Our structural concrete solutions are uniquely customized

If somewhere the hard side and the soft side are nicely balanced, it is at contracting company Gebr. Schouls. On the one hand, there are those heavy, concrete structures - such as the Catharina Bridge in Leiden and the overpass over the A12 Utrechtsebaan in The Hague - made by people who want to lead the way and have ambition. But just as much attention is paid to safety, good relations and Social Return.

Contracting company Gebr. Schouls is celebrating its 90th anniversary this year. A milestone for which many companies have to look far ahead. What began in the thirties as a local street builder has now grown into a specialist in concrete, road and hydraulic engineering. Gebr. Schouls realizes projects on and near the water for municipalities, water boards, provinces and companies. The clients determine what they leave to Gebr. Schouls. "We can handle a traditional RAW contract, but also Design & Construct and Bouwteam contracts," says Leen van Belen, project manager at Gebr. Schouls.

Experience and know-how

It is precisely with the latter contracts, in which Gebr. Schouls itself devises the best-fit solution and then takes charge of calculation, design, engineering, production and execution, that customers also benefit from the broad experience and great expertise present within Gebr. Schouls. "Of course, every project is unique," Van Belen explains. "Each location brings specific challenges. But we do have many projects on which we can look back with satisfaction and for many issues for which we have already come up with a solution. Our solutions are founded on expertise and comply with applicable standards."

Crossing over the A12

Then surely there is a project Van Belen is personally proud of? "One project that I will point out to my children is the green overpass over the A12. This is one of the gateways to The Hague, which also connects the green areas Koekamp and the Haagse Bos. For this, Gebr. Schouls has built a sleek and slim artwork with trees and vegetation, a bicycle path and a footpath, also suitable for (heavy) traffic. The work was tendered with a D&C contract and we were awarded it on the basis of the Most Economically Advantageous Tender. The biggest challenge was the deadline. The overpass had to be completed within five months and with eight weekend closures of the A12. But the result is fantastic and perfectly balanced with the surroundings."

Lasting relationships

Employees who have found Gebr. Schouls once, do not leave here easily. Employment contracts of thirty and forty years are no exception here, keeping accumulated knowledge on board. "Clients signal that. We bring our ideas with confidence and that creates trust. The same interaction plays out with our suppliers and subcontractors. We also have lasting ties with them."

Meeting place Maassluis

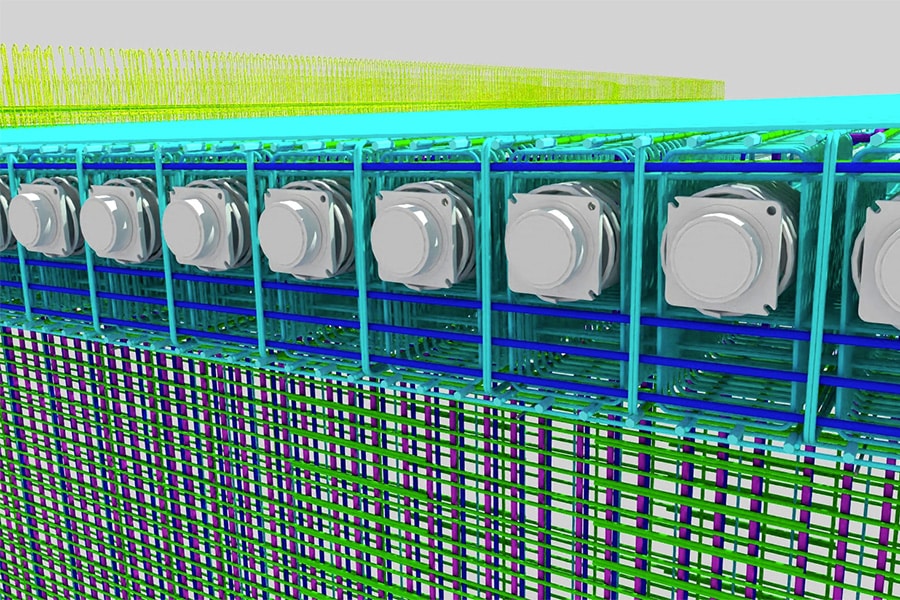

A durable contact pur sang is Waco, a specialist in precast concrete elements and - like Gebr. Schouls - a company of respectable age. Here, too, knowledge and experience have been passed on from one generation to the next for decades. At the same time, Waco continues to renew and improve its insights, manufacturing processes and products. This attitude makes Gebr. Schouls and Waco something of a soul mate. "Together with Waco, we made several bridges and the overpass over the A12. And for the municipality of Maassluis, we worked with them to create a meeting place in a dike body in the shape of the prow of a ship. This required unique pieces of concrete, each with a different shape. Both the molds and the transportation of the concrete elements presented challenges. Using a huge crane, we ended up lifting the elements onto a ship and transporting them across the water to their destination."

Sustainability

As in the entire construction industry, sustainability has become increasingly important at Gebr. Schouls. Eye for the environment, attention for local residents, the wider environment and society in general are now an integral part of the daily policy. Everyone within Gebr. Schouls keeps a close eye on the developments in the field of sustainability and highlights opportunities for improvement.

Van Belen: "We have now reached a point where you can see this sustainable policy reflected in everything. The equipment has been replaced by sustainable equipment; the energy supply on the construction sites is no longer provided by diesel generators but, where possible, by fixed power connections and Esavers, whereby the use of diesel generators is kept to a minimum; waste is separated; we are ISO 14001-certified and operate on step five of the CO2 performance ladder. This high step can only be reached if environmental awareness is part of the corporate culture. Everyone in the company must then want to make a conscious contribution."

Circularity

"Profit is not just euros for us," Van Belen then continues. "The sustainable policy and the good feeling we get from this is also profit for us. Not for nothing are we members of two concrete chains. Within these chains - 't Groene Hart and Haaglanden - municipalities, suppliers and contractors are jointly looking for opportunities to build circularly, allowing us to make great strides in this area. We are now selecting materials based on circularity. Water boards, municipalities and other government agencies are also increasingly making this a requirement, so it also works to our own advantage."

Social Return

Within the sustainable policy there is also a lot of attention for people. In this context, Gebr. Schouls is a recognized training company. Young employees can count on support if they want to learn and work within the organization. "Virtually all new employees join our company through an apprenticeship or traineeship. The mutual involvement between employees is high and results in a kind of family feeling. For example, one employee, from Angola, came in here as an apprentice. Now he works as a foreman and is totally integrated in the Netherlands and at Gebr. Schouls. He is an ambassador for the industry and as part of training he visits (primary) schools to tell his story there. Social return is a part of corporate social responsibility for us."