Striving for a 100% safe working environment

For 60 years, Aboma has been committed to increasing quality and safety in construction and infra by performing inspections and offering training. "Unsafe work has fortunately become socially unacceptable, but that does not mean we are already there," said Jeroen Lammertse, director of Aboma. "Our goal is to strive for a 100% safe working environment. That is an ongoing process. In view of future developments, such as the electrification of construction equipment, there will be other challenges."

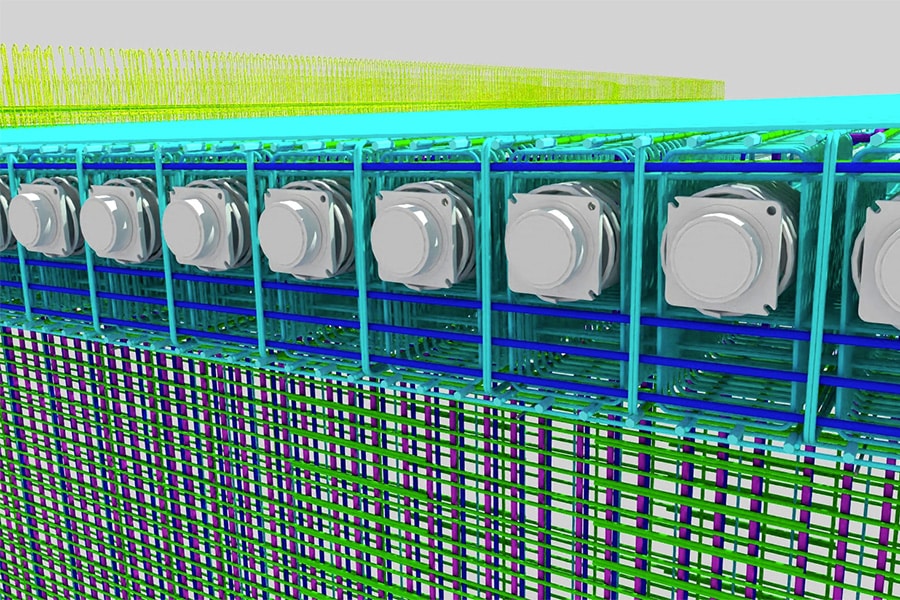

The electrification of construction equipment is increasing. "A logical development," thinks Lammertse, but at the same time he does worry about the level of knowledge among users. "People are very quick to pick up the gauntlet and modify a machine themselves. Don't forget that you then become the manufacturer of the device and thus take on all the responsibilities. In other words, you are responsible for the complete machine file. It is therefore important to gather the right parties around you to manage the process. We can support in this and assess the entire process for conformity and feasibility."

Sensory characteristics

Smell and sound are often important indicators when operating or locating machinery on a construction site, Lammertse knows. "Sensory characteristics that are mostly missing from electrical equipment. We all sometimes overlook this somewhat easily and I don't yet feel that a lot of attention has been paid to this. We will have to find a solution together to keep the construction site safe even with electrical equipment. For example, by adding other sensory features, such as a light or a certain sound signal. We are enormously active in various consultative bodies and working rooms on the "future of the construction site" and bring precisely these "preconditions" into the limelight in order to start the discussion. In addition, we also work together with BOVAG, because electrification goes beyond the construction site, but also affects transport to and from the construction site."

Aboma Foundation

Aboma inspects equipment according to legal schedules. "This also requires social support. The schedules are drawn up together with trade associations, employee organizations and users," Lammertse explains. "What we unfortunately have to note is that the latter group is increasingly dropping out. I'm sure it's not all unwillingness, but it's also essential from the user side that good representation is guaranteed. After all, a 100% safe working environment is something you create together. Inspection and certification is merely demonstrating that you meet the minimum requirements. That is different from the desire to work as safely as possible. Slowly but surely, people are aware of this and are willing to invest in it. The group of companies that really strive for a 100% safe working environment is growing. As Aboma, we also invest in this. Our profits go in large part to the Aboma Foundation, which funds projects to increase safety in construction and infra. A win-win."