Rottemer Tunnel: world's first DC-powered energy-neutral highway with tunnel

With 54 different types of technical systems

On October 13 this year, tension was first put on the Rottemer Tunnel. A special moment for construction consortium De Groene Boog, which is building the A16 Rotterdam with Rottemer Tunnel on behalf of the Department of Public Works. Because never before has such a large DC installation been built in the world. In order to test the functional operation of the installations and controls in advance, a digital copy of the tunnel was made, called TWIN-16.

The Green Arch is creator of the world's first energy-neutral highway with tunnel. "A tunnel is of course the big consumer in such a route," says Hans Pos, test manager and creator of the main design, along with Michel van Baar. "Together with the Department of Public Works, we therefore re-examined the concept on which tunnels are built in our country and asked ourselves 'is it still correct with the latest technology?' Pretty soon we came to the conclusion that things could be done better, starting with the power supply. Here we chose to power both the road and the tunnel with direct current (DC). After all, most of the electrical systems run on DC voltage."

From AC to DC

Alternating current (AC) is mainly used for motors (running machines). "AC as a power supply was chosen in the past because we could make higher voltages with it (transformers). With current technology, you can also make higher voltages on DC for transporting energy," says Hans. And as more generation comes from solar and wind (DC installations), the use of AC voltage is less and less obvious. "In the development of residential installations, you see the same thing happening. The house of the future will have a DC network, so you no longer need to charge your phone or laptop with an adapter. That makes DC voltage cheaper and simpler in many systems. LED lighting is also a good example of this and initially runs on DC voltage. And lighting is the biggest consumer in a tunnel. This is why we decided to do things differently for the A16 Rotterdam, partly because the latest technology also allows us to build a reliable and safe DC installation. A DC power supply not only saves on cable thickness, but also reduces energy losses."

350 Volt-DC

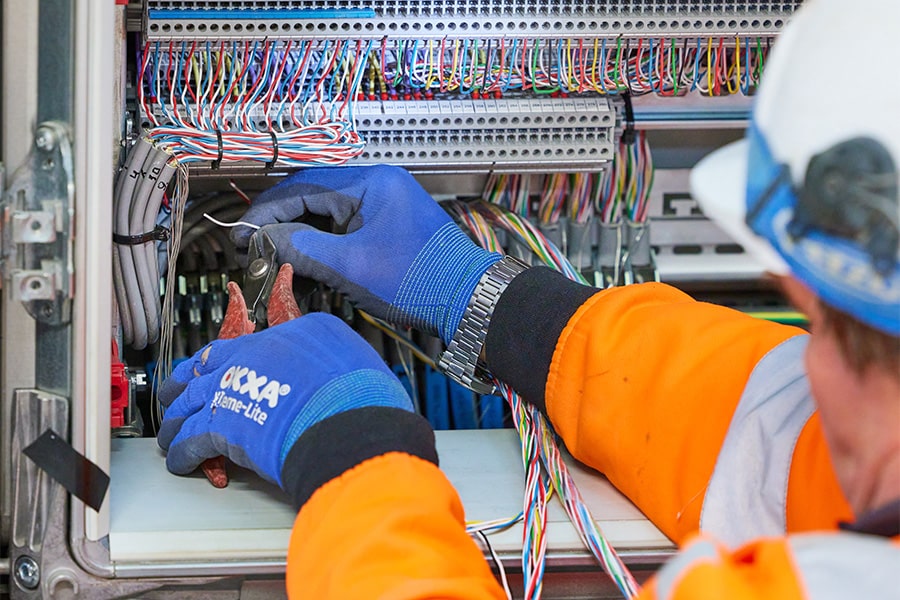

Of course, De Groene Boog did not take such a drastic decision overnight. "We did a lot of research into direct current," says Peter Ottervanger, project manager of procurement and contract management for tunnel-technical installations at De Groene Boog. "And also looked for companies and suppliers in the market with demonstrable expertise in this field. Although the lighting is all LED, the DC installation in the tunnel is laid out at 350 Volt-DC. Existing components, such as the driver of the LED lighting, for example, had to be adapted to this. In the end, we chose a supplier with such a driver in its standard range that was adapted for our DC application. And so, for all systems, we looked for the best solution for this project."

