When electrifying the construction site, also consider the RI&E and FAFS

Electric equipment is gaining in popularity. However, it is good to realize that a safe machine can be deployed unsafely and that an unsafe deployment can get in the way of a safe machine. Moreover, when electrifying the construction site and equipment, the RI&E and the FAFS organization change. This awareness is not always there, notice the experts at Aboma Inspections and Consultancy.

While electric equipment is gaining in popularity, the supply from manufacturers (OEM) is still quite limited at the moment, notes Bas van Gruijthuijsen of Aboma Inspections. "What you see is companies taking the initiative themselves to electrify equipment (or have it electrified). However, that has serious liability implications, because replacing the power source is considered a so-called 'major modification.' And that means you suddenly become the manufacturer of that machine and have to comply with all current regulations. This is generally heavily underestimated. From Aboma Inspections, we assist companies to take the right path so that the 'new' emission-free machine meets all set standards and requirements."

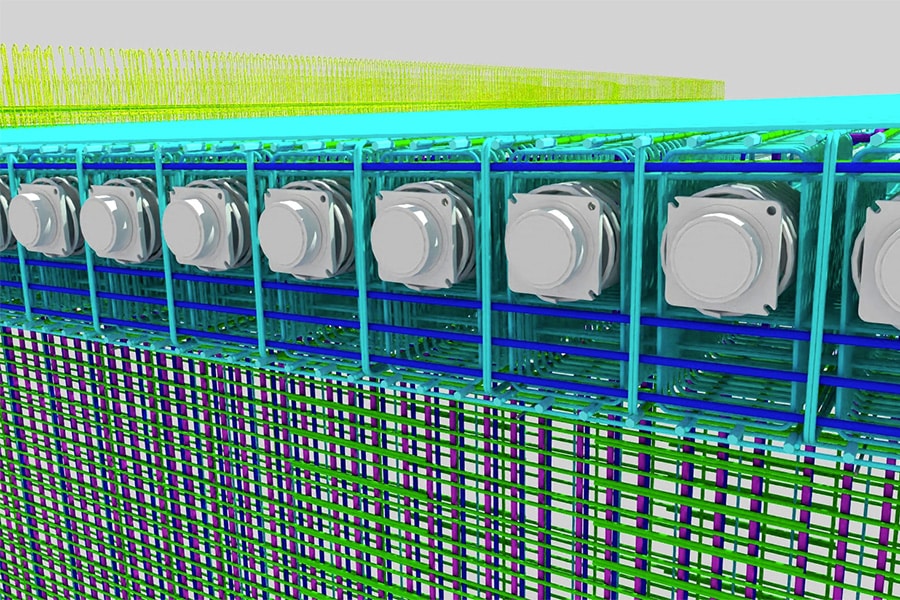

Energy supply

A safe electrical machine is one thing, but safe deployment is at least as important. "In the first place, this already has quite an impact on the construction site design," says Pieter Visser of Aboma Consultancy. "Just filling up the tank is no longer an option. People expect a charging point or power supply in the construction site. So that means the coordinating contractor has to organize the energy supply very differently. That seems like a simple step, but the electrical installation has to be critically examined. The amount of energy you demand from the grid becomes a sensitive issue. In just about every province, the power grid is already going or is going to be locked. Add to that the fact that power demand peaks during breaks and nights. Precisely at those times when no one is present. That has consequences for the FAFS and emergency organization."

Controlled burnout

So there are many hooks and eyes to the deployment of electrical equipment that should certainly not be underestimated. Aboma Consultancy has contacts with some safety regions. "Also for them there is still a lot unknown", Pieter knows. "The fire department is quite wary of electric equipment. You don't just pick up a burning 65-ton electric loading shovel to immerse it in a container. So they let it burn out in a controlled manner. And often there are several electric machines parked rigidly against each other, because the charging cable is no longer. In an emergency, it can get pretty expensive. So you have to include this in the RI&E: how much power do I put together around a charging point? Or should you place the equipment further apart, just like the rule that applies to a gas tank that has to be free around 4 meters. Things that are not taken into account but can have huge consequences."

Aboma organizes knowledge sessions on the electric construction site with some regularity. "The initial goal is to create awareness," says Pieter. "Think 'early bird sessions' about, for example, FAFS on the electrified construction site. We can make it very big and complex, but it starts with awareness and the realization that it's different from what we were used to. Then the questions come naturally."