Innovative in plastic for 36 years

The plastics market holds no secrets for Rombouts Kunststof Techniek (RKT). The Tholen-based company has been innovating in the world of plastics processing for 36 years and offers a suitable solution for the most diverse situations. The methods and products developed in-house are praised internationally, even by processors of steel piping systems. An interview with director Marcel van Pagee and project manager Lennard Berrevoets.

We do everything in plastics except doors and frames, Van Pagee outlines RKT's field of work. "We process both thermosets and thermoplastics or a combination of both. The latter is quite unique in the world of plastics processing. In the underground infrastructure, our activities include realizing (complex) pipe networks for the transport of (waste) water, gas and heat. This mainly involves joining thermoplastics, in which mirror welding is by far the most important technique. We can do this on site in the field up to diameters of 1,200 mm. In our workshop we even go up to 2,000 mm. If possible, we prepare the pipe sections prefabricated at one of our production sites in Tholen or Zwolle."

Tracked welding machines

For on-site welding, RKT has several welding containers at its disposal. "That way, we can also adjust the conditions in the field to our liking for the most optimal joint," says Van Pagee. "In addition, we have developed two self-propelled welding machines that allow us to weld an entire pipeline route without additional outside help. The machines are on tracks, so they can get out of the way even in fairly impassable terrain." In 36 years, RKT has made some great developments. "We think along with our customers and try to find an appropriate solution for every situation. A great example is our welding machine that allows us to process egg-shaped thermoplastic pipe for sewer applications."

Combinations

Thermoplastics are used for underground pipe work in the infra, among other things. "The thermosets we process are often used in industry where chemical resistance is required or in fire-fighting water facilities," Berrevoets knows. "Where a certain strength or pressure resistance is required, we also often apply thermosets or a combination of both disciplines. We are able to provide thermoplastic pipe sections and fittings with a GRP outer jacket in accordance with the German DVS standard. A combination that is not applied by very many parties in the Netherlands and certainly not under one roof."

PUPP Lining

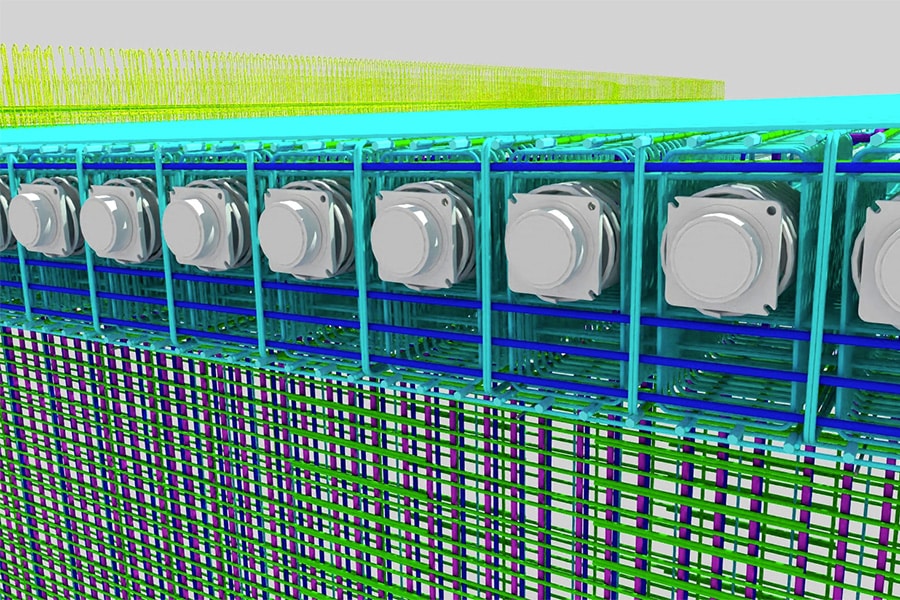

In addition to plastic piping, steel piping systems are also widely used in underground infrastructure, especially when higher pressures are involved or in HDD controlled drilling. In that market, too, RKT is proving its added value. Says Berrevoets, "We have developed a coating system to protect steel welds from corrosion: PUPP Lining. The coating system can be applied cold on site at any desired location and is qualitatively equivalent to a factory coating." Van Pagee adds: "Since PUPP Lining has been in existence, we have already made more than 24,000 (!) joints in diameters ranging from 100 to 2,000 mm. Both at home and abroad, this proven methodology is in high demand."

Speaking of innovative, RKT is already anticipating the energy transition with the SWAPE barrier. Says Van Pagee, "This methodology builds on PUPP Lining and is a system for segmenting insulated pipes in district heating - popularly called a water lock. This so-called 'water lock' is just one of the generic systems in RKT's product range. A system has been developed for all common transitions and material combinations in district heating to provide protection for joints, pipe sections and fittings. And so we have many more unique products and applications to complete the most complex jobs in plastic. We like to be challenged."