State-of-the-art concrete slab plant for automatic production of buckled slabs and angle slabs

They certainly have not been idle at Zwaagstra Beton in Hoogeveen. In the past three years, the company has built a new production site no less than twice, as an expansion of the existing plants. "Not only the demand in numbers is increasing," says André Veerkamp, account manager at Zwaagstra, "but also the demand for quality and new products."

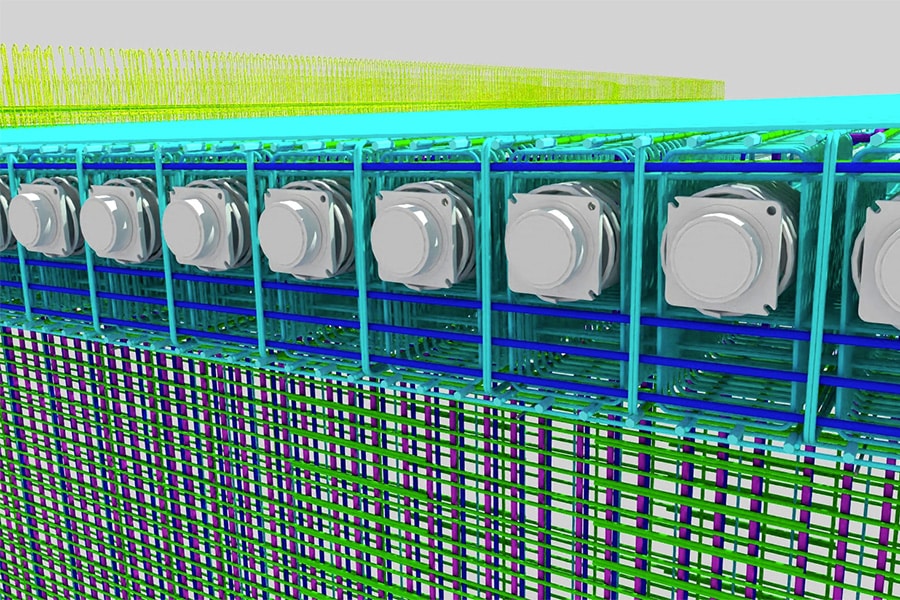

Where Zwaagstra first put into operation an impressive production hall for retaining and silo walls, a concrete slab plant followed just a year and a half later. "Equipped with the most modern production machines that are set up in such an innovative way that it contributes to an optimal logistical process," according to Veerkamp. "With this we are again significantly expanding our production capacity."

Beautiful production process

The factory hall is set up with a carousel in which the plates are produced almost entirely automatically. "As many as nine dancing robots perform all kinds of operations," Veerkamp begins. "From applying the formwork oil to brushing the broom structure into the slab, everything is automated. A wonderful process," Veerkamp believes.

Studded plates

The brushed concrete slabs have a structure for extra grip, making them suitable for, among other things, footpaths, walkways and storage areas where there is a lot of transport or foot traffic. All steel molds with dimensions 200×200 cm were produced in-house by Zwaagstra. "Meanwhile, we have also started producing 20-cm-high molds because the demand for thicker concrete slabs is increasing. Construction traffic is getting heavier, and thickness 20 cm can carry an axle load of 40 tons. By the end of this year we will have a warehouse full of new molds and will be able to fully utilize capacity." Of course, all concrete slabs rolling out of this plant are again KOMO certified, as we have come to expect from Zwaagstra.

Concrete slabs with steel angle bar

Next year, Zwaagstra will start producing not only the cast-in-place slabs but also cast-in-place concrete slabs with a steel angle line in thicknesses of 14, 16 and 20 cm. "As soon as we have a large stock of angled line, we will draw the attention of the civil engineering market to this. We will also be more active on the German market next year. We have hired a very experienced Infra man to strengthen Infra sales and to pioneer in Germany," Veerkamp concludes.