Waterproof building pits thanks to horizontal water-glass injections

Underground construction with high groundwater levels requires virtually watertight building pits. The horizontal water inhibiting layers using water glass injections of Soil-ID Architectural Soil Injections are the solution. Patrick Wolfs tells how he and his partner revived the technique in 2009. Since then, the company has already completed more than 200 building pits.

As an alternative to underwater concrete, Soil-ID developed a modern version of an old method. With this specialized foundation technique you make building pits, without pumping and without lowering the groundwater level in the area. Wolfs: "We made the method much faster and industrialized it. With old installations you pumped 12,000 to 15,000 liters per day, but with our self-developed machines you reach 250,000 liters per day."

With microelectronics and sensor technology, monitoring has also improved. Wolfs: "This gives you more knowledge of the soil and shows that you have actually made what you promise." Soil-ID also thinks along with the total project: "For example, we advise on the drainage of the construction pit and explain why it is essential to choose gravity drainage with this technique."

Water glass injection technology

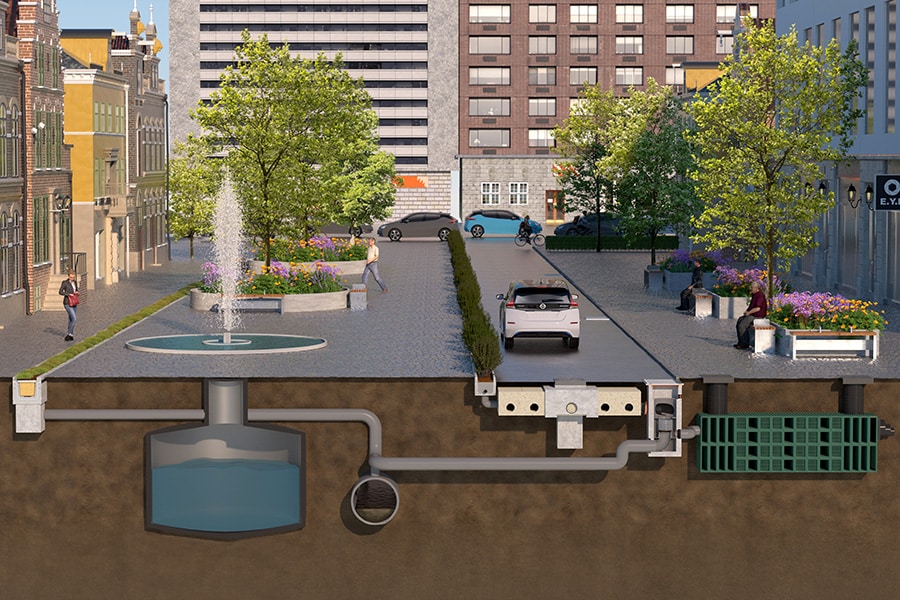

How does the water glass injection technique work? "Briefly, we demarcate the construction pit to be excavated with sheet pile, deep or soil mix walls. Then we pump water glass into the ground at injection points a few meters below the future floor of the building pit to be excavated." The water glass forms a dense water-resistant "carpet" of soil, water glass and hardener in the ground. "Then the soil above the soil valve is drained to drain soil and rainwater so that the pit can be excavated dry." Horizontal soil injections largely eliminate the need for well drilling.

The difference with underwater concrete

Horizontal injections have advantages over the often common method of underwater concrete. "If a natural water-inhibiting soil layer of clay is lacking, Soil-ID water-glass injections are a logical alternative."

The method is also attractive in terms of sustainability. "This technique emits much less CO2 out. The layer breaks down slowly, giving you even more environmental benefits." That's also good news for contractors and governments who are increasingly critical of groundwater lowering and other construction nuisances.

Undertunneling

A project Wolfs is very proud of? "We regularly do under-tunneling for ProRail. We make a total construction pit in one weekend, for a tunnel element or a cover plate. Without our method, that's much more labor intensive."

In addition to horizontal injections, Soil-ID also deals with soil stabilization with water glass, foundation repair and moisture control in building pits and existing buildings. "We are also increasingly making elevator wells in existing buildings. Think of modernizing a shopping center, with an escalator to the parking garage. Most basements are built below the water table. Making a hole in that watertight tank, for such an escalator, that requires specialists."