Pipeline registration is extremely important, especially under the railroad. Afterwards, we send a gyro-tool through the borehole to determine its exact location. We include this data in the revision drawings that are delivered to ProRail. This technique offers greater accuracy about the location than the standard method." The beauty of ProRail's accreditation scheme, according to Arie jr., is that the experience (years of service) of the drilling masters is also taken into account. "All drill masters who went through the recognition scheme in 2005 are still in office. Experience, in particular, is crucial when drilling under the tracks; the consequential risks are enormous. ProRail sets great store by that. Continuity and experience is also an important factor in the Safety Ladder, for which we are certified at step 3."