'Pouring underwater concrete is a matter of good planning'

1,675 m3 of underwater concrete

As specialists in civil underwater construction, the people of DISA International dive underwater for the construction, maintenance and repair of large civil infrastructure projects. They have already done so for projects such as the Maasdelta and Holland Tunnel, De Groene Boog and OPENIJ, and now for the Afsluitdijk. The company is known as the global underwater specialist.

"If you calculate over a period of about five years the amount of underwater concrete that we pour, we end up with an average of 100,000 cubic meters per year," says Cecil de Groot, head of the Afsluitdijk contractor at DISA. "A huge amount that very few companies achieve. We do this for the construction of tunnels, parking garages and locks, among other things. Sometimes as much as 10,000 cubic meters can go through per dump, which is equivalent to about a thousand trucks. For the Afsluitdijk project, 1,675 m3 of underwater concrete was poured in the deepest construction pit at Den Oever, a construction pit about 20 meters deep. We also poured underwater concrete at the existing sluices on the Wadden Sea side, a total of 2,000 m3. Pouring underwater concrete is always a matter of good planning. The pouring has to go on continuously; you can't stop halfway through. In all our projects and so for the renewal of the Afsluitdijk, our customers appreciate our innovative, safe and reliable approach."

Assist divers

In 2018, DISA started underwater work at the existing culverts at Den Oever. That immediately presented a nice challenge for underwater concrete pouring. "The space was so limited that the concrete pump really had nowhere to stand. We ended up placing a 63-meter-long pump with boom on the closed lane that went over the lane in use. Through additional pipes, the concrete went to a second concrete pump on a pontoon."

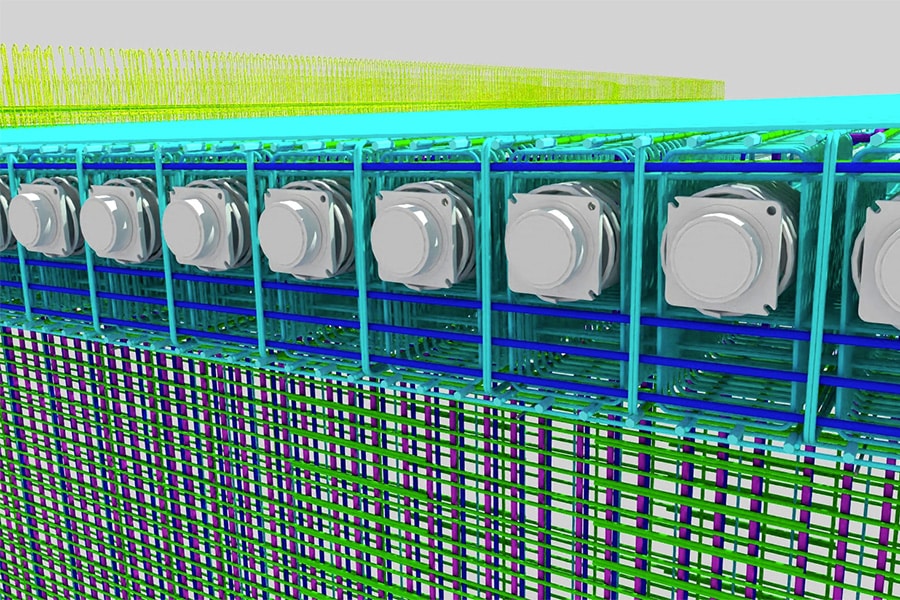

A nice challenge awaited DISA again this year, again at Den Oever. Two construction pits on the Wadden Sea side have a 10 percent slope. The concrete does not stay in place on such a slope. "We solved that by placing reinforcement baskets that ensured that the slope of the concrete remained in place. We also made the consistency of the concrete slightly thicker. In a number of construction pits, divers had to come in to assist. In the excavation there were many places where the crane could not reach. Divers then help with low-pressure spraying and suction with a pump."