Fittings without limits

Since 1948, the Austrian company AGRU Kunststofftechnik GmbH has been developing and producing high-quality plastic products that are used worldwide in the earth, industrial and infrastructure sectors. With the CUSTOMIZED PARTS product line, the company presents its next milestone: customized fittings for pipe systems with outside diameters from 20 mm to 3,500 mm. With these, special isometries and high pressure classes can be realized - an additional flexibility that is especially appreciated by designers and civil engineers.

Wide range of materials

AGRU is able to offer a wide range of materials to meet diverse requirements. The range includes PE 100-RC, PP, PVDF and high-performance plastics such as ECTFE. Thanks to electrically conductive materials and advanced fluoropolymers, the portfolio covers not only standard applications, but also highly specialized projects where chemical resistance or purity is a requirement. AGRU's guiding principle is: "The best material for every need. For example, PE 100-RC is ideal for underground gas and water pipes without having to dig a trench, while PVDF-UHP and ECTFE are used in the semiconductor and pharmaceutical industries.

All products are subject to strict quality controls in accordance with ISO 9001, ISO 14001 and ISO 45001. To meet worldwide demand for cleanroom-compatible solutions, AGRU cooperates with fab shops in Austria, Dubai, Korea, China, Singapore and the US. Among other things, these facilities produce ultrapure pipe isometries for applications with the highest purity requirements. AGRU is thus responding to growing markets in the high-tech industry, where high-purity piping systems enable semiconductor production.

Digital design and modern manufacturing

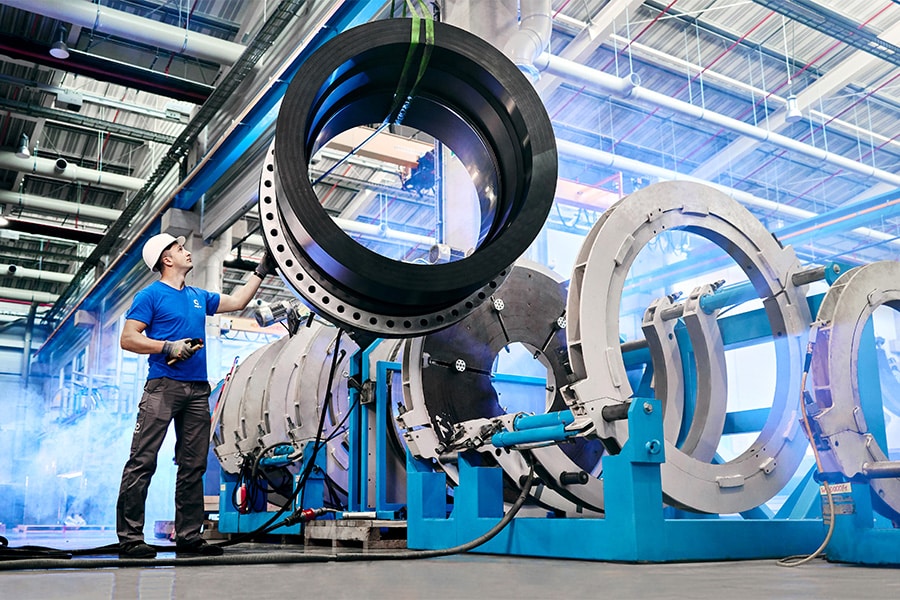

AGRU uses CAD and BIM-based design tools followed by precise CNC milling and welding techniques such as infrared welding, butt welding, sleeve welding and extrusion welding. (FEA) finite element analysis and hydrostatic pressure testing ensure that each part is perfectly matched to its application. Thanks to in-house production facilities, the company can produce fittings and special components up to 3,500 mm in diameter - even for particularly complex geometries or cleanroom requirements.

Versatile application areas

The value of the CUSTOMIZED PARTS is demonstrated by a modernization project at a wastewater treatment plant, where CNC-machined PE 100-RC electro sockets provided a homogeneous and leak-free piping system, with minimal installation work and with very tight installation conditions. But the application possibilities extend far beyond these example projects: pressure lines for horizontal directional drilling, ultrapure process lines in clean rooms and chemical applications with aggressive media are also part of the portfolio.

By 2025, AGRU plans to further expand its technological lead. "Our fittings combine expertise from thousands of projects with innovative technology," emphasizes Ing. Albert Lueghamer, Technical Director. "This guarantees high-quality solutions precisely tailored to our customers' needs - in terms of size, purity and precision."