A step up from the gutter....

The possibilities of a concealed channel along the track

Concealed Gutters. Extremely suitable for effective drainage of rainwater. But Zwaagstra Beton, a specialist in manufacturing concrete products for various purposes, including concealed gutters, thinks further. The company has not been active in the rail sector for long, but the sector is an excellent complement to the GWW and agricultural sector, where Zwaagstra Beton's range of high-quality concrete products has been used for years.

Zwaagstra Beton has grown considerably and now has four production halls which has greatly increased the production capacity and allows them to continue to serve the increasing demand from the market. In the latest hall (from April 2019) mainly retaining walls, gutters and specials are manufactured.

For a job in Lelystad, the production team at Zwaagstra Beton developed a 'special' that can be used in many more places in the Netherlands, specifically for along the railroad tracks. André Veerkamp, field sales at Zwaagstra Beton, talks about the project and then about the product: "Commissioned by ProRail, VolkerRail is constructing the new Lelystad Opstelterrein. The capacity must be increased because the stabling yard will have to deal with more equipment, a busier timetable and shorter service times. Everything must be kept on track so that the NS can quickly and thoroughly clean, maintain and prepare the many trains for the next day. As many as five tracks wide there are trains in need of cleaning. Not only is it a matter of installing an excellent drainage system along the tracks, but we have also made sure that the cleaners can do their work quickly and efficiently."

The Duo mold made in-house by Zwaagstra Beton in which two gutters can be made at the same time.

Gutter as a guide

When asked how the two things come together, Veerkamp answers, "For effective drainage of water, our concealed gutters are the best choice. Combined with the sand trap, the water is effectively diverted away. Furthermore, the wagon cleaners use an aluminum step cart to access everything. WIe have made the concealed gutters so that this cart runs through the slot of the gutter over the gutter. In this way, we combine a normal line drainage gutter with the guidance of the aluminum step-up facility." Zwaagstra Beton has been making these concealed gutters for years, but normally with a slot of 3.5 cm. "However, the requirement from ProRail is that the trench is 4 cm. wide so we decided to adjust our product standard accordingly."

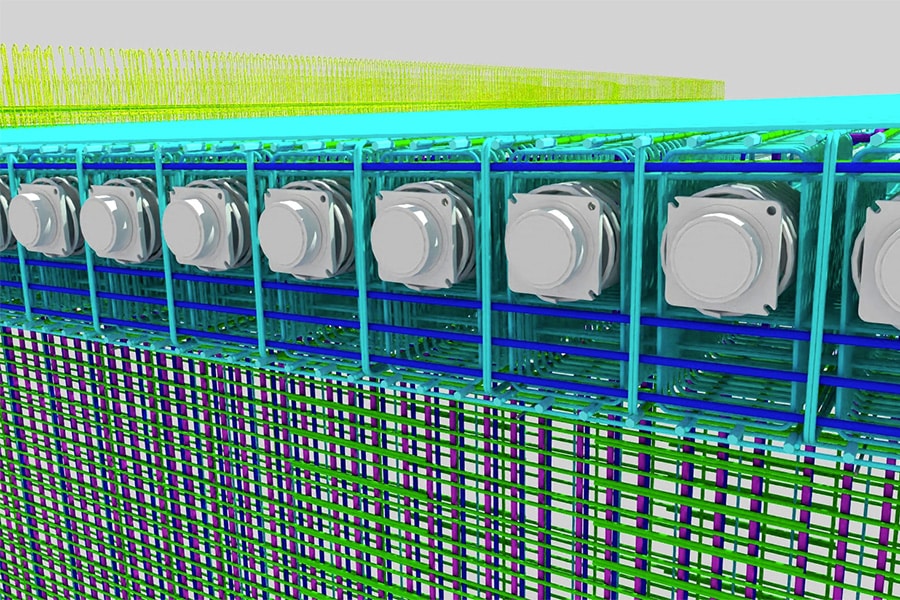

Concealed gutters from Zwaagstra Beton's own factory, made of concrete with tremendously high strength. The gutters are very durable and carry the KOMO quality mark.

Custom molds

"That meant new molds. And éxtra molds in connection with the high demand and fast delivery required for this project. We also made new molds for 1-meter elements, specifically for use along the track so that curves can be made with them. These were also used on this project." Veerkamp says the steel molds are dimensionally stable and super-tight, to ensure a long process of producing in the mold. "And we produced them ourselves. Our mold maker did a very meticulous job and within the specified time."

The concealed gutters made using the Duo mold.

Future-proof

"Thanks to the new molds and the new production halls at Zwaagstra Beton, the production capacity has increased enormously. Also the choice to make a modification to our standard product so that it meets the ProRail requirements and the fact that it has the KOMO quality mark means that we are ready. We have stock, can deliver large quantities quickly, in both long and short pieces. That makes us future-proof towards the railroad world." Besides the (concealed) gutters, Zwaagstra Beton is and remains a specialist in manufacturing concrete products for various purposes. Concrete slabs, retaining walls, but also "specials" such as footings, guide walls of deep-wall tunnels, foundation slabs for solar parks ... and all executed in the best quality concrete. "If it has to be made of concrete, we can make it," concludes Veerkamp.