Ideal installation/mix

In addition to direct current (DC), a portion of alternating current (AC) is also available in the tunnel. Fan motors operate best on AC voltage, and the auxiliary substations also require a 230 Volt-AC wall outlet for the fire department. "We made it very clear at the beginning of the process that we wanted to build the ideal mix of systems with a power supply that was right," says Hans. "Systems that work on DC, we offer on DC. All rotating parts, on the other hand, work best on AC, so we offer a suitable solution for that too." By the way, know that the fans only start running in the event of an emergency, so they are far from large consumers.

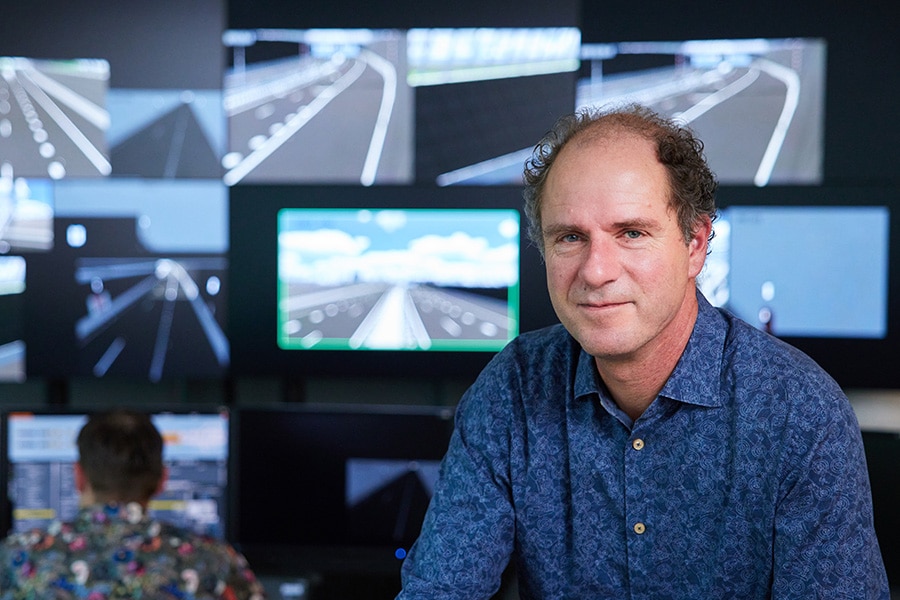

TWIN-16

You can think up a lot in the preliminary stages and put it on paper, but it has to work in the end. Reason for De Groene Boog to build a digital copy of the tunnel and all the installations. "Everything we build in real life was first built and tested digitally in the TWIN-16 model," Hans explains. "And in that we went pretty far. All 54 systems are in that digital model, which was interfaced with the controls and the control point of the road controller. With that, we were able to test the entire controls in advance and simulate all scenarios." Peter adds: "Besides 'digital certainty' about the operation of the installations, we were also able to test the DC installation in the field at an early stage. A section of the A16 was put into service earlier as the N209, whose lighting runs on DC voltage. If that had given problems, there was still enough time to fix things before the construction of the tunnel, but that proved unnecessary."

Norm reversal

The A16 Rotterdam is completely energy-neutral. The energy required is generated from three locations with a total of 11,000 solar panels. "Furthermore, we looked at all possible areas to save as much energy as possible," says Peter. "You might not expect it, but especially on sunny days extra energy is needed. Then the transition to the dark tunnel has to be made as small as possible and thus lights have to shine brightly. In the tunnel mouths, therefore, lighter asphalt has been chosen that reflects better and the walls have a reflective coating, so that less light is needed for the same effect. Furthermore, after extensive research in cooperation with the Department of Public Works, the existing lighting standard, based on luminaires from 1960, has been adjusted. This means we need less light to keep the tunnel safe."

Since last October 13, there has been power on the Rottemer Tunnel. "Until the end of December we are working on commissioning the power supply and then in the first quarter of next year we will put the network and controls live," says Hans. "Then we will commission and test the sub-installations, followed by a series of integral tests (Integral Site Acceptance Test, iSAT). Finally, the tests will be conducted from the traffic center in Rhoon, but by then we'll be toward the end of next year or early 2025. Then RWS will take over from us. RWS will also conduct the necessary tests and exercises and apply for the opening permit from the municipality of Lansingerland. All steps that are still necessary to open the A16 Rotterdam with Rottemerentunnel to traffic later in 2025."